2.7 Start of robot in cold environments

Introduction

This section describes how to start the robot in a cold environment if it is not starting

the normal way.

Problems with starting the robot

Event message from Motion supervision

Use this procedure if an event message indicates a problem with Motion supervision

at start-up.

Note

Action

Turn off motion supervision.

1

Start the robot.

2

When the robot has reached normal working temper-

ature, the motion supervision can be turned on

again.

3

Robot stopping with other event message

Use this procedure if the robot is not starting.

Note

Action

The speed can be regulated with the

RAPID instruction

VelSet

.

Start the robot with its normal program but

with reduced speed.

1

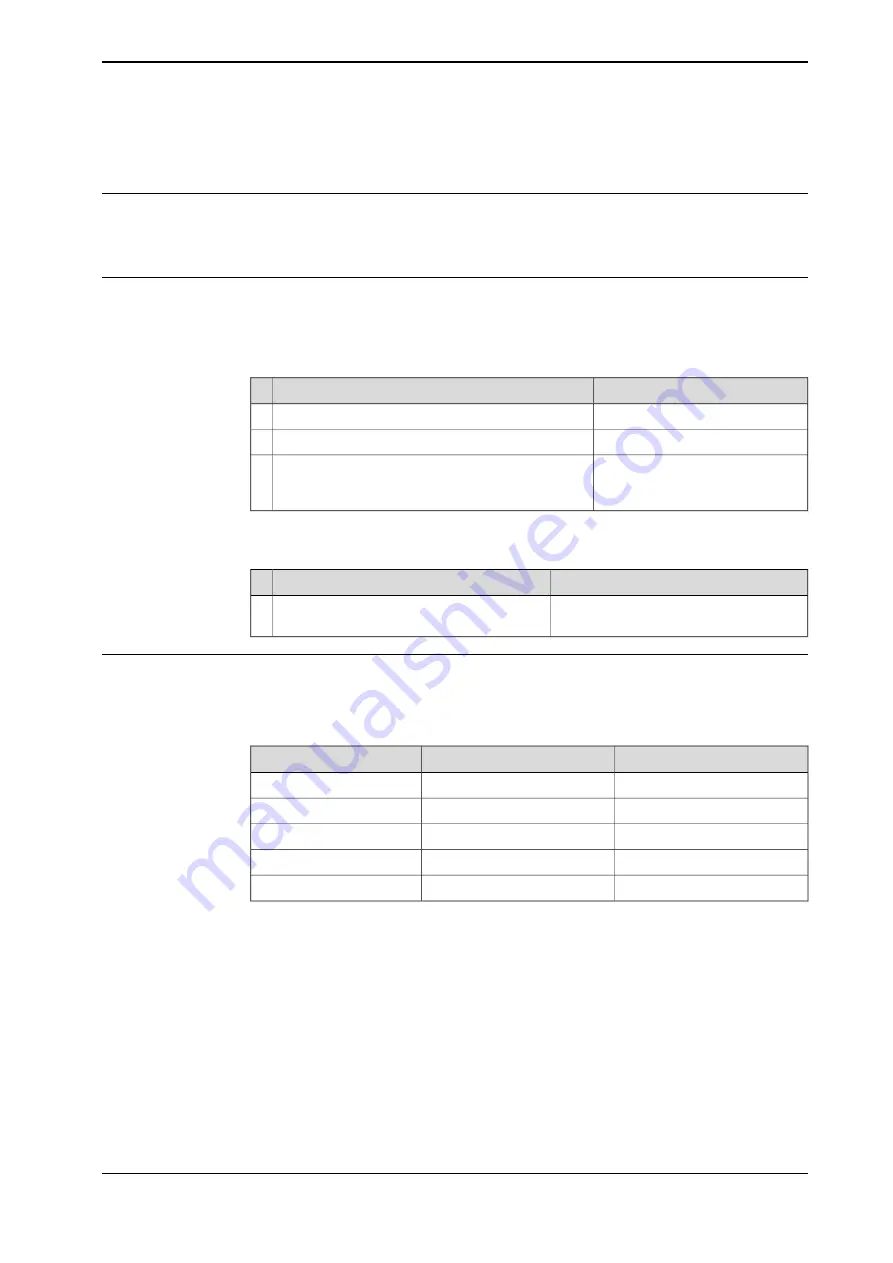

Adjusting the speed and acceleration during warm-up

Depending on how cold the environment is and what program is being used, the

speed might need to be ramped up until reached maximum. The table shows

examples of how to adjust the speed:

Speed/velocity

AccSet

Work cycles

v100 (100 mm/s)

20, 20

3 Work cycles

v400 (400 mm/s)

40, 40

5 Work cycles

v600 (600 mm/s)

60, 60

5 Work cycles

v1000 (1000 mm/s)

100, 100

5 Work cycles

Max.

100, 100

More than 5 Work cycles

If the program consists of large wrist movements, it is possible that the reorientation

velocity, which is always high in predefined velocities, needs to be included in the

ramping up.

Product manual - IRB 120

89

3HAC035728-001 Revision: N

© Copyright 2009-2017 ABB. All rights reserved.

2 Installation and commissioning

2.7 Start of robot in cold environments

Summary of Contents for IRB 120

Page 1: ...ROBOTICS Product manual IRB 120 ...

Page 8: ...This page is intentionally left blank ...

Page 90: ...This page is intentionally left blank ...

Page 114: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 250: ...This page is intentionally left blank ...

Page 254: ...This page is intentionally left blank ...

Page 264: ...This page is intentionally left blank ...

Page 270: ......

Page 271: ......