19

7. Installation

7.1 General information

Correct installation is of primary importance.

The manufacturer’s instructions must be

carefully studied and followed. It is good

practice to use gloves for handling the com-

ponents during installation.

All the operations required for installation,

putting into service, service and mainte-

nance must be carried out by qualified per-

sonnel.

7.2 Normal installation conditions

Maximum ambient air temperature

+ 40 °C

Minimum ambient air temperature

– 5 °C

Relative humidity

%

≤

95

Altitude

≤

1000 m

It must be possible to ventilate the installation room.

Comply with the indications in the product standards (IEC

62271-100) if other installation conditions are involved. Please

contact ABB for special installation requirements.

The areas through which power conductors or auxiliary circuit

conductors are routed must be protected against the access of

animals which could lead to damage or disservice.

7.3 Preliminary operations

– Clean the insulating parts with clean dry rags.

– Make sure that the upper and lower terminals are clean and

free of any deformation caused by shocks received during

transport or storage.

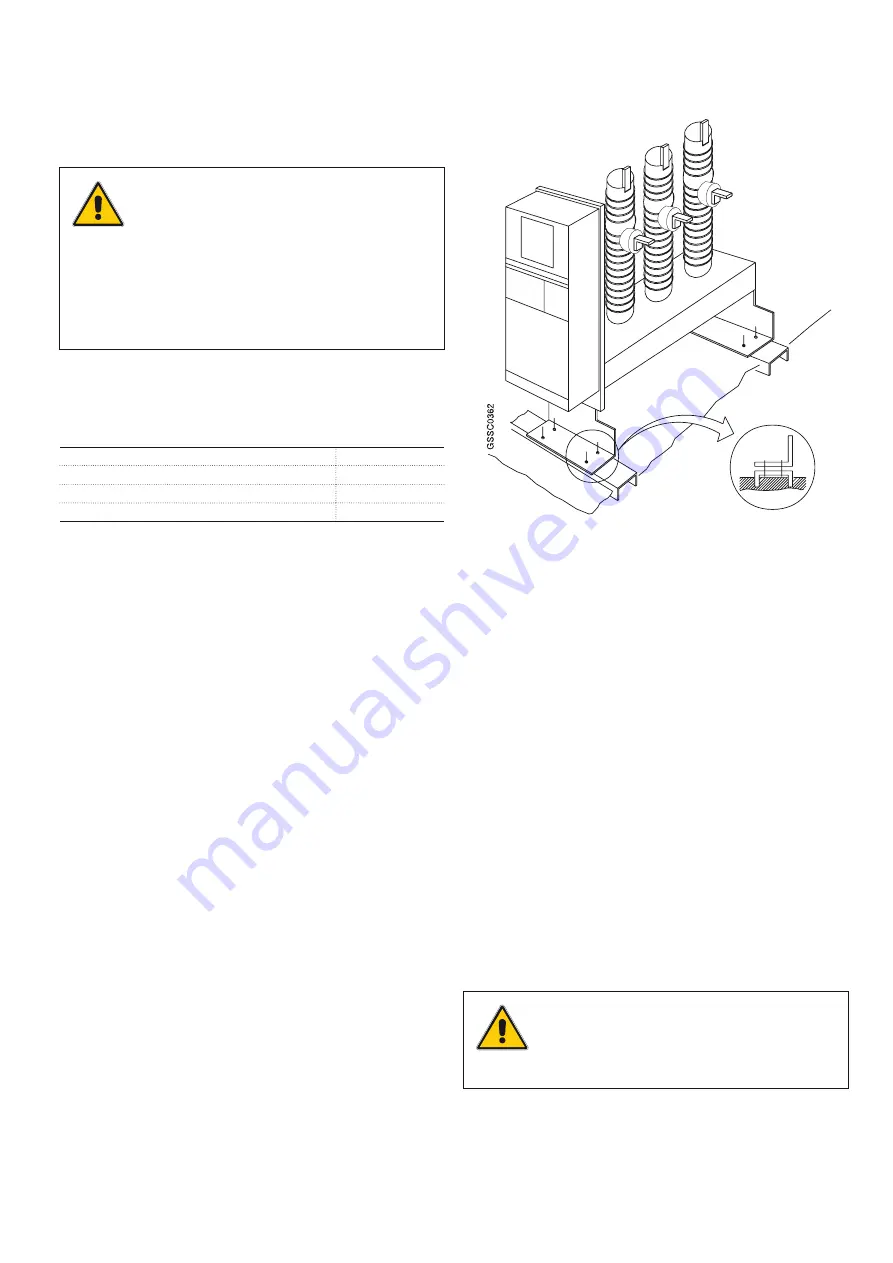

7.4 Installation of fixed circuit-breakers

The circuit-breaker can be installed straight on the floor or on

supporting frames provided by the customer (see fig. 8).

The areas on which the supporting frames or truck (if provided)

rest must be on the same plane to avoid any risk of distortion

in the breaker structure.

A minimum degree of protection (IP2X) must be guaranteed

from the front towards live parts.

The apparatus can be fixed in the following ways:

– by means of special expansion anchoring bolts with M8

threaded hole if the apparatus is fixed to a cement floor

– by means of M8 bolts if the apparatus is fixed to metal

structures or to cement floors into which special steel sec-

tions have been embedded.

Whatever the method used, the fixing surface must be well-

levelled and all the resting points must be on the same hori-

zontal plane.

7.5 Installation of plug-in circuit-breakers

Plug-in circuit-breakers are designed for use in UniSwitch or

UniAir switchgear. Special assembly operations are not usually

required.

However, consult the documentation of the switchgear in ques-

tion.

7.6 Power circuit connections

7.6.1 General recommendations

– Make sure that the circuit-breaker terminals are clean and

are free from any deformation caused by shocks received

during transport or storage.

– Choose the conductor cross-sections to suit the service

and short-circuit current of the installation.

– Provide suitable supporting insulators near the fixed circuit-

breaker terminals or the monoblocs of the cubicles, sized

according to the electrodynamic stress caused by the

short-circuit current of the installation.

The circuit-breaker terminals are always sil-

ver-plated. To clean them, use only dry rags,

soaked in a suitable solvent if necessary.

NOTE. Never use a file or emery cloth!

Figura 7

Summary of Contents for HD4/R

Page 2: ......

Page 21: ...21 7 9 Overall dimensions 7 9 1 Fixed HD4 R 12 24 kV 630 1250 A TN 7237 Figure 9 ...

Page 22: ...22 7 9 2 Fixed HD4 R 12 24 kV 630 1250 A TN 7234 Figure 10 ...

Page 24: ...24 7 9 4 Plug in HD4 S 12 24 kV 630 1250 A TN 7236 Figure 12 ...

Page 25: ...25 7 9 5 HD4 Uniair 12 24 kV 630 1250 A TN 7235 Figure 13 ...

Page 26: ...26 7 9 6 HD4 Uniair F 12 24 kV 630 A TN 7275 Figure 14 ...

Page 27: ...27 7 9 7 HD4 Uniair 2R 12 24 kV 630 1250 A TN 7274 Figure 15 ...

Page 28: ...28 7 9 8 HD4 Uniair A 12 24 kV 630 1250 A TN 7273 Figure 16 ...

Page 29: ...29 7 9 9 HD4 UniMix F 12 24 kV 630 1250 A TN 7366 Figure 17 ...

Page 30: ...30 7 9 10 HD4 R SEC 12 24 kV 630 800 A 1VCD003536 Figure 18 ...

Page 37: ......