ABB i-bus® KNX

PRODUCT OVERVIEW

Valve outputs

VC/S 4.1.1

VC/S 4.2.1

Thermoelectric Valve Drives (PWM)

4

4

Magnetic valve drives (open/closed)

4

4

Tab. 4: Valve outputs

Physical inputs

VC/S 4.1.1

VC/S 4.2.1

Analog room control units

4

4

Binary sensors (floating)

12

12

Temperature sensors

8

8

Tab. 5: Physical inputs

3.4.1

Inputs

Function

a

b

c

d

e

f

g

h

i

j

k

l

Temperature sensor

PT100

x

x

x

x

x

x

x

x

PT1000

x

x

x

x

x

x

x

x

KT/KTY

x

x

x

x

x

x

x

x

KT/KTY user-defined

x

x

x

x

x

x

x

x

NTC10k

x

x

x

x

x

x

x

x

NTC20k

x

x

x

x

x

x

x

x

NI‑1000

x

x

x

x

x

x

x

x

Analog room control unit

x

x

x

x

Binary sensor (floating)

x

x

x

x

x

x

x

x

x

x

x

x

Dew point sensor (floating)

x

x

x

x

x

x

x

x

x

x

x

x

Fill level sensor (floating)

x

x

x

x

x

x

x

x

x

x

x

x

Window contact (floating)

x

x

x

x

x

x

x

x

x

x

x

x

Tab. 6: Function of the inputs

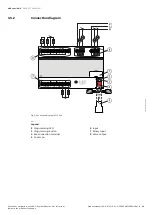

3.4.2

Outputs

3.4.2.1

Valve outputs

Function

A

B

C

D

Thermoelectric Valve Drives (PWM)

x

x

x

x

Magnetic valve drives (open/closed)

x

x

x

x

Fault detection (overload/short circuit)

x

x

x

x

Tab. 7: Function of the valve outputs

Product manual | EN-US | VC/S 4.x.1 | 2CDC508220D0211 Rev. B

11

Note about navigation in the PDF: Key combination 'Alt + left arrow'

jumps to the previous view/page