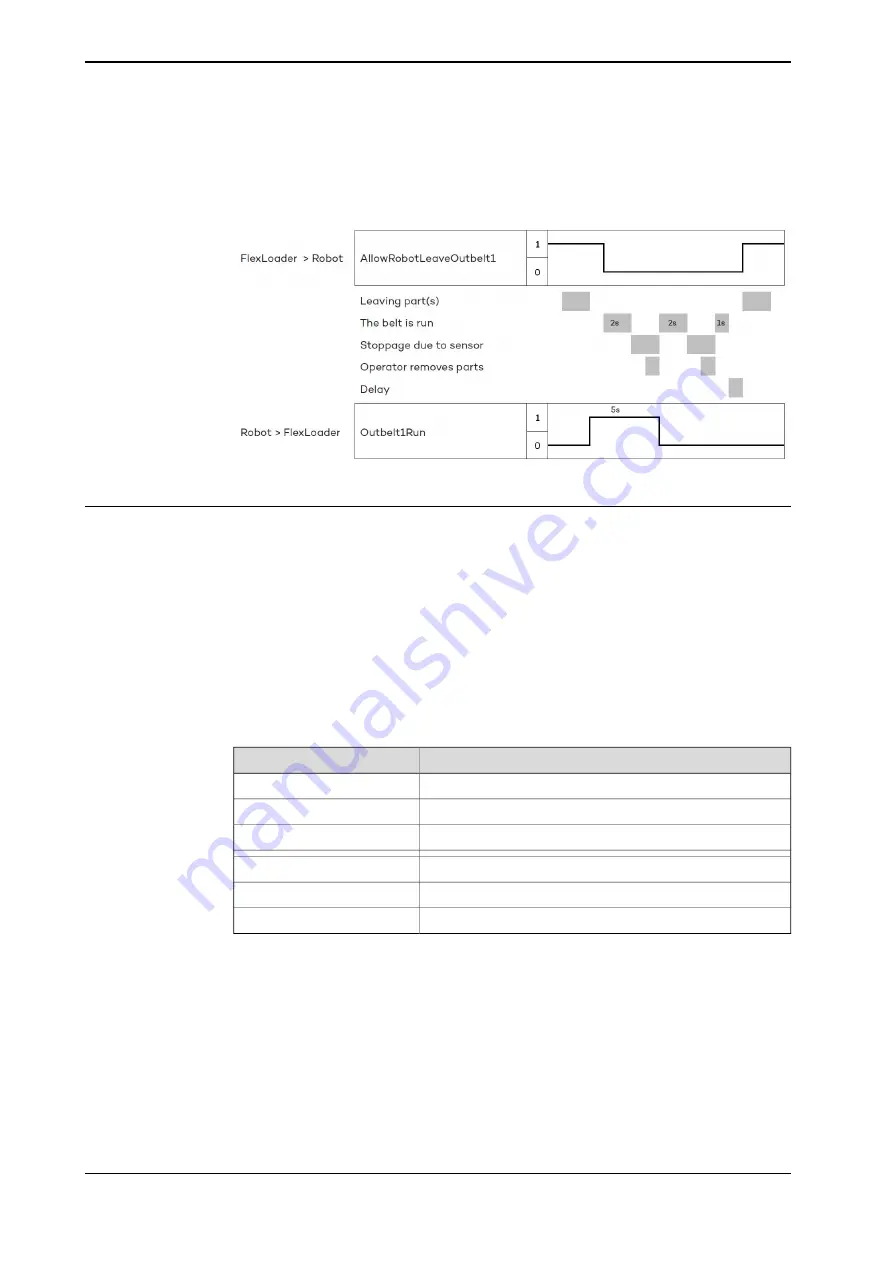

Outconveyor

During normal operation, signal exchange to robot occurs according to the following

handshaking sequence:

xx1800000185

Machine tool interface

As standard, the FlexLoader SC 6000 is delivered with the following functional

interface capability:

•

ABB CI502 series I/O node connected to the robot PROFINET bus.

•

Digital 24 V I/O interface (16 general inputs, 16 general outputs).

•

The physical interface is constituted by terminal blocks in the control cabinet.

•

The I/O node is physically located in the FlexLoader SC 6000 controller

cabinet.

Optionally, customer specific functional interface and I/O solutions can be used.

The following signals are defined for general use.

Description

Name

Spare input signal

diSpareInterface1

...

Spare input signal

diSpareInterface16

Spare output signal

doSpareInterface1

...

Spare output signal

doSpareInterface16

82

Product manual - FlexLoader SC 6000

3HAC051768-001 Revision: D

© Copyright 2014-2020 ABB. All rights reserved.

5 Interface

5.2 Function interface

Continued

Summary of Contents for FlexLoader SC 6000

Page 1: ...ROBOTICS Product manual FlexLoader SC 6000 ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 78: ...This page is intentionally left blank ...

Page 172: ...This page is intentionally left blank ...

Page 174: ...This page is intentionally left blank ...

Page 176: ...This page is intentionally left blank ...

Page 178: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 186: ...This page is intentionally left blank ...

Page 192: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 283: ......