Power Break® II Devices

Draw-Out Device Installation

—

Table 4. Illustration of the rejection-scheme logic, showing which switches may be

installed in which substructures.

Rejection

Feature

Draw-Out

Position

Indicator

—

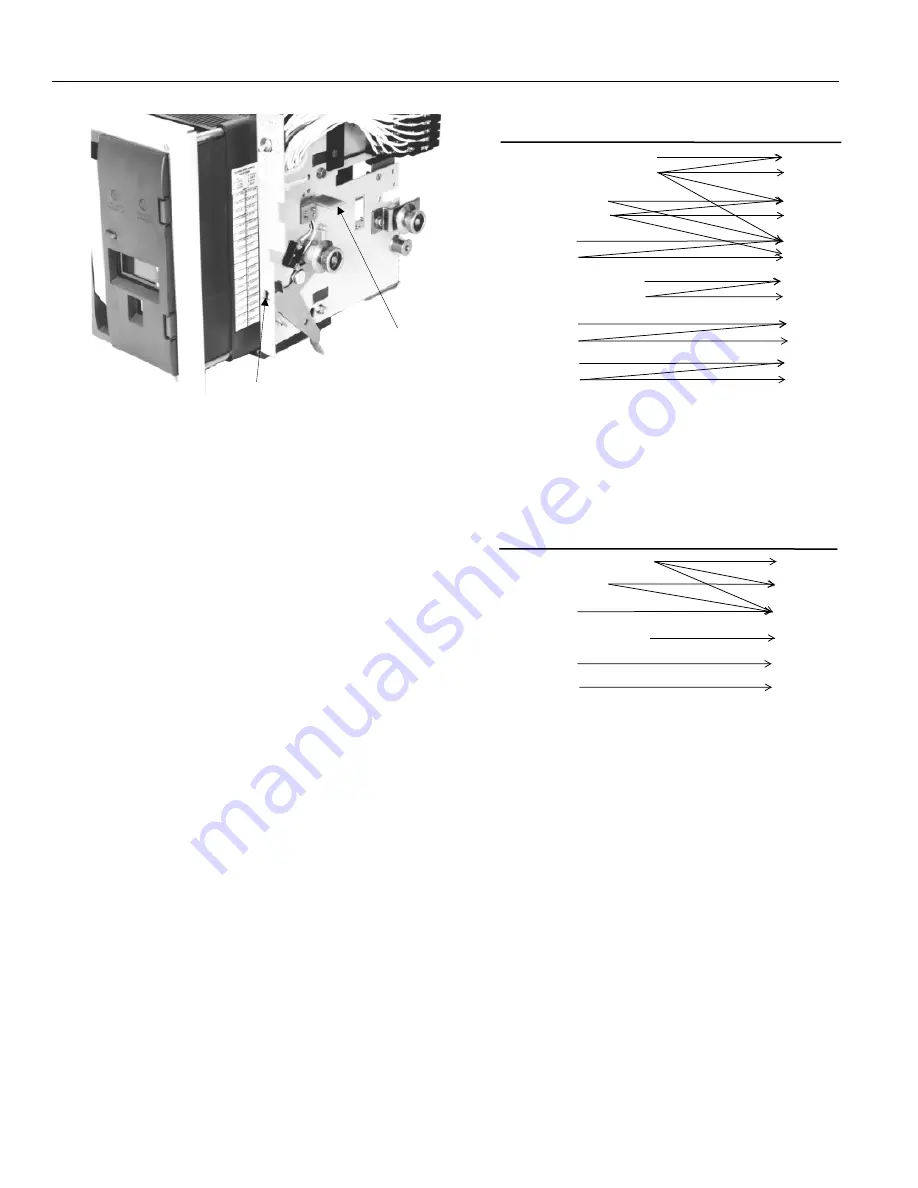

Figure 3. Right side of the device, showing the rejection feature, draw-out position indicator, and

electric operator cutoff switch.

Draw-Out Position Indicator. Indicates whether the device is

in the connected, test, or disconnect position.

Electric Operator Cutoff Switch. Prevents cycling of the

spring-charging motor during installation or removal of a

device.

Draw-Out Interlock. This feature trips a closed device if the

wrench interlock is deliberately defeated. The device is

tripped before the primary disconnects part as the device is

racked out and before the primary disconnects engage as the

device is racked in.

Rejection Feature. This feature prevents insertion of a device

into a substructure of lower ampere rating or higher short-

circuit rating. It does not reject a device with incompatible

control wiring. See the label on the device or Tables 1 or 2 for

the proper substructure catalog number. (Also shown in

Figure 8.)

Tables 3 and 4 illustrate the rejection scheme logic. Note that

devices may be safely used in higher-rated substructures.

However, local and industry codes and standards require that

conductors be sized to the substructure. Therefore, installing

devices in substructures with higher ratings is possible, but

not economical.

Draw-Out Padlock Accessory. When a padlock is installed, this

feature works with the racking shaft lockout plate to prevent

engagement of the racking shaft wrench.

Shutter Actuator. A stud actuates the optional shutter

accessory.

By-Pass Switch Actuator. Operates the optional by-pass

switch accessory.

Lifting Bar. The Lifting Bar, catalog number TDOLB, is

available for safe handling of the draw-out device, as

illustrated in Figures 4 and 5.

Note: In the circuit breaker catalog number, replace “X” with "G" for

EntelliGuard ® Trip unit or “B” for MicroVersaTrip Plus™ or MicroVersaTrip

PM™ Trip Units or with “D” for Power+™ Trip Units

—

Table 3. Illustration of the rejection-scheme logic, showing which circuit breakers may

be installed in which substructures.

Note: In the switch catalog number, replace “X” with "W"

for EntelliGuard ®

Control

U

nit

s

or with

“

Y

” for Power+™

Control

Unit

s

SPSDOS08

SPSDOS16

SPSDOS20

SPSDOS25

SPSDOS30

SPSDOS40

SSD08X

SSD08X

202, X204, X208

SSD16X

210, X216

SSD20X

220

SSD25X

210, X220, X325

SSD30X

330

SSD40X

440

Substructure

SPSDOS08

SPSDOS16

SPSDOS20

SPSDOS25

SPSDOS30

SPSDOS40

Substructure

Breaker

SSD08X

SSD08X

202, X204

, X208

SHD08X

202, X204, X208

SSD16X

210,X216

SHD16X

210,X216

SSD

20X

2

2

0

SHD

20X

2

2

0

SSD25

X210,X220,X325

SHD25X

210,X220,X325

SSD30X

330

SHD30X

330

SSD40X

440

SHD40X

440

SP

H

DOS08

SP

H

DOS16

SP

H

DOS20

SP

H

DOS25

SP

H

DOS30

SP

H

DOS40

Switch

2