7.2 FlexLoader application functionality

Overview

The FlexLoader SC 6000 application code handles the complete workflow of parts

in the cell (e.g. unloading and loading of parts, option handling, picking from

inconveyor and leaving on outconveyor).

The application code consists of a basic executable skeleton, which must be

modified by the integrator in order to match the actual application. However, the

basic structure should be followed to ensure smooth operation.

Main structure

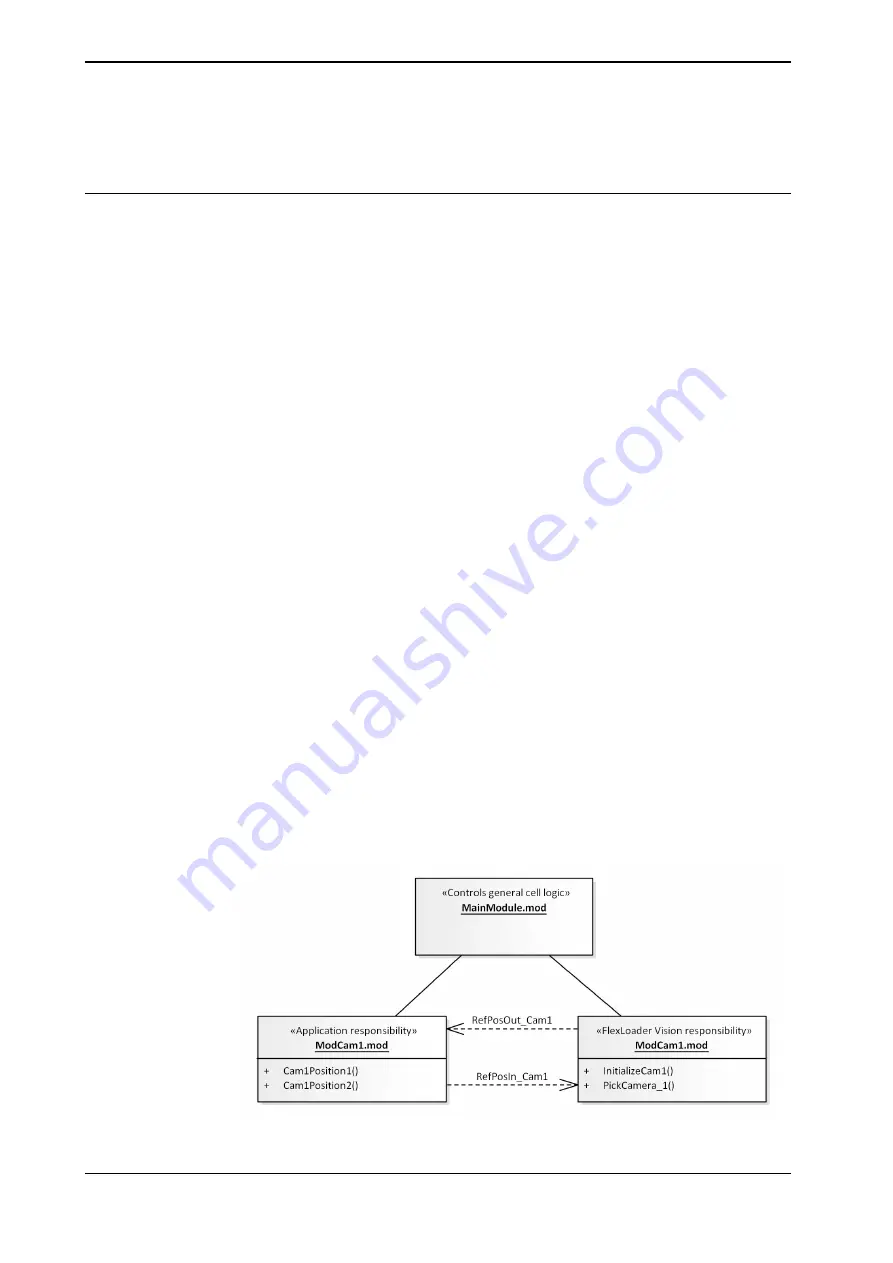

Main.pgf and MainModule.mod are automatically loaded into the controller when

a part is started from FlexLoader Vision. During the following initialization, project

modules with part specific information are loaded. This happens upon every start

(if not configured otherwise, see FlexLoader Vision ConfigurationEditor).

MainModule.mod is always the same for all parts and all operating modes of the

robot cell. MainModule.mod is responsible for loading the modules that are linked

to the parts to be run. Below, these are called PartCamX for a general reference

to any PartCam module, or specifically PartCam1 for parts to be run using camera

1, PartCam2 for parts to be run using camera 2, and so on. These files can be

renamed according to project needs.

Cell definitions like tool data, work objects and so on along with some event routines

and help functions are placed in Common.sys and CommonCell / CommonSC3000

/ CommonSC6000.

Application code vs FlexLoader Vision code

FlexLoader RAPID code has RAPID system code responsible for picking parts

from the feeder. The interface between application code and system code for

picking are so called reference positions.

RefPosIn is a robot position from which picking of parts is possible. After picking

a part, the system code returns the robot to RefPosOut. The application part is

responsible to handle parts, starting from RefPosOut, and handling all RAPID code

until the robot can be returned to RefPosIn.

xx1800002289

Continues on next page

92

Product manual - FlexLoader SC 6000

3HAC051768-001 Revision: D

© Copyright 2014-2020 ABB. All rights reserved.

7 RAPID program

7.2 FlexLoader application functionality

Summary of Contents for FlexLoader SC 6000

Page 1: ...ROBOTICS Product manual FlexLoader SC 6000 ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 78: ...This page is intentionally left blank ...

Page 172: ...This page is intentionally left blank ...

Page 174: ...This page is intentionally left blank ...

Page 176: ...This page is intentionally left blank ...

Page 178: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 186: ...This page is intentionally left blank ...

Page 192: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 283: ......