14

ABB Power Distribution

6

Commissioning/Operation

6.1

Note on safety at work

• The switchgear may only be operated by

specially trained personnel who are familiar with

the characteristics of the particular device.

• Observe the relevant instructions in section 1.2.

6.2

Preparatory activities

(Prior to application of primary voltage)

• Check the circuit-breaker for damage and

restore to the proper conditions where

necessary.

• Remove any contamination (particularly on the

insulating materials) which has occurred during

transit, storage or installation.

• Check the primary and secondary connections

and the protectiv conductor terminal.

• Check the charging motor on circuit-breakers

with motor-operated mechnisms by applying

auxiliary voltage. The stored energy spring is

charged.

• On breakers with manual charging mechanisms,

charge the stored energy spring by hand (see

Section 6.3.1).

• Perform a trial opening or closing operation of

the circuit-breaker using push-button 54.2 or

54.3 (taking into account any required auxiliary

voltage and any relevant interlocks). Observe

switch position indicator 55.4 and charging

condition indicator 55.8.

• Remove transport plugs 57.5 from the poles.

• Check that pole tube caps 57.4 are properly

fitted.

• Ensure that the Instruction Manual is available to

the operators at all times.

6.3

Operation of the circuit-breaker

(Figures 3/3 and 6/1)

6.3.1

Charging the spring energy storage mechanism

Circuit-breakers with charging motors:

• Charging takes place automatically.

• If the charging motor breaks down, the charging

process can be carried out or completed

manually.

Circuit-breakers with manual charging mechanisms:

• Insert charging lever 128 into locating socket

55.6 and pump up and down for approx. 25

strokes until the charged condition is displayed.

• When the charged condition is reached, the

charging mechanism automatically disengages,

and further strokes of the charging lever have no

effect.

5

Installation

Careful and professional installation of the

switchgear is one of the fundamental conditions of

trouble-free circuit-breaker operation.

• Remove handling unit TE and lifting lugs T if

fitted (Figure 2/2).

• Install the breaker housing in the panel without

tension or distorsion. The brackets of handling

unit TE can also be used to fasten the breaker to

the switchroom floor.

• Connect the main terminals without any perma-

nent tension or pressure forces, exerted for

example by the conductor bars.

• When connecting the conductor bars, the bolts

must be inserted to the depth shown on the

dimensional drawing.

• Take account of any tested terminal zone.

• Use DIN bolts of tensile class 8.8, fastening

conductor bars together with dished washers.

• Make a short-circuit proof connection between

the PE conductor and the main earthing bar in

the switchgear, using contact washers.

• Remove any dirt. See also section 7.3.1.

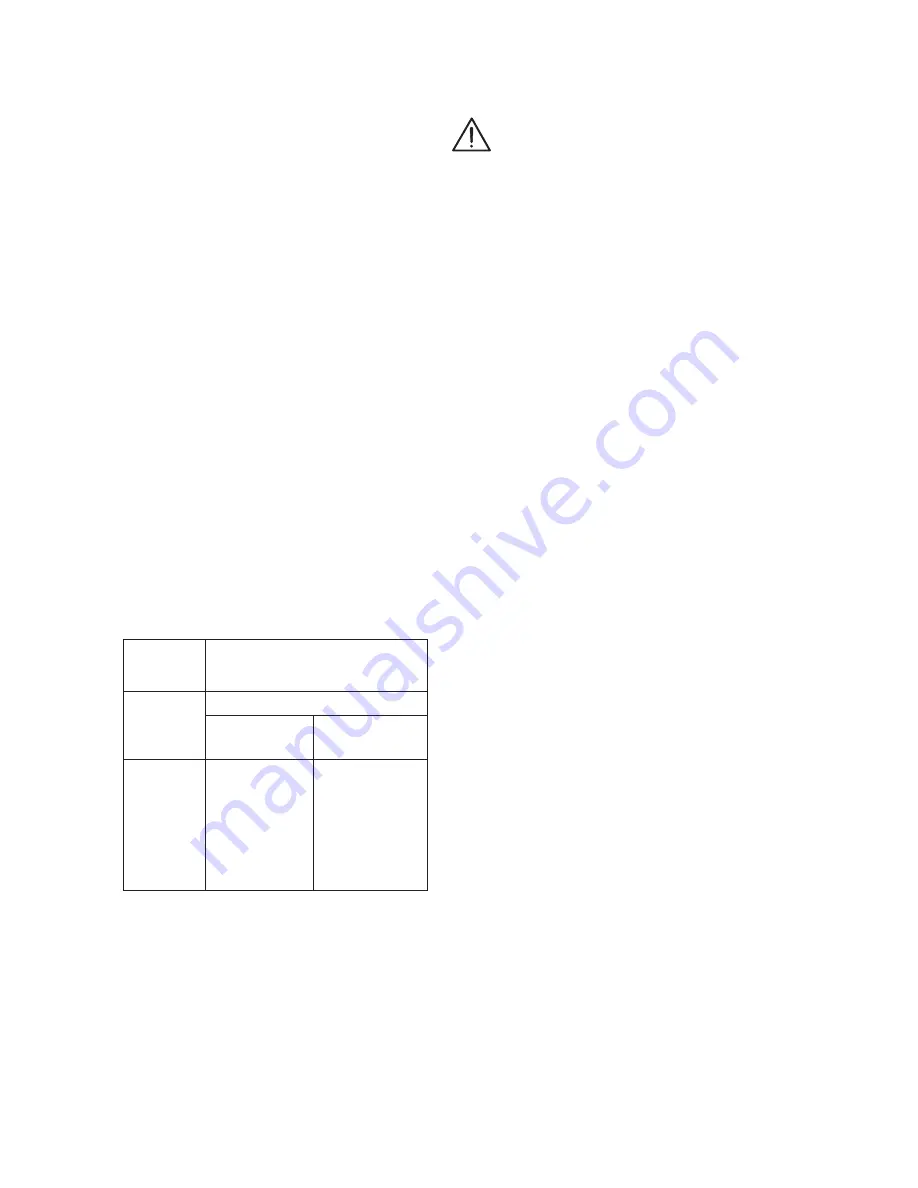

Recommended

rated tightening torque

1) 2)

Nm

Lubricant

3)

Thread size

without

Oil

or grease

M 6

10.5

4.5

M 8

26

10

M 10

50

20

M 12

86

40

M 16

200

80

1)

Rated tightening torques for fasteners without lubrication are

based on the thread friction coefficient 0.14 (the actual

values of which are subject to unavoidable, in some cases

not insignificant, spread)

2)

Rated tightening torques for fastener with lubrication in

accordance with DIN 43 673.

3)

Thread and contact face of head lubricated

Take account of any tightening torques which deviate from the

general table (e.g. for contact systems or device terminals) as

stated in the detailed technical documentation.

It is recommended that the threads or head contact surfaces of

the bolts be lightly oiled or greased, so as to achieve a precisely

defined rated tightening torque