3.5.4 Emergency stop and stroke limit system

General

It is recommended to ensure the emergency stop and stroke limit system

effectiveness every month.

Motor brake

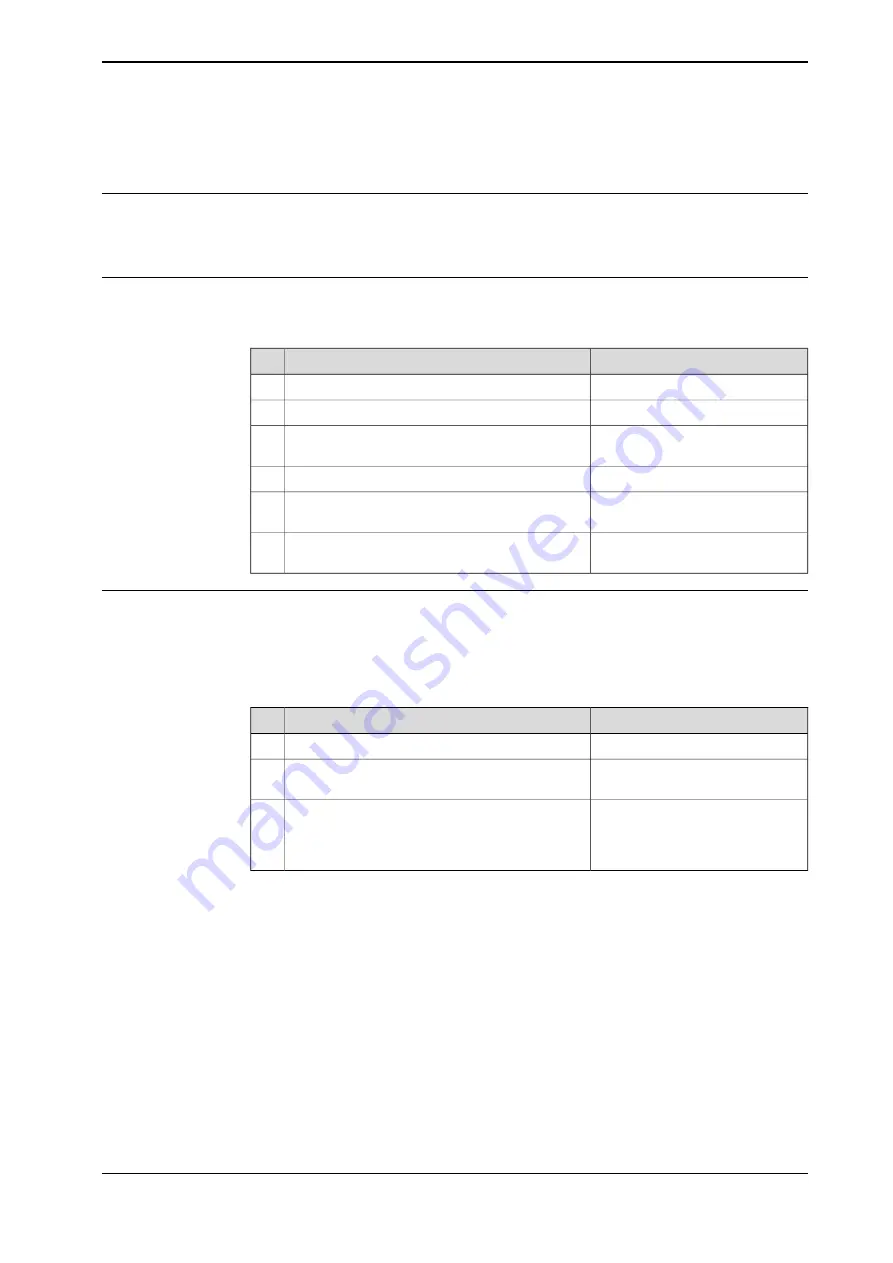

The procedure below details how to ensure the effectiveness of the motor brake

in case of emergency stop.

Note/Illustration

Action

The FlexTrack is powered, but not moving.

1

Press the emergency stop button.

2

The brake is applied; you should hear the noise

in the motor area.

3

Try to push the carriage manually.

4

If the brake is correctly applied, it is not possible

to move the carriage manually.

5

Proceed with the required validations in the con-

trol system to switch back to auto mode.

6

Verification of the effectiveness of the stroke limit system

A software limit prevents the carriage from moving beyond its acceptable upper

and lower stroke limits.

The procedure below details how to ensure the software stroke limit is working

correctly:

Note/Illustration

Action

Switch the IRC5 to manual mode.

1

With the teach pendant, try to jog the carriage to

both ends.

2

If the software limits are functional, it should not

be possible to go beyond the defined upper or

lower end position, and it should not be possible

to reach the hard stops.

3

Product manual - FlexTrack IRT501-66/66R/90/90R

135

3HAW050008590-001 Revision: C

© Copyright 20042018 ABB. All rights reserved.

3 Maintenance

3.5.4 Emergency stop and stroke limit system

Summary of Contents for FlexTrack IRT501 Series

Page 1: ...ROBOTICS Product manual FlexTrack IRT501 66 66R 90 90R ...

Page 8: ...This page is intentionally left blank ...

Page 38: ...This page is intentionally left blank ...

Page 118: ...This page is intentionally left blank ...

Page 174: ...This page is intentionally left blank ...

Page 178: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 186: ...This page is intentionally left blank ...

Page 198: ...This page is intentionally left blank ...

Page 200: ...This page is intentionally left blank ...

Page 202: ......

Page 203: ......