Operation Manual / A150-M56/66/57/67 - A155-M..

10 Dismantling and fitting with removed air inlet and gas outlet / 10.9

Measuring clearance A and B

© Copyright 2022 ABB. All rights reserved.

HZTL4032_EN

Rev.S

February 2022

10.9

Measuring clearance A and B

u

Measure and record clearances A and B after the removal and before the installation of

the cartridge group.

u

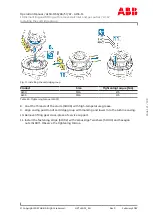

Attach the dial indicator and align it for the respective clearance as per the illustration.

Fig. 66: Measuring clearance A and B

Product

A [mm]

B [mm]

A150-M

0.12 ... 0.22

0.72 ... 1.28

A155-M

0.12 ... 0.22

0.79 ... 1.40

Table 47: Permissible clearances A and B

1. Move the rotor to and fro up to the stop. In order to obtain a correct measurement, elev-

ate the turbine a little.

2. Measure clearance A and compare it with the permissible values in the table.

3. Raise the compressor and push the turbine down at the same time.

4. Raise the turbine and push the compressor down at the same time.

5. Measure clearance B and compare it with the permissible values in the table.

CAUTION

Clearances outside the tolerance

Serious damage to engines or property can be caused by clearances outside

the tolerance and excessively worn parts.

u

Have the components assessed and, if necessary, replaced by a Turbo

Systems service station.

Page

116

/

198

Summary of Contents for HT613685

Page 2: ......