Reasons for changing the damping device can be oil leaks normally the device does

not need maintenance. Repair of the device must not be carried out. Never operate

the breaker without the damping device as damage to the breaker can occur.

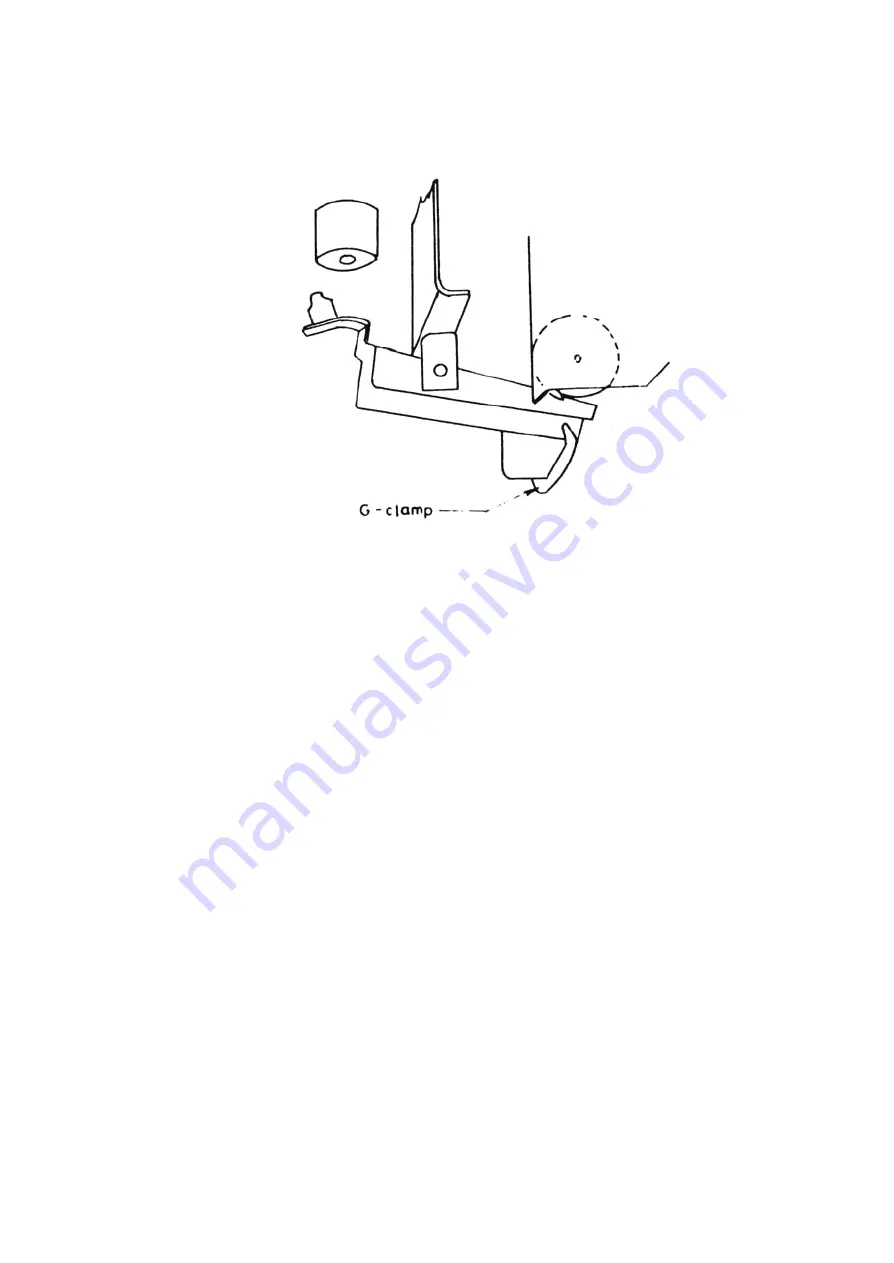

Changing of damping device is carried out as follows:

1. Move the breaker out onto the door.

2. Close the breaker if the damping device is to be changed.

3. Lock and secure the release mechanism according to fig. 14. Be extremely

careful that hands are kept clear of the mechanism and the springs in case of

release.

4. Loosen the devices safety nuts. Withdraw the device from the plate. No other

units need to be loosened. If other units are loosened, there is a risk of the

springs being released. The lower part of the device is pulled out through a

hole in the plate.

5. Insert the new damping device. Adjust it so that at the “ON” position, the step

of the shaft of damping device shall be in line with the damping device

housing.

6. Tighten the safety nuts.

7. Loosen the locking for release mechanism.

1.4.7 Replacement of operating mechanism

1. Remove the breaker from the cubicle and keep it on a suitable foundation.

2. Loosen the operating devices cover, see fig. 15. Lift off cover.

3. Loosen the sliding contacts screws, pin, connecting cables and the 4

screws, see fig.

4. Completely withdraw the operating device.

(22)

Fig - 14

(Locking of the release mechanism for spring)

Summary of Contents for HPA 12kV

Page 7: ...Fig 3b HPA breaker pole for 36 kV ...

Page 9: ... 7 Fig 5 Circuit Breaker ...

Page 13: ...Fig 7A Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 11 ...

Page 14: ...Fig 7B Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 12 ...

Page 15: ...Electrical endurance HPA 13 ...

Page 29: ......