Operation Manual / TPL76-C32/-C33/-C34/-C35

8 Disassembly and assembly / 8.8 Dismantling and fitting nozzle ring

at turbine end

© Copyright 2021 . All rights reserved.

HZTL2485_EN

Rev.G

July 2021

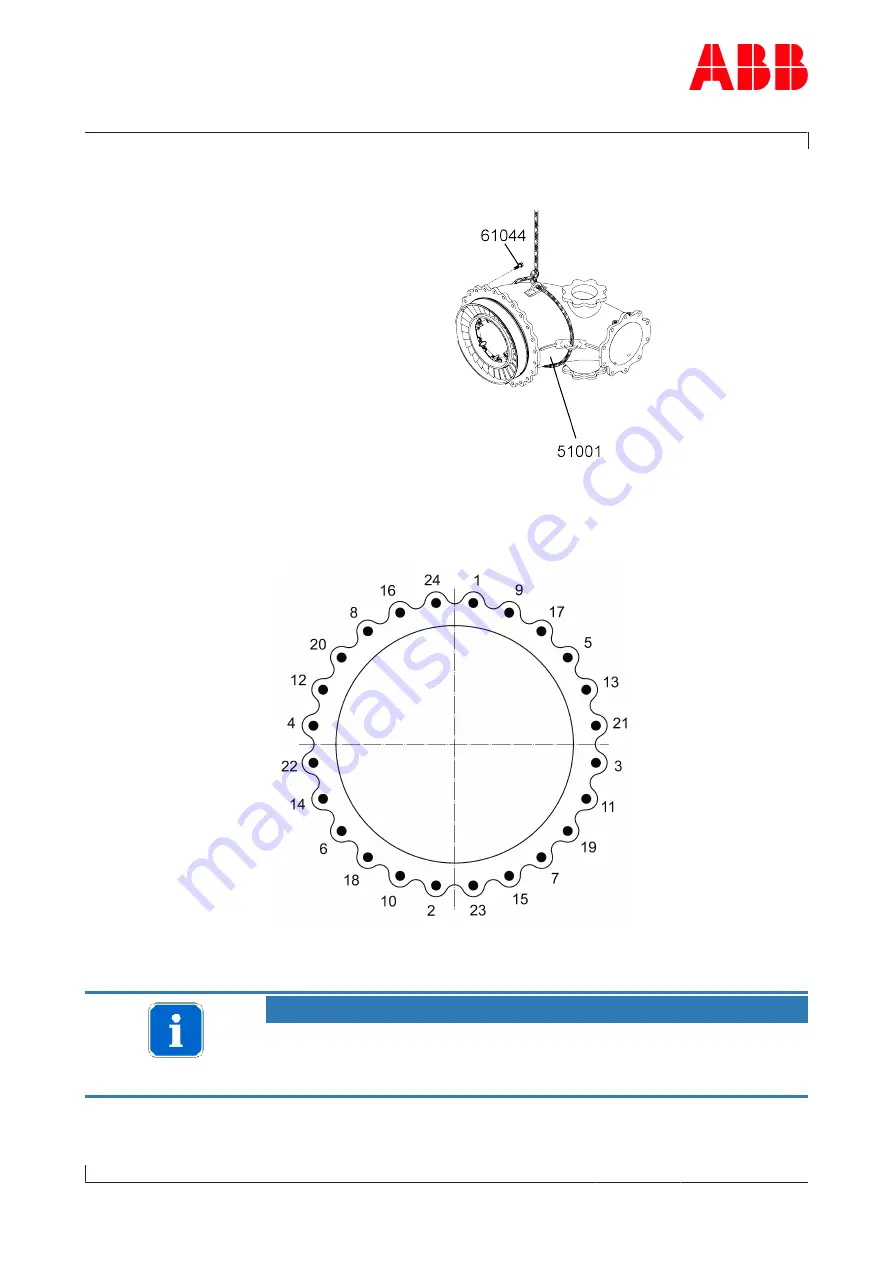

Tightening flange connection

u

Fit screws (61044).

u

Tighten screws (61044) in accordance with following procedure and in

following order:

Flange connection

u

Tighten screws crosswise

NOTICE

Screw tightening sequence

The screw positioning numbers must be marked on the component.

This enables simple and efficient tightening.

Page

114

/

133