14.3.2 Load

Overview

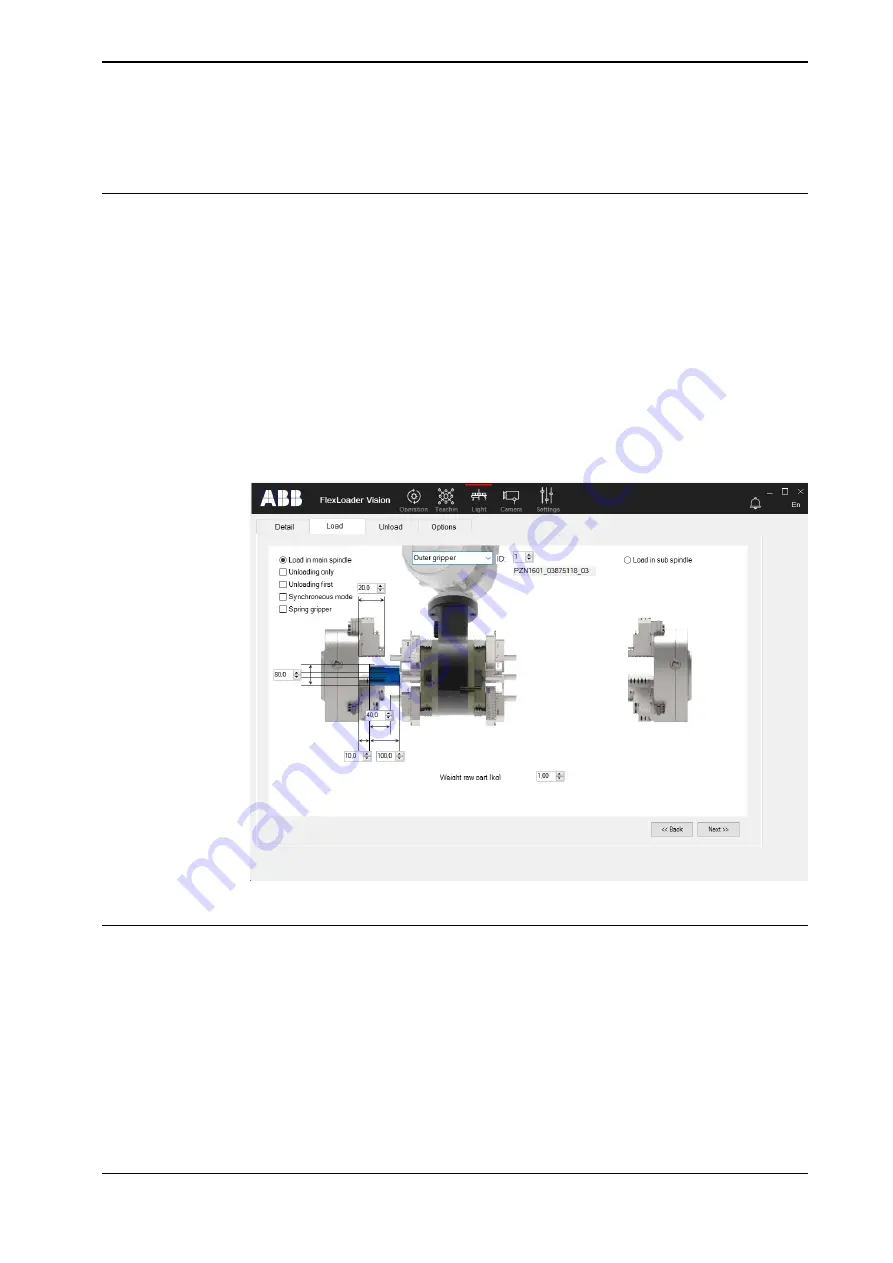

The

Load

tab specifies all the essential dimensions for loading a detail.

•

Diameter and height of the raw material.

•

Grip height for the raw material (TCP for the gripper fingers is assumed to

be at the lower edge of the fingers).

•

The protrusion of the chuck fingers and the insertion depth of the part.

•

Part weight.

In addition, the gripper type is specified (

Outer gripper

/

Inner gripper

) as well as

the ID number of the gripper fingers. If desired you can choose to load in the

sub-spindle.

If enabled by the integrator, activation codes for user-defined sequences can be

sent to the robot.

xx1800000275

Normal loading procedure

Normally, the new raw material is loaded first and the finished detail is unloaded

later:

1 The robot retrieves the detail on the camera belt.

2 The robot loads the new detail in the machine.

3 The robot retrieves the finished detail in the machine with its empty gripper.

4 The robot exits the machine, performs any activated options and leaves the

finished detail on the outconveyor.

Continues on next page

Product manual - FlexLoader Vision

227

3HAC051771-001 Revision: B

© Copyright 2014-2018 ABB. All rights reserved.

14 FlexLoader Vision Lite

14.3.2 Load

Summary of Contents for FlexLoader Vision

Page 1: ...ROBOTICS Product manual FlexLoader Vision ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 14: ...This page is intentionally left blank ...

Page 16: ...This page is intentionally left blank ...

Page 62: ...This page is intentionally left blank ...

Page 96: ...This page is intentionally left blank ...

Page 180: ...This page is intentionally left blank ...

Page 218: ...This page is intentionally left blank ...

Page 286: ......

Page 287: ......