Schedule

Maintenance

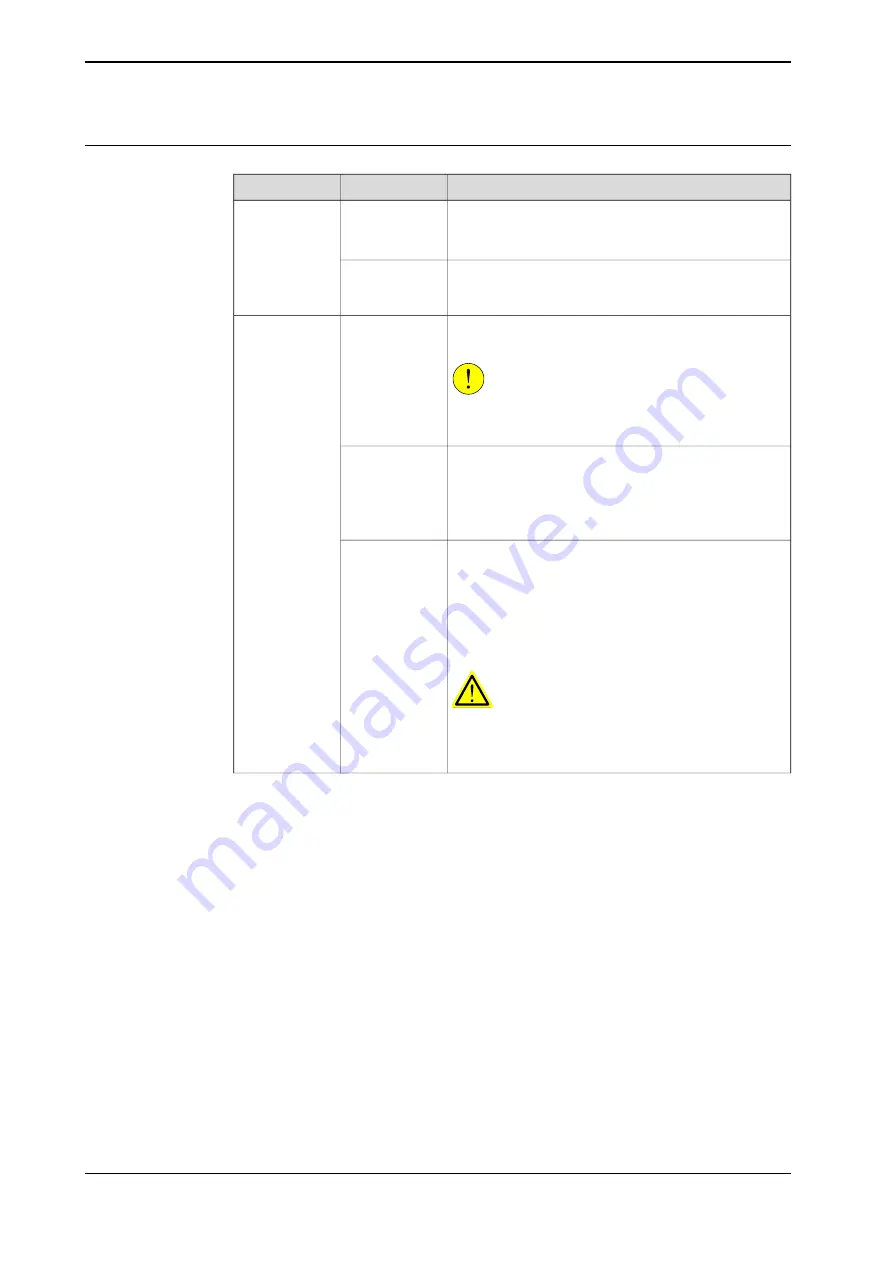

Item

Time interval

Inspect the electrode caps for deformation or wear.

Electrode

caps/Tips

Every day

Make sure that the electrode caps are correctly posi-

tioned in line with each other.

Make sure that that the working space of the welding

gun is clean and free from materials and liquids that

can cause slipping and tripping hazards.

Workplace

Clean the GWT C9 protection cover from welding

splatters with a clean cloth.

CAUTION

Do not use a metallic brush since it can scrape the

painting.

General condi-

tion

Every 250,000

weld strokes

and once a year

Look for premature wearing or damage. Make sure that

the cables are correctly positioned within the harness.

Cables, harness

and connections

Verify that all the communication signals function

properly.

See below drawing, position 41 and 45.

Inspect the condition of the hoses and connectors fit-

tings and make sure that there is no premature wearing

or coolant leaking. Make sure that they are correctly

positioned within the harness and that they can not be

pinched or otherwise damaged.

Water cooling

circuit

If necessary, replace the damaged hoses or fittings.

See below drawing, position 20.

WARNING

Malfunction of the water cooling circuit may cause

severe overheating, and ultimately, the destruction of

the GWT C9!

Continues on next page

66

Product manual - GWT C9

3HAA010198-001 Revision: A

© Copyright 2022 ABB. All rights reserved.

4 Maintenance

4.2 Maintenance planning

Continued

Summary of Contents for GWT C9

Page 1: ...ROBOTICS Product manual GWT C9 ...

Page 62: ...This page is intentionally left blank ...

Page 124: ...This page is intentionally left blank ...

Page 126: ......

Page 127: ......