Operation Manual / TPL65-A32 / -A33 / -A36 + TPL69-A32 / -A33

8 Disassembly and assembly / 8.6 Dismantling and installing the tur-

bine diffuser and nozzle ring

© Copyright 2018 . All rights reserved.

HZTL2498_EN

Revision C

April 2018

u

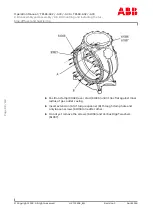

Replace two screws (61056) in the gas outlet casing with two guide

studs (90320) in the upper section of the turbine diffuser (63000).

u

Fit clamps (90921) over the guide studs (90320) and the studs

(61036).

u

To secure the work, screw the nuts (61037) onto the start of stud

threads (61036).

u

Remove the remaining screws (61056) and Verbus Ripp® washers

(61057).

u

Press the turbine diffuser (63000) free using the press-off screws

(90901) and pull it out it until the clamp (90921) is up against the nut

(61037).

u

Loop the lifting gear around the turbine diffuser (63000) and secure it

to a crane.

u

Remove nuts (61037) and clamps (90921).

u

Fully withdraw the turbine diffuser and remove it.

u

Remove the guide studs (90320).

u

Pull nozzle ring (56001) forward and remove.

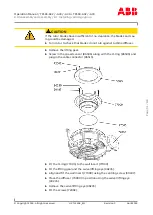

Installing the turbine diffuser and nozzle ring

u

Install the nozzle ring and turbine diffuser in the reverse order of re-

moval.

u

Coat the screw threads with high-temperature grease.

u

Align nozzle ring with holes or cams in gas inlet casing.

Page

89

/

118