Operation Manual / TPL67-C.. - TPL71-C..

Maintenance

5

Cleaning the compressor during

operation

5.3

Page 61

© Copyright 2017 ABB. All rights reserved.

Febr

ua

ry

2017

HZ

TL2

488_

EN

Rev

is

ion D

Screw in sealing plug (X).

Push the valve activator (Y) against the spring and hold it for 10 ... 15

seconds until the entire volume of water has been injected.

After cleaning, wait at least 5 minutes to allow turbocharger to dry.

NOTICE

If the cleaning operation is not satisfactory, it may be repeated up to

two times.

If the cleaning result is still not satisfactory after three attempts and the

engine values are also unsatisfactory, we recommend that you have the

turbocharger inspected and cleaned by an official ABB Turbocharging

Service Station.

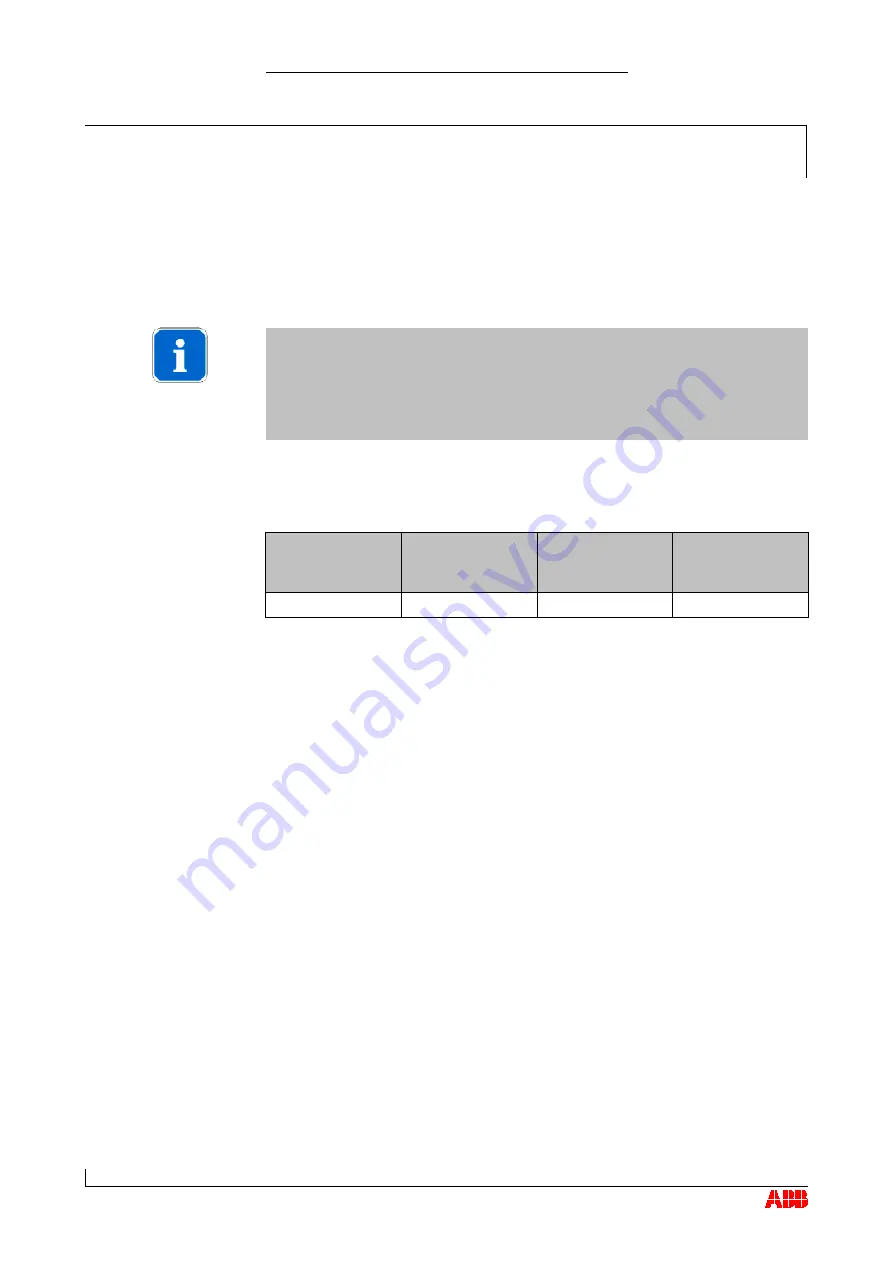

Cleaning parameters per turbocharger compressor

Product

Engine load

Water temperature

[°C]

Contents of water

vessel

[dm

3

]

TPL67-C + 71-C

50 … 85%

5 … 50

0.4 or 1

Surging of the compressor stage

Should repeated surging of the compressor stage occur during compres-

sor cleaning, first the cleaning parameters as well as the engine-side sys-

tem must be checked with regard to deviations (e.g. an increased pres-

sure loss in the charge air cooler) and corrected if necessary.

If, despite correct settings, surging of the compressor stage occurs while

cleaning the compressor, as a remedial measure the engine load can be

reduced further while cleaning the compressor. The reduction of the en-

gine load can lead to a reduction in the effectiveness of the compressor

cleaning.

To avoid reduced engine availability, the cleaning of the compressor

stage at reduced engine load can be carried out during the drying time

following the wet cleaning of the turbine (see section Wet cleaning tur-

bine and nozzle ring during operation).