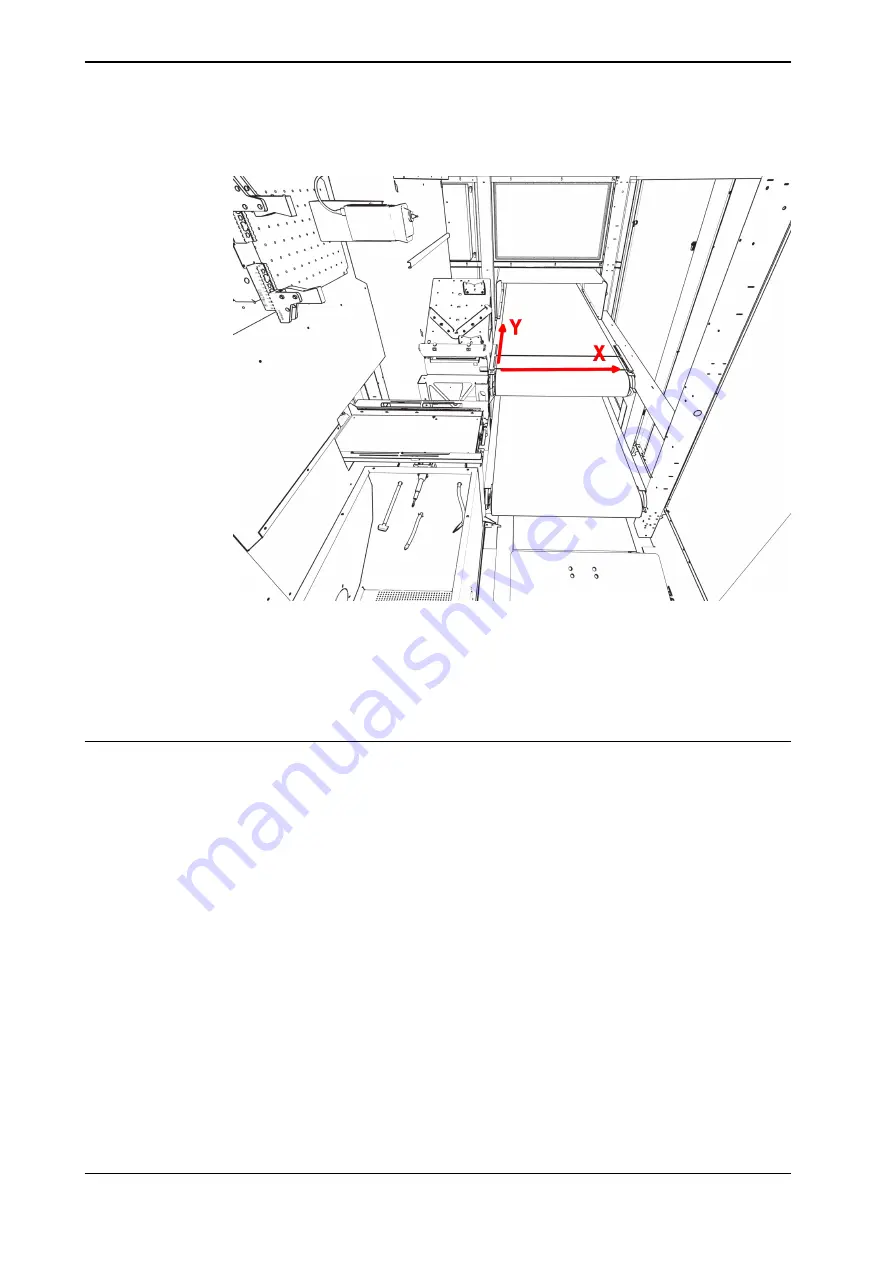

Approximate positioning of wCamera1 in the FlexLoader SC 6000.

xx1900000366

Finally, check the calibration by the following simple test.

Move the robot calibration tool tip to point x=0, y=0, z=0 in wCamera1. Use the

mouse curser coordinate display in FlexLoader Vision and point at the image of

the calibration tool tip. The displayed value should be close to x=0, y=0.

Outconveyor coordinate system wFeederOut

Coordinate system for leaving on outconveyor. The X-axis is above the idler roller

shaft, the Y-axis is at the left belt edge and in the direction of movement of the belt,

and the Z-axis points upwards. Perform a standard 3-point calibration.

Afterwards, call the calibration routine CalibSpeedFeederOut. Depending on the

use of the system, the point-of-interest, pLeaveFeederOut, is used differently. In

Continues on next page

64

Product manual - FlexLoader SC 6000

3HAC051768-001 Revision: D

© Copyright 2014-2020 ABB. All rights reserved.

4 Commissioning

4.4.2 Calibration of the coordinate systems

Continued

Summary of Contents for FlexLoader SC 6000

Page 1: ...ROBOTICS Product manual FlexLoader SC 6000 ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 78: ...This page is intentionally left blank ...

Page 172: ...This page is intentionally left blank ...

Page 174: ...This page is intentionally left blank ...

Page 176: ...This page is intentionally left blank ...

Page 178: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 186: ...This page is intentionally left blank ...

Page 192: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 283: ......