Product selection

Part no: Index

No.

Description

UT 3-1

1

Frame

UT 3-12

2

Nest spring

UT 3-4G

3

Nest

UT 3-10

4

Indentor pivot pin

UT 3-3

5

Indentor

UT 3-5

6

Link

UT 3-11

7

Link pin

UT 3-9

8

Handle pivot pin

UT 3-2

9

Movable handle

UT 3-14

10

Groove pin

UT 3-8

11

Washer

UT 3-13

12

Pawl pin

UT 3-6

13

Pawl

UT 3-7

14

Extension spring

Note: Product must be operated in

accordance with applicable national and local

electrical codes.

Lubricate

5

8

1

2

UT3-4G

5

8

1

2

5

8

1

2

UT3-4G

Figure A

Figure B

Figure C

5

8

1

2

5

8

1

2

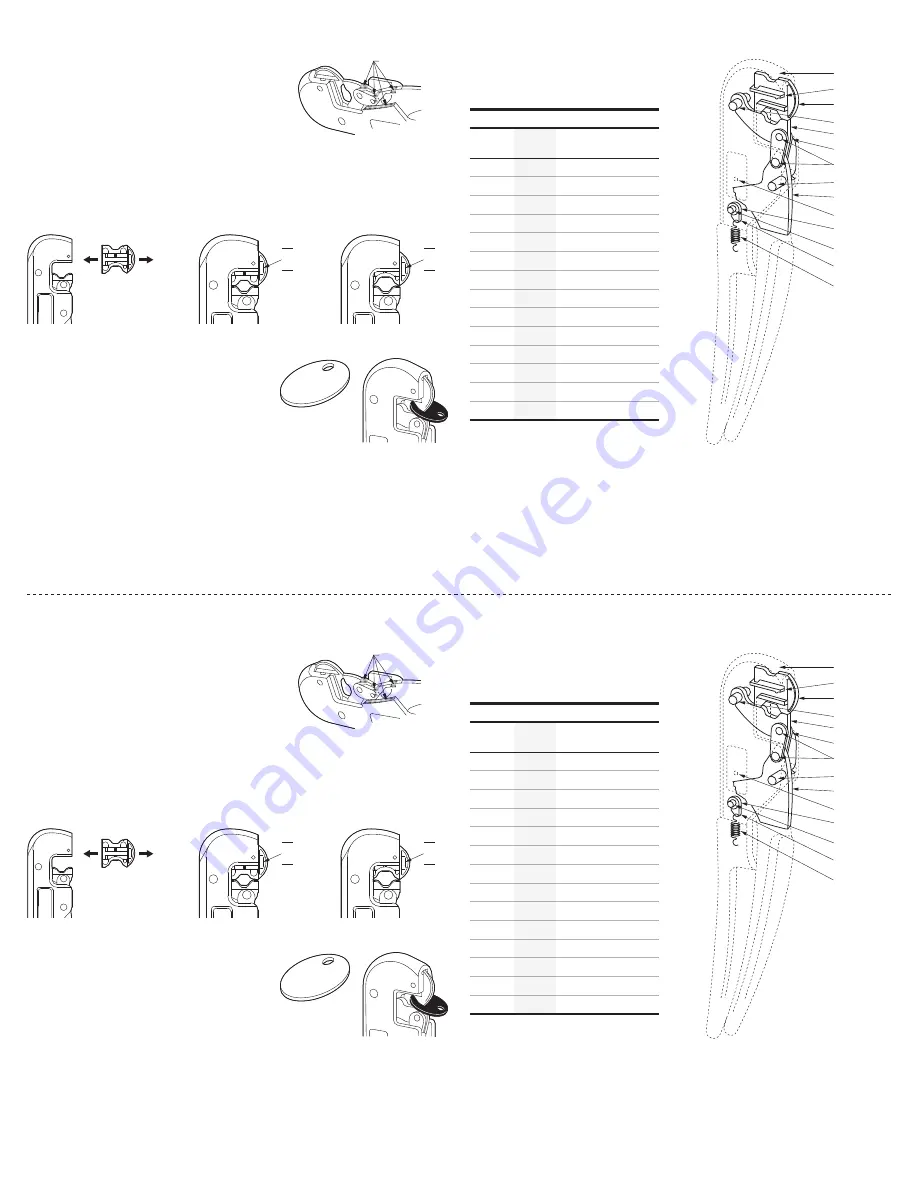

1. Install by inserting

die into tool head.

2. Pull out to remove.

1

2

Tolerance gauge

Figure D

1

Index no.

2

3

4

5

6

7

8

9

10

11

12

13

14

Instructions

Lubrication:

The tool should be oiled occasionally with a

good grade of lubricating oil in the pivot and

link pin areas.

Instructions

Lubrication:

The tool should be oiled occasionally with a

good grade of lubricating oil in the pivot and

link pin areas.

Installing dies:

This tool installs all 1/2" and 5/8" compression connectors. Install both sizes quickly by

removing and reversing the upper die for either size. To install the 1/2" sizes, the die

should be in the position shown in Figure B (1/2" is readable, the 5/8" is upside down). To

install 5/8" sizes, pull the upper die straight out of the tool, reverse the die and re-insert

into tool. The 5/8" is now readable as shown in Figure C.

Installing dies:

This tool installs all 1/2" and 5/8" compression connectors. Install both sizes quickly by

removing and reversing the upper die for either size. To install the 1/2" sizes, the die

should be in the position shawn in Figure B (1/2" is readable, the 5/8" is upside down). To

install 5/8" sizes, pull the upper die straight out of the tool, reverse the die and

re-insert into tool. The 5/8" is now readable as shown in Figure C.

Tool compression test:

To test for proper compression, place the

"tolerance gauge" between the dies and close

the tool. If the gauge is not held in place, the

tool is below tolerance and should be returned

to the factory for repair, Figure D.

Tool compression test:

To test for proper compression, place the

"tolerance gauge" between the dies and close

the tool. If the gauge is not held in place, the

tool is below tolerance and should be returned

to the factory for repair, Figure D.

Part list

Overall dimensions: 12" x 2 1/2" x 3/4"

Weight: 2 lbs. 3 oz.

Part list

Overall dimensions: 12" x 2 1/2" x 3/4"

Weight: 2 lbs. 3 oz.

Product selection

Part no: Index

No.

Description

UT 3-1

1

Frame

UT 3-12

2

Nest spring

UT 3-4G

3

Nest

UT 3-10

4

Indentor pivot pin

UT 3-3

5

Indentor

UT 3-5

6

Link

UT 3-11

7

Link pin

UT 3-9

8

Handle pivot pin

UT 3-2

9

Movable handle

UT 3-14

10

Groove pin

UT 3-8

11

Washer

UT 3-13

12

Pawl pin

UT 3-6

13

Pawl

UT 3-7

14

Extension spring

Note: Product must be operated in

accordance with applicable national and local

electrical codes.

Lubricate

5

8

1

2

UT3-4G

5

8

1

2

5

8

1

2

UT3-4G

Figure A

Figure B

Figure C

5

8

1

2

5

8

1

2

1. Install by inserting

die into tool head.

2. Pull out to remove.

1

2

Tolerance gauge

Figure D

1

Index no.

2

3

4

5

6

7

8

9

10

11

12

13

14

Ins

talling t

ool, UT 3 | Opera

ting Ins

truc

tions | 1

02_R5 | 0014639 B

Ins

talling t

ool, UT 3 | Opera

ting Ins

truc

tions | 1

02_R5 | 0014639 B

—

tnb.abb.com (US/Latin America)

tnb.ca.abb.com (Canada)

abb.com

Warranty: tnb.abb.com/toolregistration

—

tnb.abb.com (US/Latin America)

tnb.ca.abb.com (Canada)

abb.com

Warranty: tnb.abb.com/toolregistration

—

We reserve the right to make technical

changes or modify the contents of this docu-

ment without prior notice. With regard to

purchase orders, the agreed particulars shall

prevail. ABB does not accept any responsibil-

ity whatsoever for potential errors or possible

lack of information in this document.

We reserve all rights in this document and in

the subject matter and illustrations contained

therein. Any reproduction – in whole or in part

– is forbidden without prior written consent

of ABB. © 2022 ABB Installation Products Inc.

and/or its related companies. All Rights

Reserved.

—

We reserve the right to make technical

changes or modify the contents of this docu-

ment without prior notice. With regard to

purchase orders, the agreed particulars shall

prevail. ABB does not accept any responsibil-

ity whatsoever for potential errors or possible

lack of information in this document.

We reserve all rights in this document and in

the subject matter and illustrations contained

therein. Any reproduction – in whole or in part

– is forbidden without prior written consent

of ABB. © 2022 ABB Installation Products Inc.

and/or its related companies. All Rights

Reserved.

—

For parts or service, contact Tool Service Center at:

Phone: 1-800-284-TOOL (8665)

Webpage:

electrification.us.abb.com/tool-service

—

For parts or service, contact Tool Service Center at:

Phone: 1-800-284-TOOL (8665)

Webpage:

electrification.us.abb.com/tool-service

2 of 2

2 of 2