Operation Manual / 4 Product description / A130-M.. - A145-M..

6

Periodic maintenance work

Page 45 / 121

© Copyright 2017 ABB. All rights reserved.

HZTL4031_EN

Revision E

January 2017

6

Periodic maintenance work

6.1

Foreword to maintenance

Maintenance work includes regular visual controls and cleaning operations which are intended

to ensure the trouble-free functioning of the turbocharger.

To allow you to observe the standard service intervals and to maintain a high turbocharger

efficiency, ABB Turbo Systems recommends that the cleaning procedure be carried out during

operation. This allows the thermal load of the engine to be kept low while ensuring maximum

fuel efficiency.

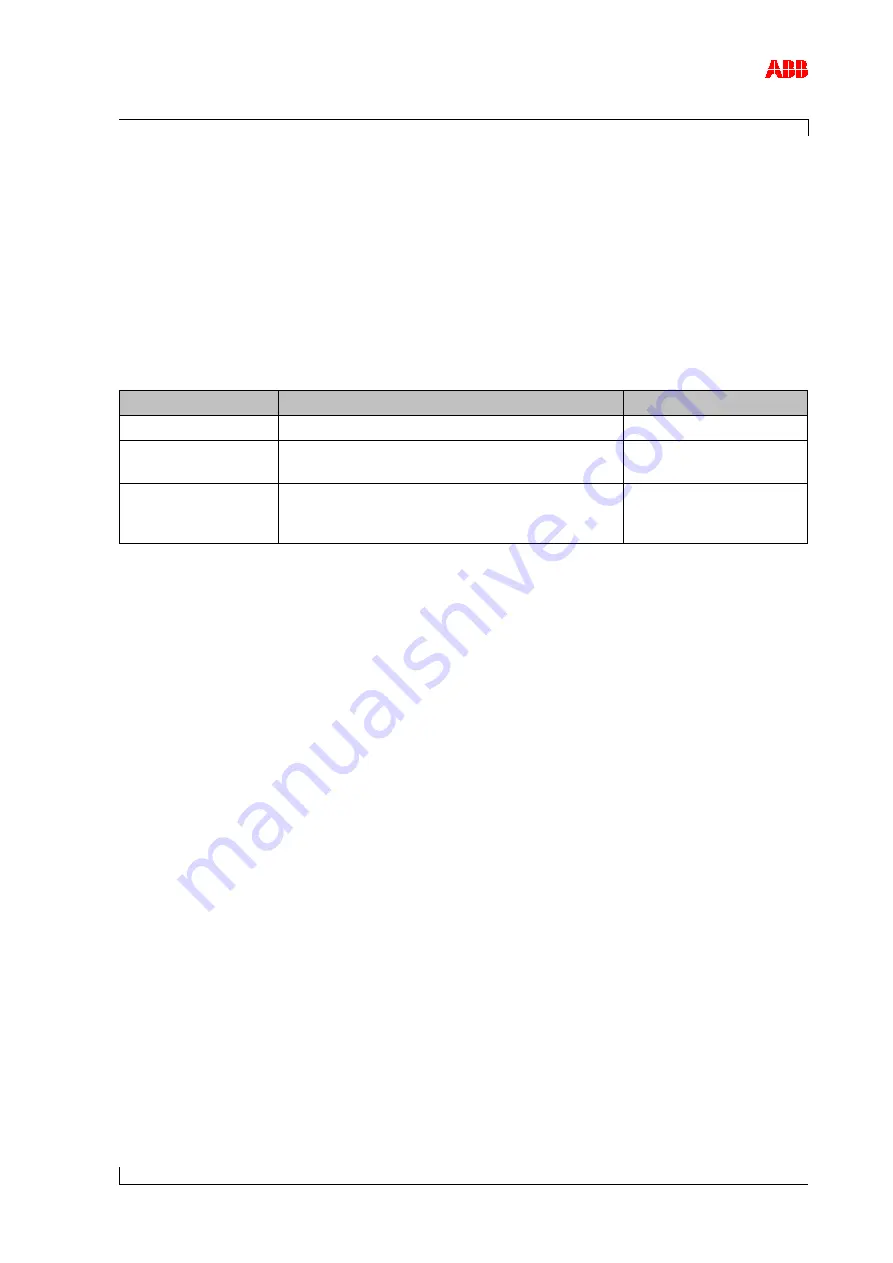

Maintenance interval Maintenance work

Operating status

24 … 72 h

1)

g the compressor during operation [➙

46] Engine load 50 … 85 %

50 … 200 h

1)

Cleaning the turbine during operation [➙

Engine load 20 … 40%

(guideline value)

Similar to the service

interval (usually every

8000 … 12000 h)

2)

Cleaning components mechanically [➙

Engine stopped

Table 11: Maintenance table

[h] = Hours of operation

1)

If the maintenance intervals are incompatible with operation of the engine, contact ABB

Turbo Systems.

2)

ABB Turbo Systems recommends having mechanical cleaning carried out by an ABB

Turbocharging Service Station during the service work. Otherwise, only carry out mechanical

cleaning if cleaning during operation is not sufficient to achieve the thermal load and the rating

of the engine.