Summary of Contents for GSBK 170

Page 46: ...46 Installation and maintenance guide 1ZSC000563 AAB EN REV 6 2019 09 12 ...

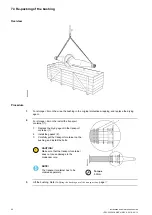

Page 52: ...52 Installation and maintenance guide 1ZSC000563 AAB EN REV 6 2019 09 12 ...

Page 54: ...54 Installation and maintenance guide 1ZSC000563 AAB EN REV 6 2019 09 12 ...

Page 62: ...62 Installation and maintenance guide 1ZSC000563 AAB EN REV 6 2019 09 12 ...

Page 66: ...66 Installation and maintenance guide 1ZSC000563 AAB EN REV 6 2019 09 12 ...

Page 70: ......

Page 71: ......