ProcessMaster FEP610, HygienicMaster FEH610

| OI/FEP610/FEH610-EN Rev. B 13

5

Installation

5.1

Installation conditions

5.1.1

General information

The following points must be observed during installation:

— The flow direction must correspond to the marking, if

present.

— The maximum torque for all flange screws must be

complied with.

— Secure the flange bolts and nuts against pipe vibration.

— The devices must be installed without mechanical tension

(torsion, bending).

— Install flange devices / wafer-type devices with plane

parallel counterflanges and use appropriate gaskets only.

— Only gaskets made from a material that is compatible with

the measuring medium and measuring medium

temperature may be used.

— Gaskets must not extend into the flow area, since possible

turbulence could influence the accuracy of the device.

— The piping may not exert any inadmissible forces or

torques on the device.

— Make sure temperature limits are not exceeded operating

the device.

— Vacuum shocks in the piping should be avoided to prevent

damage to the liners (PTFE). Vacuum shocks can destroy

the device.

— Do not remove the sealing plugs in the cable glands until

you are ready to install the electrical cable.

— Make sure the gaskets for the housing cover are seated

correctly. Carefully gasket the cover. Tighten the cover

fittings.

— The transmitter with a remote mount design must be

installed at a largely vibration-free location.

— Do not expose the transmitter and sensor to direct

sunlight. Provide appropriate sun protection as necessary.

— When installing the transmitter in a control cabinet, make

sure adequate cooling is provided.

— In case of a remote mounted transmitter make sure that

the sensor and the transmitter have been assigned

correctly. Compatible devices have the same end

numbers on the name plate, e.g. flowmeter sensor X001

belongs to transmitter Y001 or flowmeter sensor X002

belongs to transmitter Y002.

5.1.2

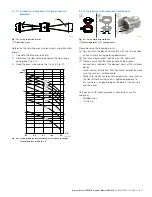

Brackets and supports

NOTE

Potential damage to device!

Improper support for the device may result in deformed

housing and damage to internal magnet coils.

Place the supports at the edge of the flowmeter sensor

housing (see arrows in Fig. 9).

Fig. 9:

Support for meter sizes larger than DN 400

Devices with meter sizes larger than DN 400 must be mounted

with support on a sufficiently strong foundation.

5.1.3

Gaskets

The following points must be observed when installing

gaskets:

— For achieve the best results, ensure the gaskets fit

concentrically with the meter tube

— To ensure that the flow profile is not distorted, the gaskets

must not protrude into the piping.

— The use of graphite with the flange or process connection

gaskets is prohibited, because an electrically conductive

coating may form on the inside of the meter tube.

Devices with a hard rubber, soft rubber liner

— Devices with a hard / soft rubber liner always require

additional gaskets.

— ABB recommends using gaskets made from rubber or

rubber-like sealing materials.

— When selecting the gaskets, ensure that the tightening

torques specified in chapter "Torque information" on

page 87 are not exceeded.

Devices with a PTFE, PFA or ETFE liner

— In principle, devices with a PTFE, PFA or ETFE liner do not

require additional gaskets.

G10649