Information

Action

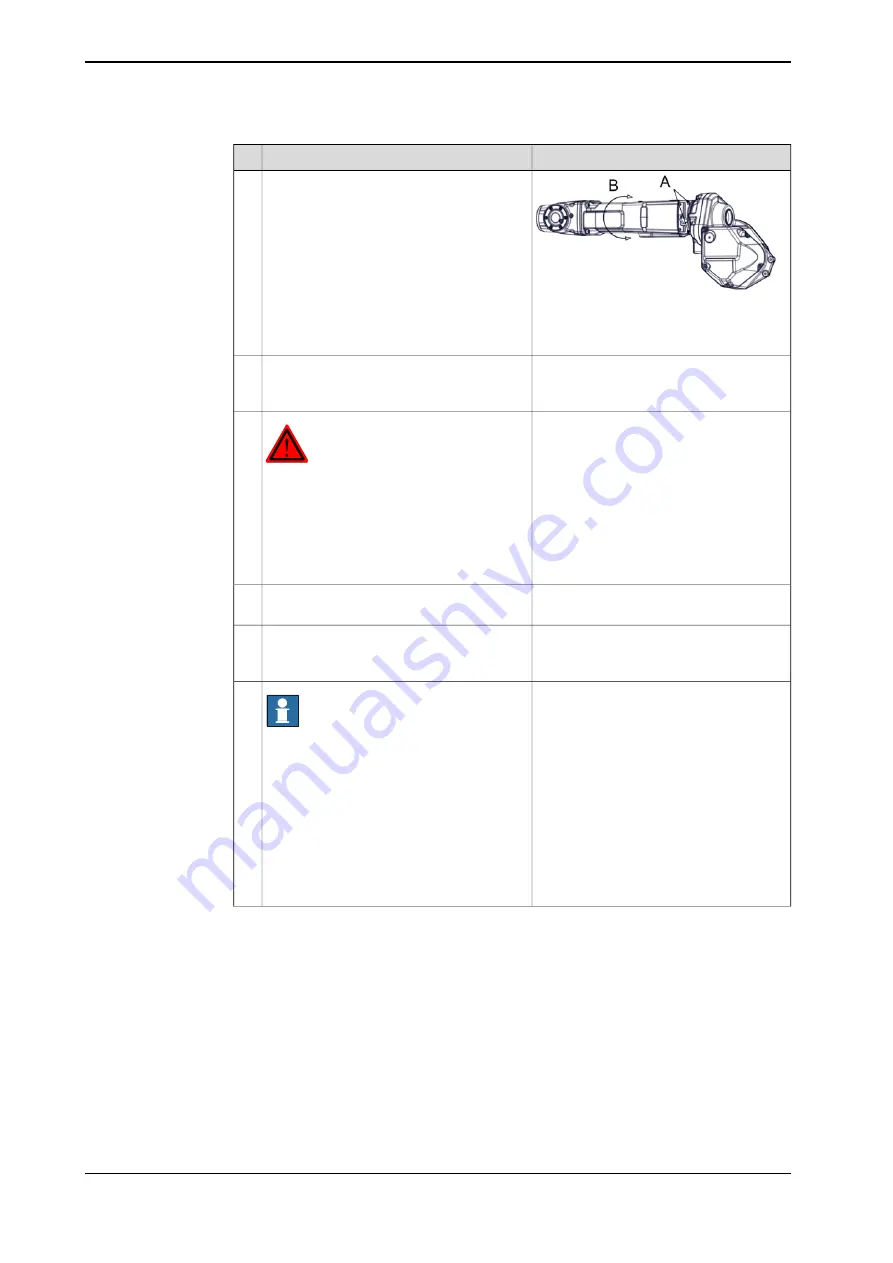

xx1500001260

Rotate the upper arm to access the two in-

ner attachment screws securing the cover

and remove them.

4

•

A: Inner attachment screws (2 pcs)

•

B: Directions of rotation

For the synchronization positions, see

Synchronization marks and synchroniza-

tion position for axes on page 341

Move the upper arm to sync. position.

5

DANGER

Before entering the robot working area, turn

off all:

•

Electric power supply to the robot

•

Hydraulic pressure supply to the ro-

bot

•

Air pressure supply to the robot

6

Remove all extra equipment fitted on the

upper arm and wrist.

7

How to remove the wrist see the section:

•

Replacing the wrist unit, IRB1660ID

on page 212

Remove the wrist and disconnect those

cables to motor axis 6.

8

Note

Make a note of the position of axis 4 before

continuing the removal process.

It is important to refit the mechanical stop

and cable harness spiral, with axis 4 in the

same position as it was before the removal.

If axis 4 has been moved, it must be re-

turned to the position it was when the

mechanical stop was removed.

This is due to risk of damage to the cable

harness.

9

Continues on next page

304

Product manual - IRB 1600/1660

3HAC026660-001 Revision: W

© Copyright 2006-2018 ABB. All rights reserved.

4 Repair

4.6.9 Replacement of motor, axis 5, IRB 1660ID

Continued

Summary of Contents for IRB 1600

Page 1: ...ROBOTICS Product manual IRB 1600 1660 ...

Page 8: ...This page is intentionally left blank ...

Page 18: ...This page is intentionally left blank ...

Page 48: ...This page is intentionally left blank ...

Page 152: ...This page is intentionally left blank ...

Page 336: ...This page is intentionally left blank ...

Page 372: ...This page is intentionally left blank ...

Page 388: ...This page is intentionally left blank ...

Page 396: ......

Page 397: ......