7.5 Driving belt (tension check, adjustment and replacement)

Inspection

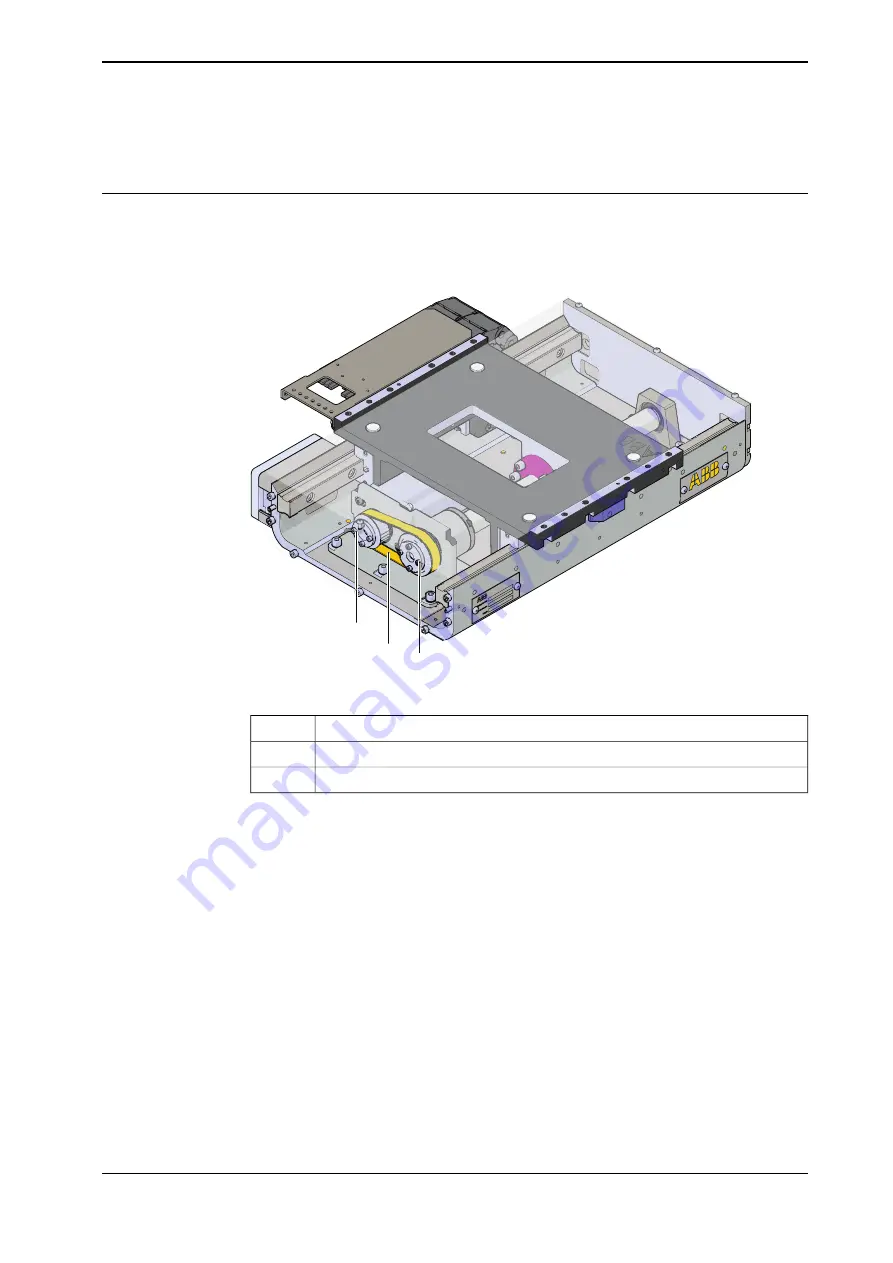

To inspect the driving belt of an horizontal axis, remove the upper cover.

To inspect the belt of a vertical axis, it is necessary to remove the axis from the

horizontal axis or surface place to which it is attached.

C

C

B

B

A

A

xx1800002168

Motor shaft pulley

A

Driving belt

B

Ballscrew shaft pulley

C

Continues on next page

Product manual - FlexPLP IRPLP 220

119

3HAW050041018-001 Revision: C

© Copyright 2016 - 2018 ABB. All rights reserved.

7 Maintenance

7.5 Driving belt (tension check, adjustment and replacement)

Summary of Contents for FlexPLP IRPLP 220

Page 1: ...ROBOTICS Product manual FlexPLP IRPLP 220 ...

Page 12: ...This page is intentionally left blank ...

Page 32: ...This page is intentionally left blank ...

Page 50: ...This page is intentionally left blank ...

Page 56: ...This page is intentionally left blank ...

Page 82: ...This page is intentionally left blank ...

Page 112: ...This page is intentionally left blank ...

Page 126: ...This page is intentionally left blank ...

Page 130: ...This page is intentionally left blank ...

Page 136: ...This page is intentionally left blank ...

Page 144: ......

Page 145: ......