Note

Action

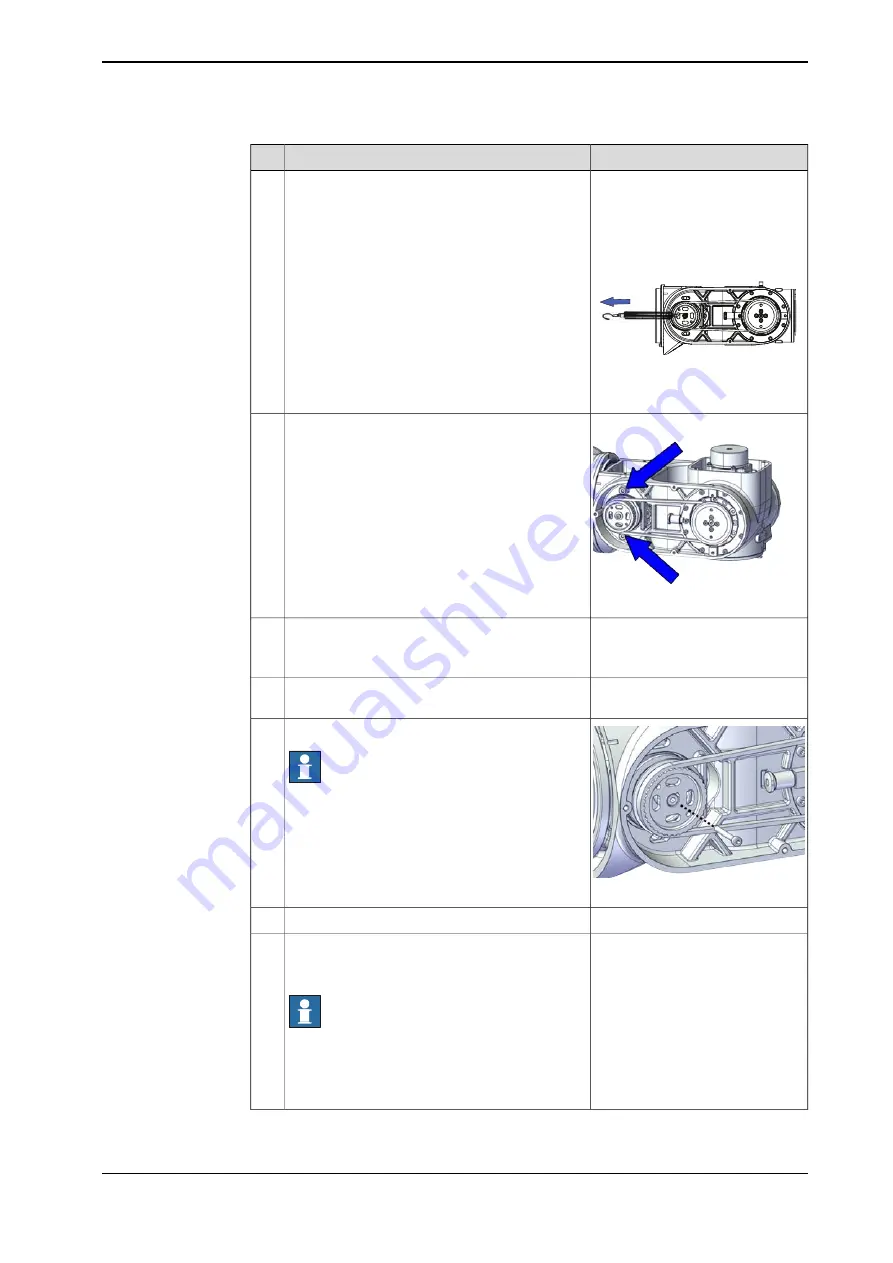

Initial referenced force for used

belt: 13.7±1 N (for reference only)

Use a handheld dynamometer hooking to the

screw and pull the dynamometer to reach the ini-

tial referenced force.

10

Initial referenced force for new belt:

19.6±1 N

xx2200000548

Tightening torque: 2.8 Nm

Secure the motor with the screws.

11

xx2200000042

Used belt: 123-131 Hz

Use a sonic tension meter to measure the timing

belt tension.

12

New belt:132-169 Hz (for reference

only)

If the timing belt tension does not meet the require-

ment, loosen the motor screws and readjust.

13

xx2200000547

Remove the adjustment screw from the motor.

Note

Pay attention to the screw turning direction. Incor-

rect direction may weaken the brake capacity of

the motor.

14

Tightening torque: 0.8 Nm

Refit the pulley screw.

15

Connect the power supply to axis-4 motor and

release the axis-4 brake to move the axis 4 to zero

position. Then, disconnect the power supply.

Note

The robot is not connected to the controller during

replacement, power must be supplied to the con-

nector R1.MP according to the section

power to connector R1.MP on page 56

.

16

Continues on next page

Product manual - IRB 1010

239

3HAC081964-001 Revision: B

© Copyright 2022 ABB. All rights reserved.

5 Repair

5.4.4 Replacing the wrist unit

Continued

Summary of Contents for IRB 1010

Page 1: ...ROBOTICS Product manual IRB 1010 ...

Page 8: ...This page is intentionally left blank ...

Page 14: ...This page is intentionally left blank ...

Page 36: ...This page is intentionally left blank ...

Page 46: ...This page is intentionally left blank ...

Page 80: ...This page is intentionally left blank ...

Page 306: ...This page is intentionally left blank ...

Page 312: ...This page is intentionally left blank ...

Page 326: ...This page is intentionally left blank ...

Page 328: ...This page is intentionally left blank ...

Page 332: ......

Page 333: ......