•

Always

tighten the joint by hand,

and never use pneumatic tools.

•

Use the

correct tightening technique

, that is

do not

jerk. Tighten the screw

in a slow, flowing motion.

•

Maximum allowed total deviation from the specified value is

10%

!

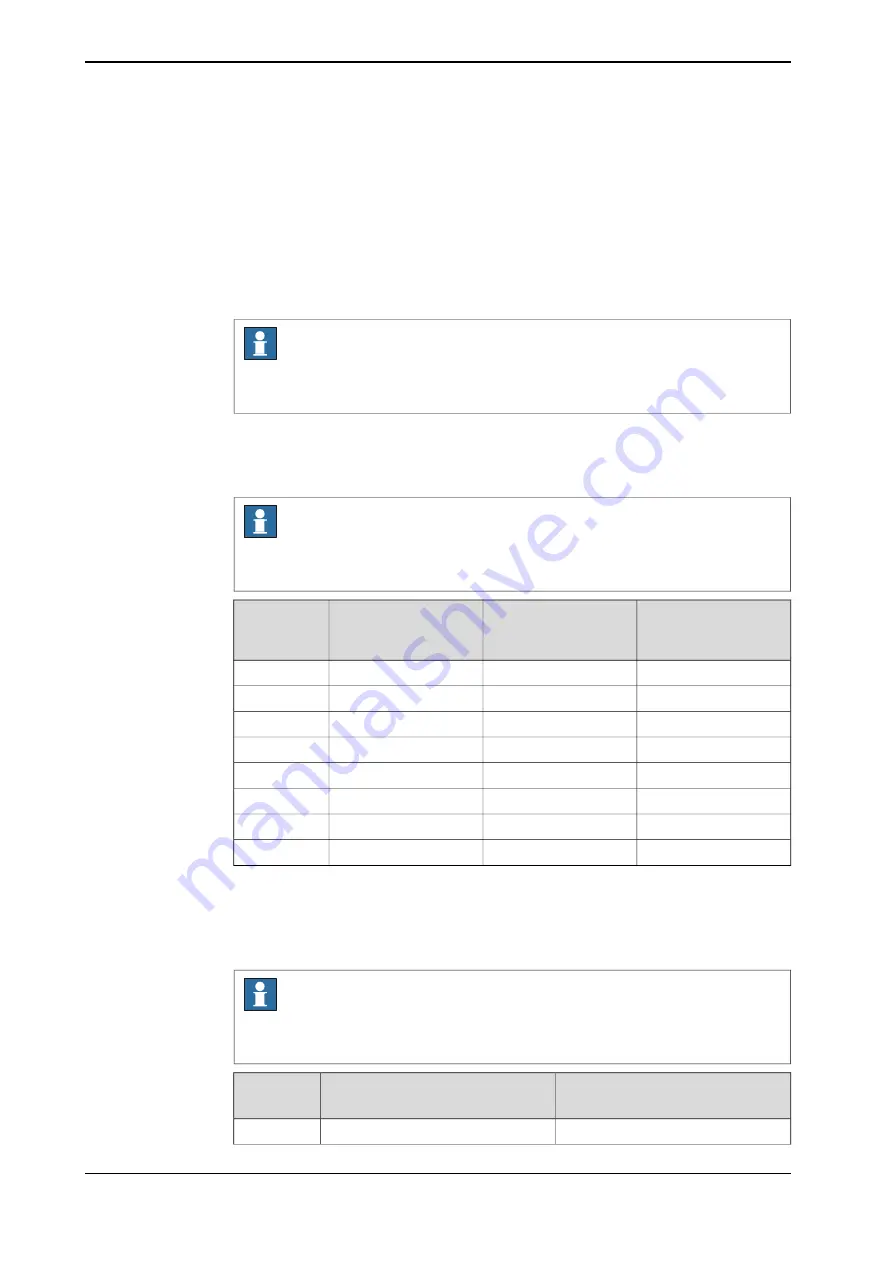

Oil-lubricated screws with slotted or cross-recess head screws

The following table specifies the recommended standard tightening torque for

oil-lubricated screws

with

slotted or cross-recess head screws.

Note

A special torque specified in the repair, maintenance or installation procedure

overrides the standard torque.

Oil-lubricated screws with allen head screws

The following table specifies the recommended standard tightening torque for

oil-lubricated screws

with

allen head screws.

Note

A special torque specified in the repair, maintenance or installation procedure

overrides the standard torque.

Tightening torque (Nm)

Class 12.9, oil-lubric-

ated

Tightening torque (Nm)

Class 10.9, oil-lubric-

ated

Tightening torque (Nm)

Class 8.8, oil-lubricated

Dimension

-

-

6

M5

-

-

10

M6

40

34

24

M8

80

67

47

M10

140

115

82

M12

340

290

200

M16

670

560

400

M20

1150

960

680

M24

Lubricated screws (Molycote, Gleitmo or equivalent) with allen head screws

The following table specifies the recommended standard tightening torque for

screws lubricated with Molycote 1000, Gleitmo 603 or equivalent

with

allen head

screws.

Note

A special torque specified in the repair, maintenance or installation procedure

overrides the standard torque.

Tightening torque (Nm)

Class 12.9, lubricated

Tightening torque (Nm)

Class 10.9, lubricated

i

Dimension

35

28

M8

Continues on next page

176

Product manual - Feather Duster V2

3HAX010000210 Revision: A

© Copyright 2018 ABB. All rights reserved.

7 Reference information

7.3 Screw joints

Continued

Summary of Contents for Feather Duster V2

Page 1: ...ROBOTICS Product manual Feather Duster V2 ...

Page 12: ...This page is intentionally left blank ...

Page 168: ...This page is intentionally left blank ...

Page 172: ...This page is intentionally left blank ...

Page 180: ...This page is intentionally left blank ...

Page 188: ...This page is intentionally left blank ...

Page 190: ......

Page 191: ......