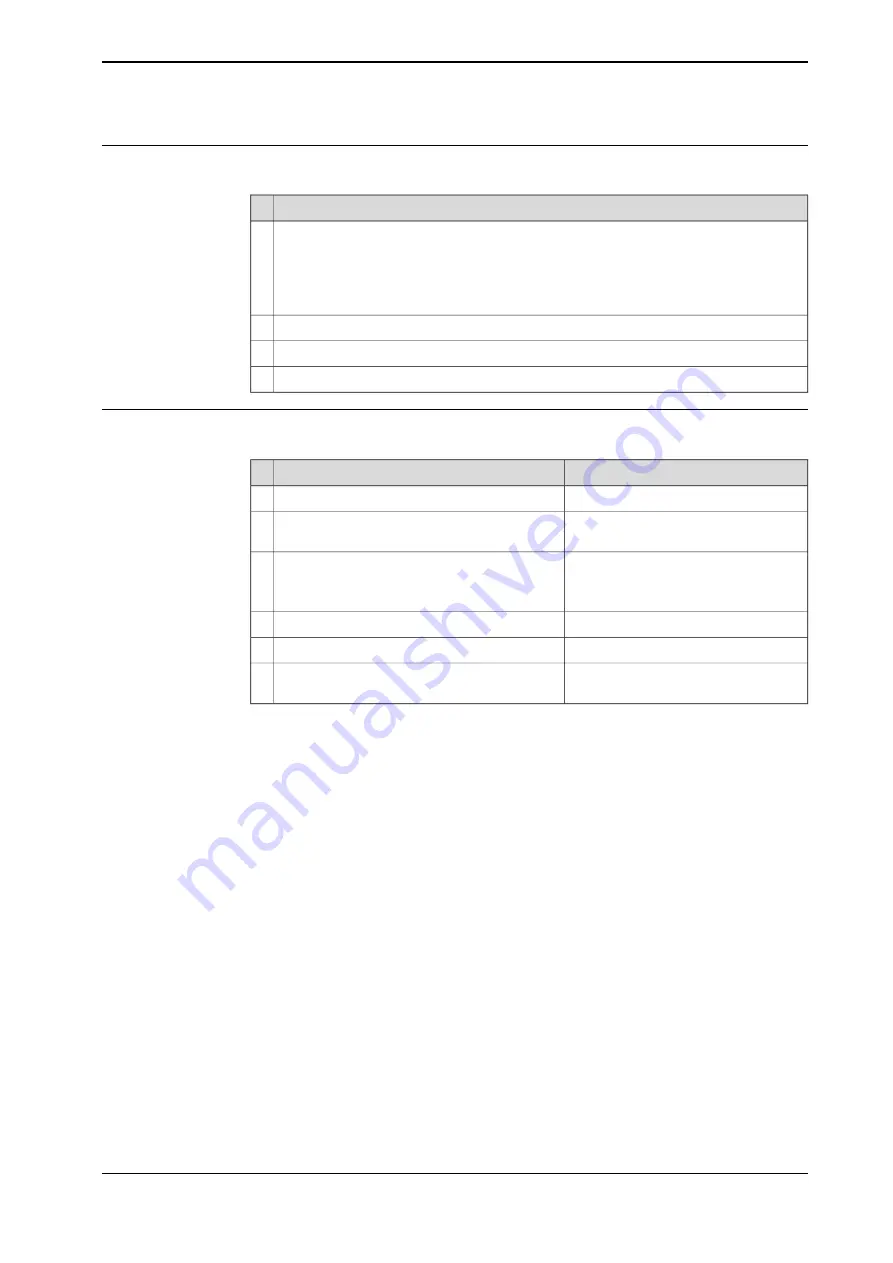

Flange seals and static seals

The following procedure describes how to fit flange seals and static seals.

Action

Check the flange surfaces. They must be even and free from pores.

1

It is easy to check flatness using a gauge on the fastened joint (without sealing com-

pound).

If the flange surfaces are defective, the parts may not be used because leakage could

occur.

Clean the surfaces properly in accordance with the recommendations of ABB.

2

Distribute the sealing compound evenly over the surface, preferably with a brush.

3

Tighten the screws evenly when fastening the flange joint.

4

O-rings

The following procedure describes how to fit o-rings.

Note

Action

Ensure that the correct o-ring size is used.

1

Defective o-rings, including damaged

or deformed o-rings, may not be used.

Check the o-ring for surface defects, burrs,

shape accuracy, or deformation.

2

Defective o-rings may not be used.

Check the o-ring grooves.

3

The grooves must be geometrically correct and

should be free of pores and contamination.

Lubricate the o-ring with grease.

4

Tighten the screws evenly while assembling.

5

Make sure that no grease is left on the robot

surface.

6

Product manual - IRB 120

117

3HAC035728-001 Revision: N

© Copyright 2009-2017 ABB. All rights reserved.

4 Repair

4.2.1 Mounting instructions for seals

Continued

Summary of Contents for IRB 120

Page 1: ...ROBOTICS Product manual IRB 120 ...

Page 8: ...This page is intentionally left blank ...

Page 90: ...This page is intentionally left blank ...

Page 114: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 250: ...This page is intentionally left blank ...

Page 254: ...This page is intentionally left blank ...

Page 264: ...This page is intentionally left blank ...

Page 270: ......

Page 271: ......