Operation Manual / 4 Product description / A100-M axial

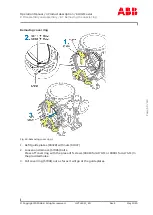

8 Disassembly and assembly / 8.10 Fitting the spinner nose cone

© Copyright 2020 ABB. All rights reserved.

HZTL4033_EN

Rev.E

May 2020

1. Remove residual glue from the inner thread of the threaded stud (25008) by using a

screw tap.

2. Clean and degrease the inner thread of the threaded stud and socket screw (25013).

3. Coat the outer contact surface (A) between the spinner nose cone and the compressor

wheel over its entire circumference with Molykote® TP42.

4. Apply Loctite® 542 to the inner thread of the threaded stud.

Fig. 53: Fitting the spinner nose cone (25012)

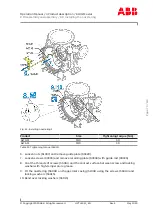

Product

Size

Tightening torque [Nm]

A170-M

M8

20

A175-M

M10

40

Table 41: Tightening torque (25013)

Always use a new socket screw (25013) and washer (25014) from the customer spare part set

(97070).

5. Fit the spinner nose cone and secure with washer (25014) and socket screw (25013). The

following must be taken into account:

u

The tightening torque must be applied by two people. One person tightens socket

screw (25013), while the second person holds the compressor wheel (25000).

u

Apply tightening torque constantly, avoid jerky movements. Observe tightening torque.

u

Do not repeat the tightening of socket screw (25013).

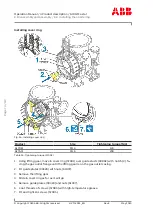

6. Measure and note down distance Z between spinner nose cone and compressor wheel at

no less than three points around the circumference.

Permissible distance Z:

0.1 – 0.7 mm

Permissible difference of the measurements:

± 0.1 mm

Page

81

/

113