Operation Manual / 4 Product description / TPS44-H.. - TPS52-H..

7 Periodic maintenance work / 7.2 Cleaning components mechanically

© Copyright 2017 ABB. All rights reserved.

HZTL4037_EN

Revision E

July 2017

u

Dispose of dirty water and cleaning agents in accordance with the material safety data

sheet.

7.2.7

Cleaning the cartridge group on turbine end

Soaking the contamination

Baked layers of contamination from fuel residue or coked oil may occur at the turbine end.

The contamination can be removed by soaking and brushing. The procedure for soaking the

layers of contamination as well as for cleaning the turbine are described in the following.

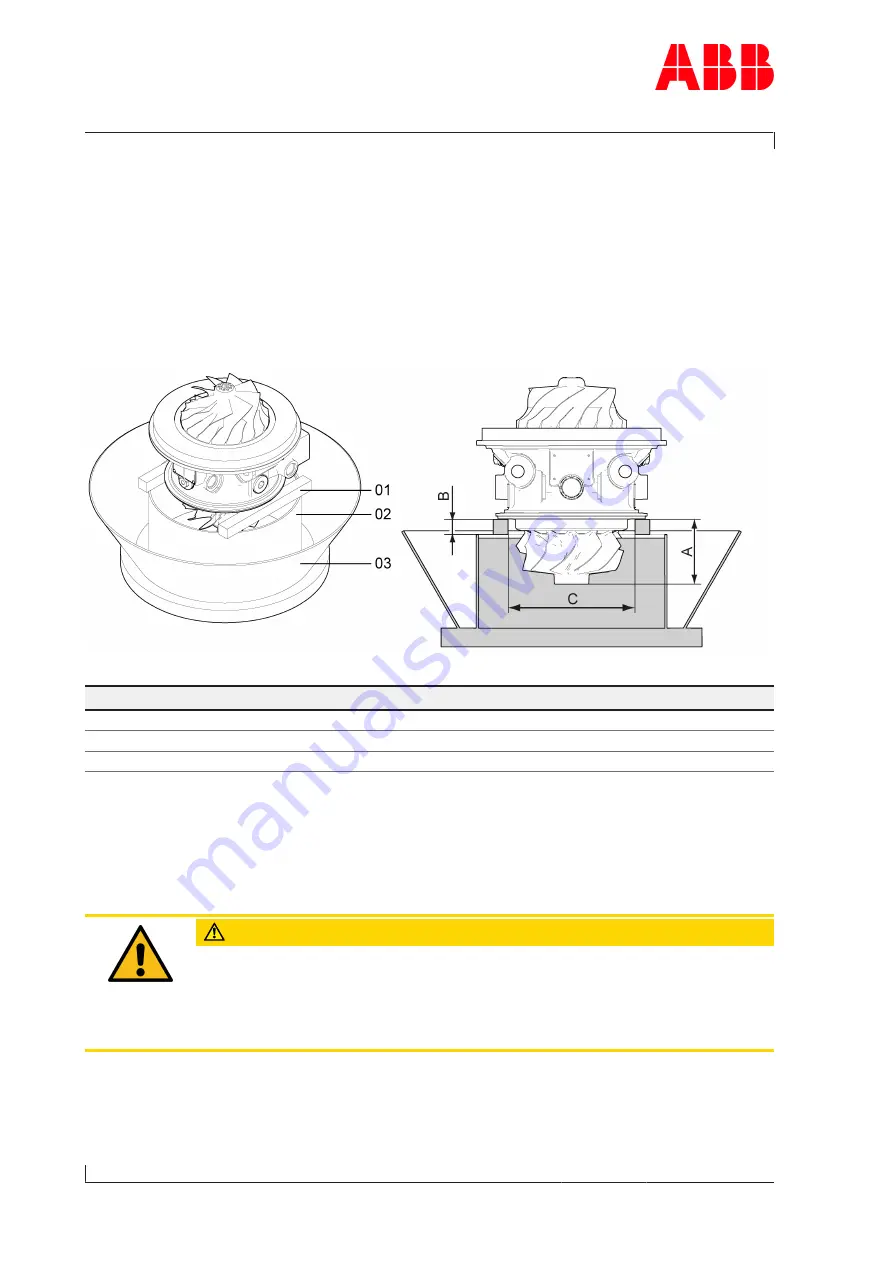

Fig. 16: Soaking contamination of the turbine

Product

A [mm]

B [mm]

C [mm]

TPS44

115

20

155

TPS48

115

29

180

TPS52

135

35

215

Table 12: Dimensions of the cleaning container

To soak the layers of contamination on the turbine, the cartridge group can be immersed

vertically in a container (02) with fluid.

u

Place the container (02) inside a larger container (03) so that the overflowing fluid can be

collected.

CAUTION

Selection of the cleaning agent

Cleaning agents which contain chlorine attack metals.

u

Use only pH-neutral cleaning agents which do not attack metals.

u

Observe safety data sheet.

u

Fill the container (02) with soaking fluid. To shorten the soaking time, the fluid can be

heated up to a maximum of 60 ºC.

Page

36

/

77