ProcessMaster FEP610, HygienicMaster FEH610

| OI/FEP610/FEH610-EN Rev. B 9

2.2

Model variants

Integral mount design

For devices with an integral mount design, the transmitter and

the flowmeter sensor form a single mechanical unit

Remote mount design

For devices with a remote mount design, the transmitter and

flowmeter sensor are mounted in separate locations.

The electrical connection between the transmitter and the

flowmeter sensor is provided by a signal cable.

When the minimum conductivity of the measuring medium is

20 μS/cm, a maximum signal cable length of 50 m (164 ft) is

possible.

Notes on ProcessMaster

The ProcessMaster flowmeter sensor is available in two

models, which are distinguished by the design level (A / B).

2.3

Measuring principle

Measurements performed by the electromagnetic flowmeter

are based on Faraday’s law of induction. A voltage is

generated in a conductor when it moves through a magnetic

field.

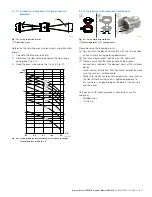

Fig. 3:

Electromagnetic flowmeter schematic

1

Magnet coil

2

Measuring tube in electrode plane

3

Signal

electrode

v

D

B

U

~

1

v

D

qv

4

2

qv

U ~

1

U

1

Signal voltage

B Magnetic

induction

D Electrode

spacing

v Average

flow

velocity

q

v

Volume flow

This principle is applied to a conductive fluid in the measuring

tube through which a magnetic field is generated

perpendicular to the flow direction (see Fig. 3).

The voltage induced in the fluid is measured by two electrodes

located diametrically opposite each other. This signal voltage

is proportional to the magnetic induction, the electrode

spacing and the average flow velocity.

Considering that the magnetic induction and the electrode

spacing are constant values, a proportionality exists between

the signal voltage UE and the average flow velocity.

From the equation for calculating the volume flowrate, it

follows that the signal voltage is linearly proportional to the

volume flowrate.

The induced voltage is converted by the transmitter to

standardized, analog and digital signals.

G12000

U₁

y

z

x

v

B

D

E

1

2

2