Operation Manual / TPL65-A32 / -A33 / -A36 + TPL69-A32 / -A33

8 Disassembly and assembly / 8.8 Dismantling and fitting nozzle ring

at turbine end

© Copyright 2018 . All rights reserved.

HZTL2498_EN

Revision C

April 2018

u

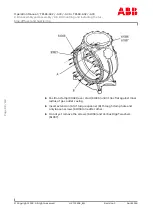

Loosen and remove the remaining screws (61044) and Verbus Ripp®

washers (61043) from the gas inlet casing flange (61001).

u

Pull gas inlet casing complete with nozzle ring just far enough away

from gas outlet casing that nozzle ring (56001) can be lifted away.

u

Loosen the hexagon nuts (90178) on the studs.

u

Fully withdraw the gas inlet casing and remove it.

CAUTION

When setting down the gas inlet casing to one side, use suitable under-

lays and take care not to damage the angles of the insulation.

u

Remove (optional) gasket (61050).

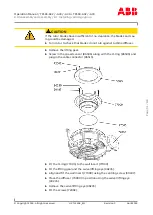

Fitting the nozzle ring

If provided:

u

Insert (optional) gasket (61050) into groove in gas inlet casing

(61001).

u

Align gas inlet casing and secure using hexagon nuts (90178) on studs

(90177) .

u

Insert nozzle ring (56001) and position it.

u

Brush screw threads (61044) with high temperature grease.

u

Fit the gas inlet casing flange to the gas outlet casing using screws

(61044) and Verbus Ripp® washers (61043), then tighten it.

u

Remove the hexagon nuts (90178) from the studs (90177).

u

Replace the studs (90177) with hexagon-head screws (61044) and Ver-

bus Ripp® washers (61043).

u

Remove lifting gear from gas inlet casing (51001).

u

Secure the insulation to the gas inlet casing (51001).

Page

94

/

118