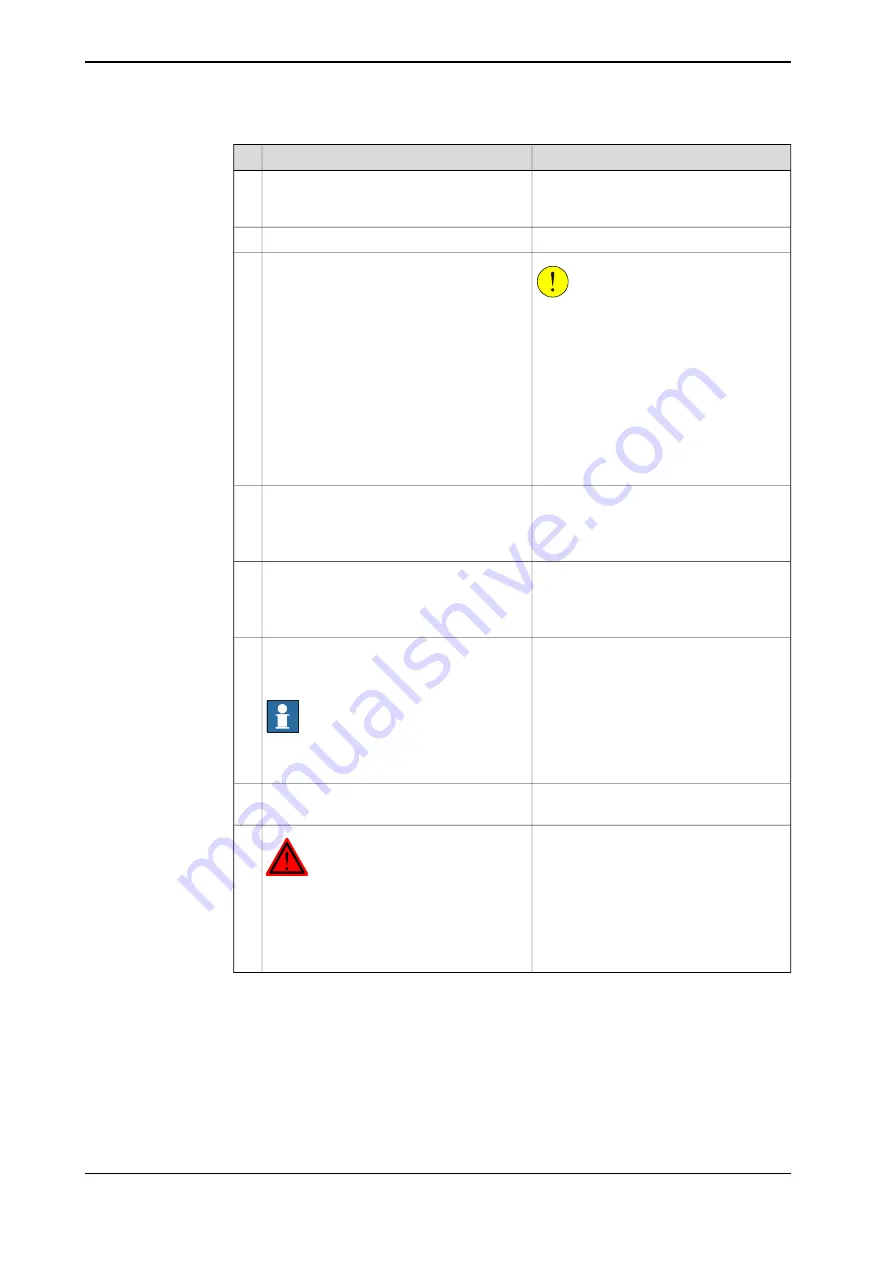

Information

Action

See the figure in:

•

Location of the Encoder Interface

board on page 148

Fit the

plate

where the battery is fitted.

4

Reconnect the battery cable.

5

CAUTION

Arrange the cable harness inside correctly

in a way that:

•

it is not damaged in the continued

refitting process

•

extra wear will not occur after pro-

duction is restarted, which will

shorten the life of the harness.

See section

•

Refitting the cable harness on

page 134

Push the cable harness main carefully into

the

base

.

6

Tightening torque: 2 Nm.

Secure the

plate

with its attachment screws.

7

See the figure in:

•

Location of the Encoder Interface

board on page 148

Tightening torque: 4 Nm.

Refit the

base cover

.

8

See the figure in:

•

Location of the Encoder Interface

board on page 148

Clean Room robots: seal and paint the joints

that have been opened. See

Note

After all repair work, wipe the robot free

from particles with spirit on a lint free cloth.

9

See chapter:

•

Recalibrate the robot.

10

DANGER

Make sure all safety requirements are met

when performing the first test run. These

are further detailed in the section

- First test run may cause injury or damage!

on page 47

.

11

150

Product manual - IRB 120

3HAC035728-001 Revision: N

© Copyright 2009-2017 ABB. All rights reserved.

4 Repair

4.3.3 Replacing the Encoder Interface board

Continued

Summary of Contents for IRB 120

Page 1: ...ROBOTICS Product manual IRB 120 ...

Page 8: ...This page is intentionally left blank ...

Page 90: ...This page is intentionally left blank ...

Page 114: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 250: ...This page is intentionally left blank ...

Page 254: ...This page is intentionally left blank ...

Page 264: ...This page is intentionally left blank ...

Page 270: ......

Page 271: ......