Note

Action

xx1700000117

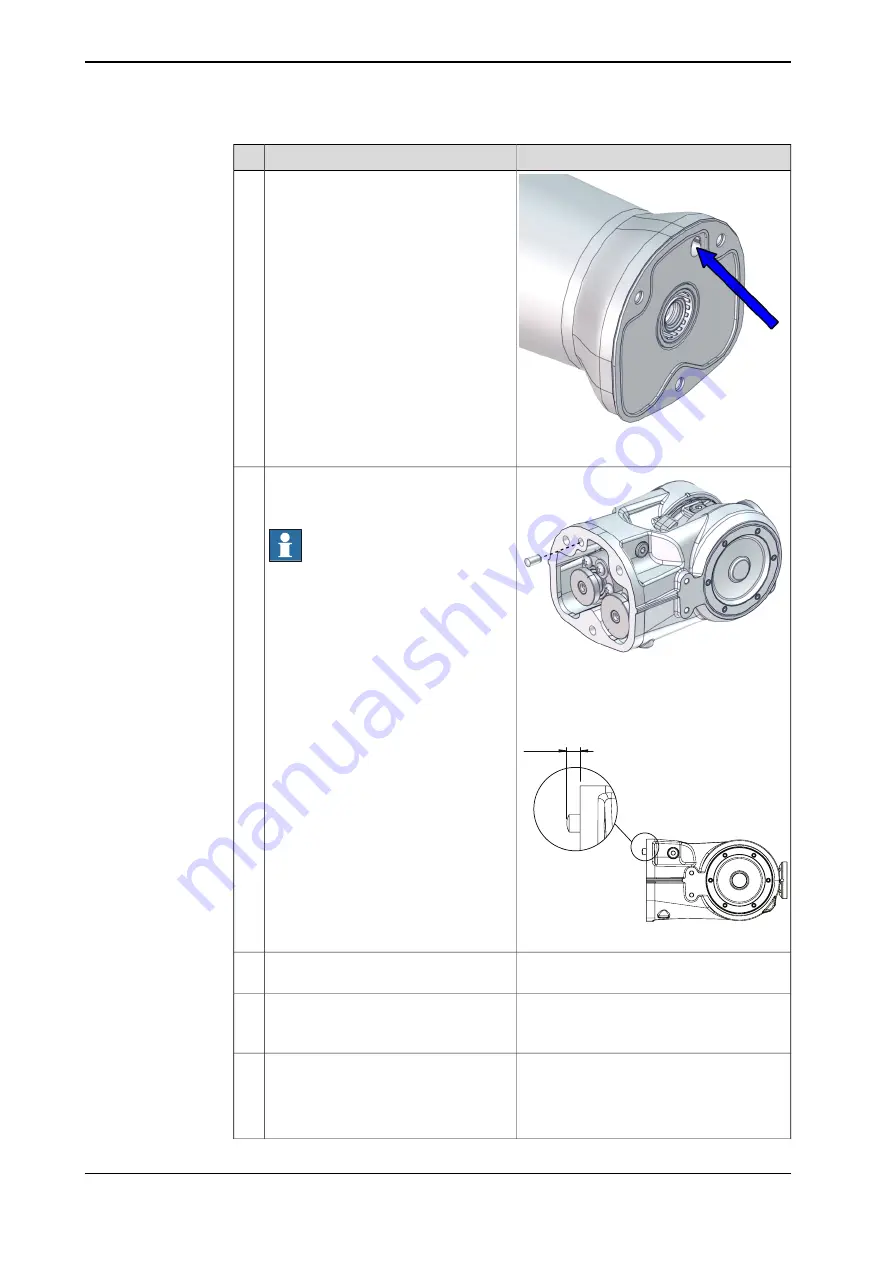

With the new spare part wrist there is a

parallel pin enclosed.

The parallel pin must be installed on the

wrist if the robot is calibrated with the

Axis Calibration method.

If the calibration method is unknown,

look at the tubular shaft interface. If it

has an elongated hole, install the parallel

pin into the wrist, according to the next

step.

4

xx1700000118

If the robot is calibrated with Axis Calib-

ration. fit the parallel pin into the corres-

ponding hole in the wrist.

Note

If the parallel pin is not installed on a ro-

bot calibrated with Axis Calibration, the

calibration result will be affected negat-

ively.

5

Verify that the parallel pin sticks out from the

wrist according to the measurement given

below.

6 ±0,5

xx1700000119

Art. no. is specified in section

Lightly lubricate the o-ring sealingplate

with

grease

.

6

Connect to connector R3.MP5 or 6:

•

+: pin 7

•

-: pin 8

In order to release the brake, connect

the 24 VDC power supply to motors:

7

Use a new o-ring! Spare part no. is specified

in

Required equipment on page 201

.

Fit the

o-ring sealingplate

to the upper

arm. Fit the

wrist unit

to the upper arm

with the three attachment screws, while

making sure that the gears mate prop-

erly.

8

3 pcs, M8 x 25, tightening torque: 28 Nm.

Continues on next page

204

Product manual - IRB 1600/1660

3HAC026660-001 Revision: W

© Copyright 2006-2018 ABB. All rights reserved.

4 Repair

4.4.4 Replacing the wrist unit, IRB 1600

Continued

Summary of Contents for IRB 1600

Page 1: ...ROBOTICS Product manual IRB 1600 1660 ...

Page 8: ...This page is intentionally left blank ...

Page 18: ...This page is intentionally left blank ...

Page 48: ...This page is intentionally left blank ...

Page 152: ...This page is intentionally left blank ...

Page 336: ...This page is intentionally left blank ...

Page 372: ...This page is intentionally left blank ...

Page 388: ...This page is intentionally left blank ...

Page 396: ......

Page 397: ......