27/36

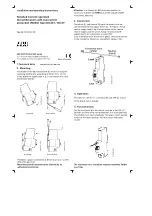

7.2.4. Control Box connection

The connection of the control box with the auxiliary power supply and the signal cables must be carried out in

accordance with the electrical diagram applicable to the project. The terminal block in the control box is labelled

with the corresponding indications.

The cable supply to the control box must be designed with screened cables, screening earthed at one side

and separated cables for signal and voltage supply.

The supply of the heating resistance should be operated permanently regardless of the season and climate, and

only interrupted for maintenance work.

7.3. Commissioning

7.3.1. Status Check

The following checks must be performed before commissioning:

•

Perfect condition of the insulators

•

Apparatus is in the OFF position

•

Check the compliance between the specifications for the supply voltage on the rating plate and the

installation or system

•

Presence of the manual tripping crank

•

Correctly performed earthing

•

Apparatus has reached ambient temperature (

±

5°C)

•

The heating resistances of the control box and pole are connected and in operation.

•

No traces of moisture and water in the control box

•

With the power supply disconnected, check the fixation of the control-connection terminals in the drive

unit and control box

Option

: Before switching on the power supply:

•

If equipped with a capacitor fast discharge, this must be deactivated. For this, set the switch to the

“Operation or service“ position

•

If equipped with a low-voltage circuit-breaker for the control circuit, to the latter must be switched on

7.3.2. Commissioning

The following steps are to be performed for commissioning:

•

Switch on the power supply and wait until the READY indicator lamp lights up continuously (approx. 1-3

minutes), = charging of the capacitors

•

To check the OFF position, switch off the apparatus with the local Off push button

•

Switch the apparatus on with the local On push button or by remote signals

•

In both positions, check that the remote signalling matches the mechanical local display

•

If equipped with a LOCAL/REMOTE/GLOBAL selector switch, check both operating modes and in each

case, operate with the relevant commands and check the ON/OFF status indications

•

Repeat the switching cycles several times, locally

and

remote controlled, read off the switch counter

and note the value in the apparatus logbook

•

The apparatus is ready for remote control operation

7.3.3. Function of the Ready Signal

As long as the LED indicator “Ready“ is not active

or

the signal contact “READY“ is not closed, the

apparatus cannot be electrically actuated.

The LED indicator “Ready“ and the contact “READY“ indicate the following conditions:

•

Controller (CPU) in standby, ready for operation

•

Monitoring whether the apparatus (1-pole or 2-pole) is in the defined open or closed position

•

Capacitor charge is sufficient to perform the switching action O-CO

•

Coil supervision

If all criteria are satisfied, the apparatus can be operated. If one of the above criteria is not fullfilled the apparatus

goes into the “NOT READY” state.

Summary of Contents for FSK II S +

Page 2: ...2 36 ...