10

FAM3200

ARMORED VARIABLE AREA PURGEMETER | CI/FAM3200-EN REV. D

… 6 Electrical connections

… Analog indicator with alarm signaling

unit

Switching amplifier

Additional switching amplifiers are needed to operate the alarm

signaling units.

See

Switching amplifier

on page 10 and the ‘Ordering

Information’ section of the data sheet for further information.

Specifications

Power supply

230 V AC, +10 % /

−15

%, 45 to 60 Hz

115 V AC, +10 % /

−15

%, 45 to 60 Hz

24 V DC, +10 % /

−15

%

Output

One or two switching relays with potential-free

changeover contacts

Switching capacity

Maximum 250 V, maximum 4 A, maximum 500 VA

Maximum permissible

cable length

Between the switching amplifier and alarm

signalling unit:

300 m (984 ft)

Permissible ambient

temperature range

−

20 to 60 °C

(−4

to 140 °F)

Electrical connection

Screw terminals, maximum 2.5 mm

2

(14 AWG)

Type of assembly

35 mm top-hat rail in accordance with

EN 60715:2001

IP rating

IP 20 in accordance with EN 60529

Weight

approx. 150 g (0.3 lb)

Analog indicator with transmitter

Specifications

Output signal

4 to 20 mA, two-wire technology

Power supply

maximum 30 V DC

Input Current

maximum 30 mA

Connection type

Cable, 2-

wire, brown (+) / blue (−), length

1.75 m (5.74 ft)*

Ambient temperature range

−

20 to 40

°C (−4

to 104 °F)

Design

Angular position transmitter in two-wire

technology

* Other cable lengths available on request.

7

Commissioning

CAUTION

Risk of burns due to hot measuring media

The device surface temperature may exceed 70 °C (158 °F),

depending on the measuring medium temperature!

• Before starting work on the device, make sure that it has

cooled sufficiently.

During commissioning of the flowmeter, observe the following

points:

• The ambient and operating conditions (pressure,

temperature, power supply) must correspond to the

details on the name plate and the specifications.

• Open the shut-off valves slowly to prevent pressure

surges that can damage the flowmeter.

• For liquid measurement media, vent the piping if

necessary.

• For devices with alarm signalling units, set the units to

the required switching points.

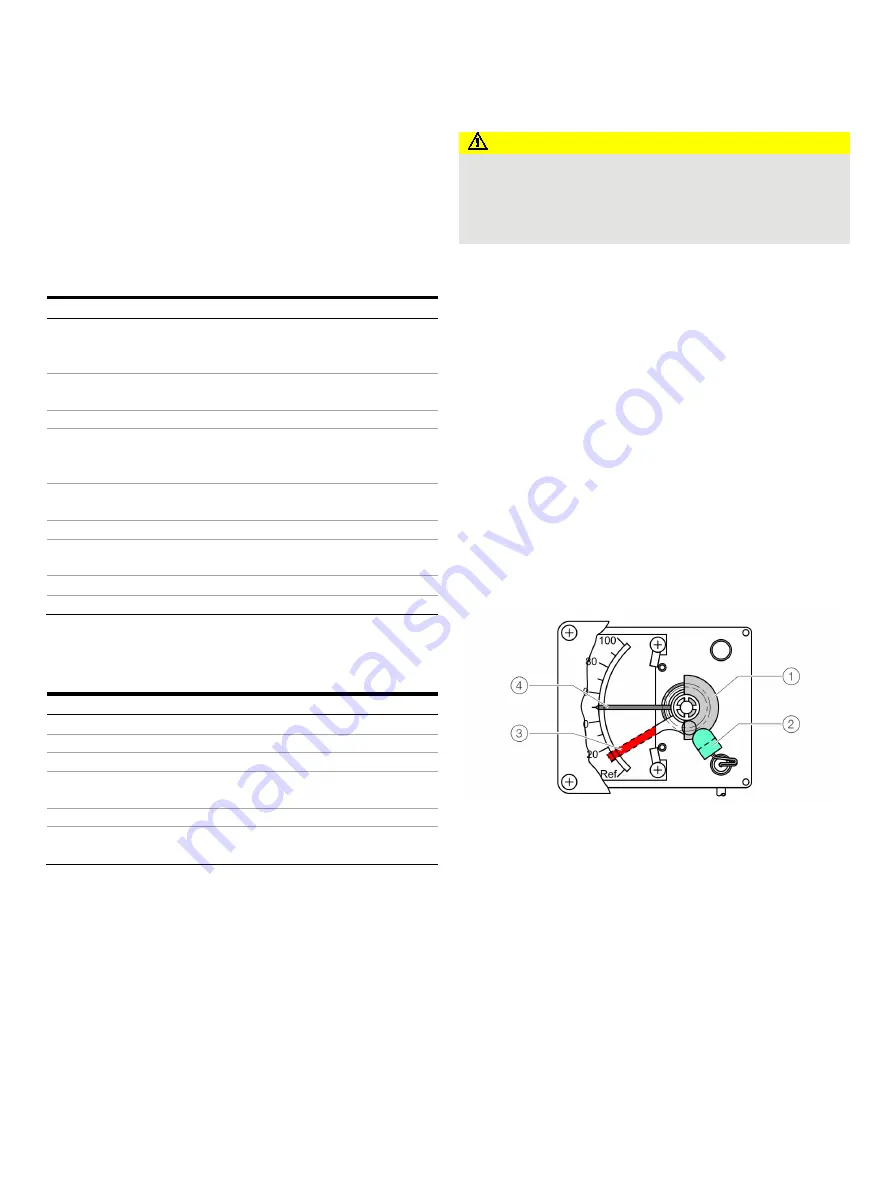

Adjusting the alarm signalling unit

The alarm signalling unit is designed as a proximity switch. When

inserted in the proximity switch, the metal tag initiates the

switching process. The switching point can be adjusted with a

screwdriver.

1

Metal tag

2

Alarm signalling unit (proximity

switch)

3

Alarm setting

4

Pointer

Figure 5: Single alarm (example)

1.

Unscrew the housing cover.

2.

Adjust the alarm setting to the required switching point

using a flat-bladed screwdriver.

3.

Screw on housing cover.

Operating instructions

If there is a chance that safe operation is no longer possible,

take the device out of operation and secure it against

unintended startup.