14

ABB i-bus

®

EIB / KNX

System setup

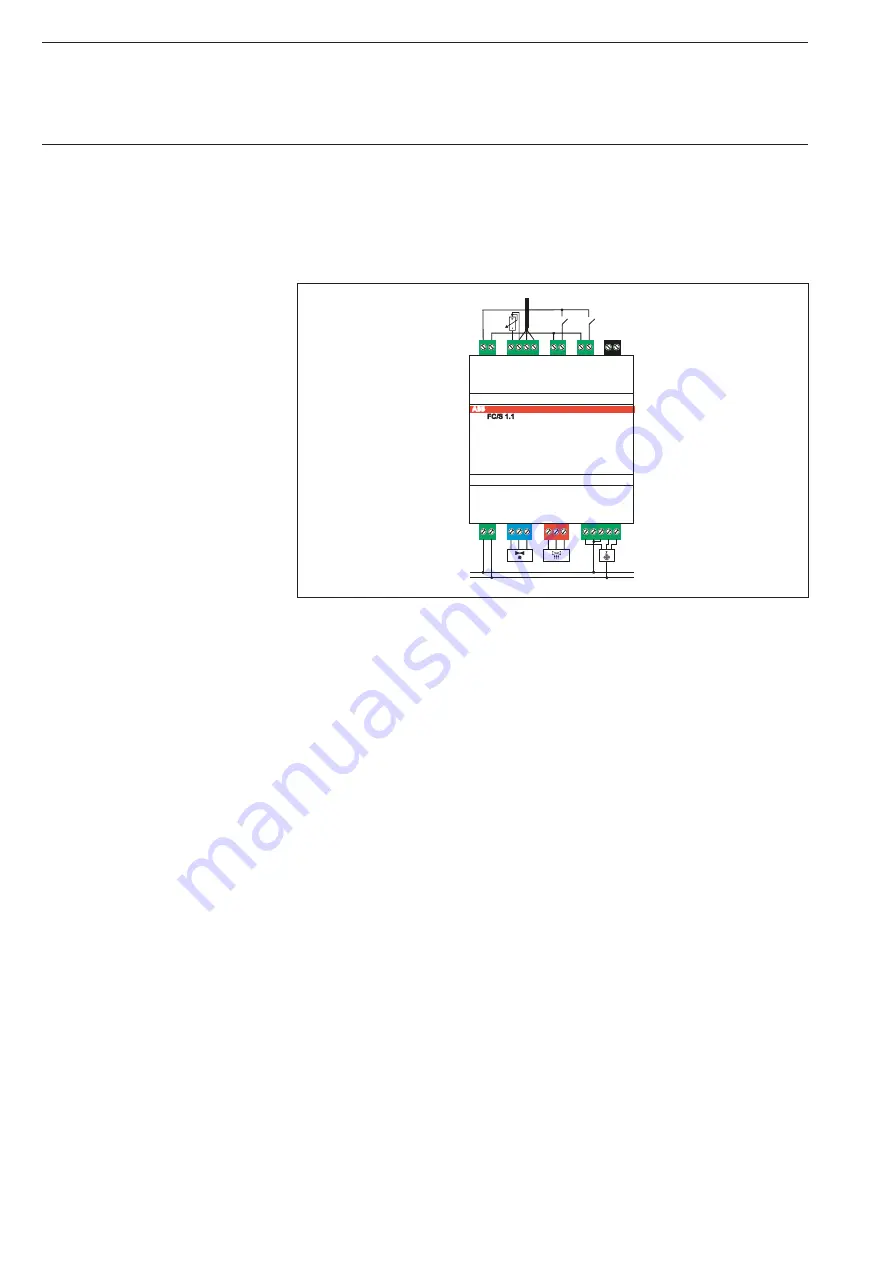

In “stand-alone” mode, the Fan Coil Controller FC/S 1.1 takes over the

recording of the actual temperature, complete control, the setting of the

heating and cooling valves as well as the switching of the fan outputs.

To do so, the temperature sensor TS/K 1.1 must be connected to the

Fan Coil Controller (see Fig. 7).

Fig. 7: Fan Coil Controller as “stand-alone”

The setpoint adjustment is carried out via a potentiometer which can be

connected directly to the Fan Coil Controller. To take the drip tray monitoring

and the window contact into account, the sensors can be connected

directly to the Fan Coil Controller.

Configuration as a stand-alone device

To configure the Fan Coil Controller as a stand-alone device, the following

parameters must be set:

– Parameter:

Sensor for measuring the actual temperature

(parameter window “Actual temperature”)

Option: “local”

– Parameter:

Setpoint adjustment

(parameter window “Setpoints 1”)

Option: “local”

Application and planning

3.2.3

Fan Coil Controller

as „stand-alone“

1

3

L

N