While every effort has been taken to ensure the accuracy of information contained in this book and any associated promotional and information material

JOKAB SAFETY cannot accept responsibility for errors or omissions and reserves the right to make any improvements without notice. It is the users

responsibility to ensure that this equipment is correctly designed, specified, installed, cared for and operated to meet all applicable local, national and

international codes/regulations. Technical data in our book is correct to the level of accuracy of Jokab Safety´s test procedures as verified by various

international approved bodies. Other information (such as application examples, wiring diagrams, operation or use) is intended solely to illustrate the

various uses of our products. JOKAB SAFETY does not quarantee or imply that the product when used in accordance with such examples in a parti-

cular environment will fulfil any particular safety requirement and does not assume any responsibility or liability for actual use of the product based on

the examples given.

2TLC172243M9801, rev A

ABB AB/Jokab Safety

Varlabergsvägen 11

S-434 39 Kungsbacka

Sverige

ABB AB/Jokab Safety

Boplatsgatan 3

S-213 76 Malmö

Sverige

ABB AB/Jokab Safety

Mekanikervägen 6

S-564 35 Bankeryd

Sverige

ABB AB/Jokab Safety

Kanalvägen 17

S-183 30 Täby

Sverige

ABB AB/Jokab Safety

Fältmätargatan 16

S-721 35 Västerås

Sverige

Technical data

Manufacturer

Address

ABB AB / JOKAB SAFETY

Varlabergsvägen 11

SE-434 39 Kungsbacka

Sweden

Article number /

ordering data

Fox21:

2TLJ020160R2100

Fox22:

2TLJ020160R2200

Fox31:

2TLJ020160R0100

Fox32:

2TLJ020160R0200

Power supply

Rated insulating voltage

Ui

690V

Switching capacity AC-15

220.. 240V, 6A

380…440V, 4A

500V, 3A

Connection cable cross

sections single resp.

multi-strand

1-4 mm

2

Fine wire with core end

bush

(DIN 46228)

0.75-2.5 mm

2

Terminal screws

M4

Short circuit protection,

fusible cut-out (gL)

25A max.

Insulation requirements

met up to

480V~

Cable entry

M20

General

Protection class

IP65

Ambient temperature

Operation: -

15…+60

°C

Material:

Safety cover

Pedal

Aluminium

Shockproof thermoplastic

Size

See drawing

Weight (approx..) with

safety cover

Fox31: 1.7 kg

Fox32: 3 kg

Colour

Yellow and black

Mechanical life

Number of operations

Position 2: 1x10

6

Position 3: 3 x 10

5

Safety / Harmonized Standards

Conformity

European Machinery Directive 2006/42/EC

EN ISO 12100:2010,

EN 60204-1:2006+A1:2009,

EN ISO 13849-1:2008,

EN 60947-5-1:2003+A1:2009

EN ISO 13849-1

Performance level: Up to PL c, category 1

B

10d

: 300 000

Certificates

BG

EC Declaration of conformity

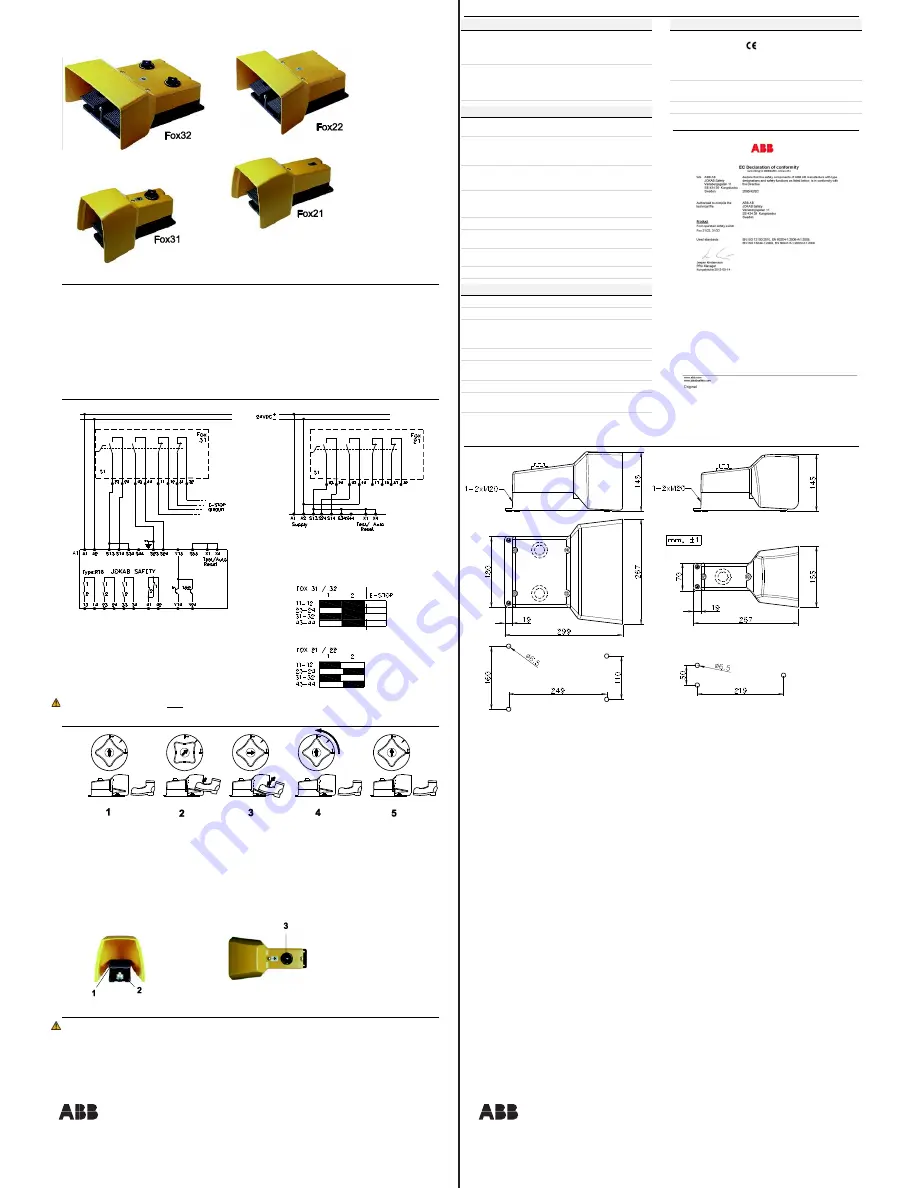

Dimensions

Fox21/31

Fox32/22

Original instructions

Fox

–

Safety foot operated switch

General description

The foot-operated safety switch Fox have been developed for industrial application with high mechanical and electrical

endurance. The foot-operated switches are used on wood processing machines, CNC machines, building machines and

bending machines. Normally a safety foot operated switch is used when the operator has to have both hands free.

Fox is available with a three or two positioning function in single and double pedal variants. Fox is always supplied with

duplicated contacts and robust safety cover.

Fox 31/32, three position function,

provide stop signals in the top and bottom position. Start/ready signals for separate

starting are provided in a distinct middle position. After a stop in the bottom position a start or clear signal cannot be given

before the reset knob has been operated and the pedal has been pushed into its middle position.

Fox 21/22, two-position function

, provide stop signal in the top or pedal released position. A start/ready signal for

separate starting is given in the bottom or fully depressed position.

Connection example

–

Fox

Warning!

All the safety functions

must

be tested before starting up the system.

System description

–

three position pedal Fox 31/32

1) Normal: In resting position, the machine is OFF and the operator is preparing the work piece.

2) Operation: By pressing the pedal to the middle position the contacts 23-24 and 43-44 are closed and the safety

relay is activated. The machine is running.

3) E-Stop: If danger occurs the operator press the pedal to the third (bottom) position. A stop signal is immediately

sent to the machine. The safety relay falls and the machine stops. NB! Only available on Fox 31 and Fox 32.

4) Reset: After reaching the third position the pedal is locked and must be reset by turning the knob 90° counter

clockwise by hand, thereby releasing the latch.

5) Normal: The pedal is now in its stand-by position again, ready for next operation.

Maintenance

Warning!

The safety functions and the mechanics shall be tested regularly, at least once every year to confirm that all the safety

functions are working properly.

In case of breakdown or damage to the product, contact the nearest ABB/Jokab Safety Service Office or reseller. Do not

try to repair the product yourself since it may accidentally cause permanent damage to the product, impairing the safety of

the device which in turn could lead to serious injury to personnel.

B) Pedal Fox21 with safety module RT9

A) Pedal Fox31 with safety module RT6

Version contact configuration:

1) Pedal

2) Contact point

3) Lockout reset knob