Operation Manual / TPL65VA32/33

Troubleshooting

6

Malfunctions during operation

6.3

Page 71

© Copyright 2015 ABB. All rights reserved.

Sept

em

ber

2015

H

ZT

L2464_

EN

R

ev

is

ion

C

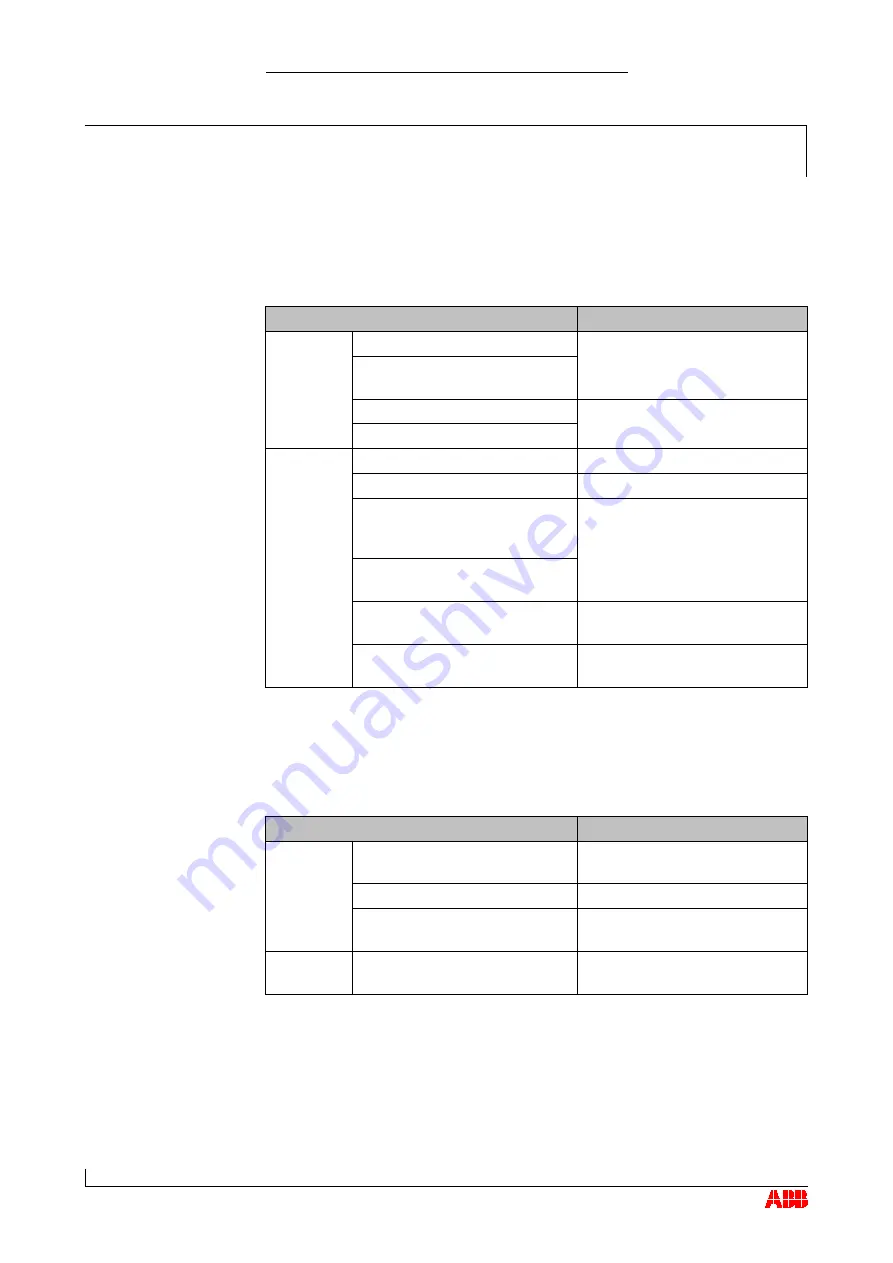

Charge air pressure too low

Engine performance and engine speed unchanged, air intake condition

normal

Possible causes

Elimination

Engine

Air receiver leaking

Make repairs

Gas piping between the engine

and the turbine leaking

Poorly adjusted injection system Correct it

Poorly adjusted valve control

Turbo-

charger

Manometer display wrong

Replace the manometer

Line to manometer leaking

Repair the leak

Contaminated filter silencer

causing excessive loss of

pressure

Clean it

Compressor / turbine

contaminated

Damaged compressor / turbine Contact an ABB Turbocharging

Service Station

Exhaust counterpressure too

high

Clean or repair the boiler or

exhaust silencer

Charge air pressure too high

Engine performance and engine speed unchanged, air intake condition

normal

Possible causes

Elimination

Engine

Malfunctioning injection system Repair it or contact the

manufacturer

Poorly adjusted injection system Correct it

Engine performance higher than

expected

Check engine performance

Turbo-

charger

Manometer display wrong

Replace the manometer