The guiding sleeves are absolutely needed if the robot is wall or angle mounted,

or if the robot is calibrated with AbsAcc.

Orienting and securing the robot to installation site

Note

Action

Make sure the installation site for the robot

conforms to the specifications in section

installation procedure on page 50

.

1

Hole configuration of the base is shown

in the figure

Prepare the installation site with attachment

holes.

If the robot is calibrated with AbsAcc, it must

be installed using guiding sleeves.

2

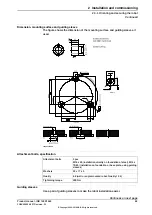

Dimension of mounting surface and the

guiding sleeves are shown in the figure

Dimension, mounting surface and

guiding sleeve on page 69

Detailed in section

Lift the robot to the installation site.

3

Guide the robot gently using two of the attach-

ment bolts while lowering it into its mounting

position.

4

Specified in section

.

Fit and tighten the

bolts and washers

in the

base attachment holes.

5

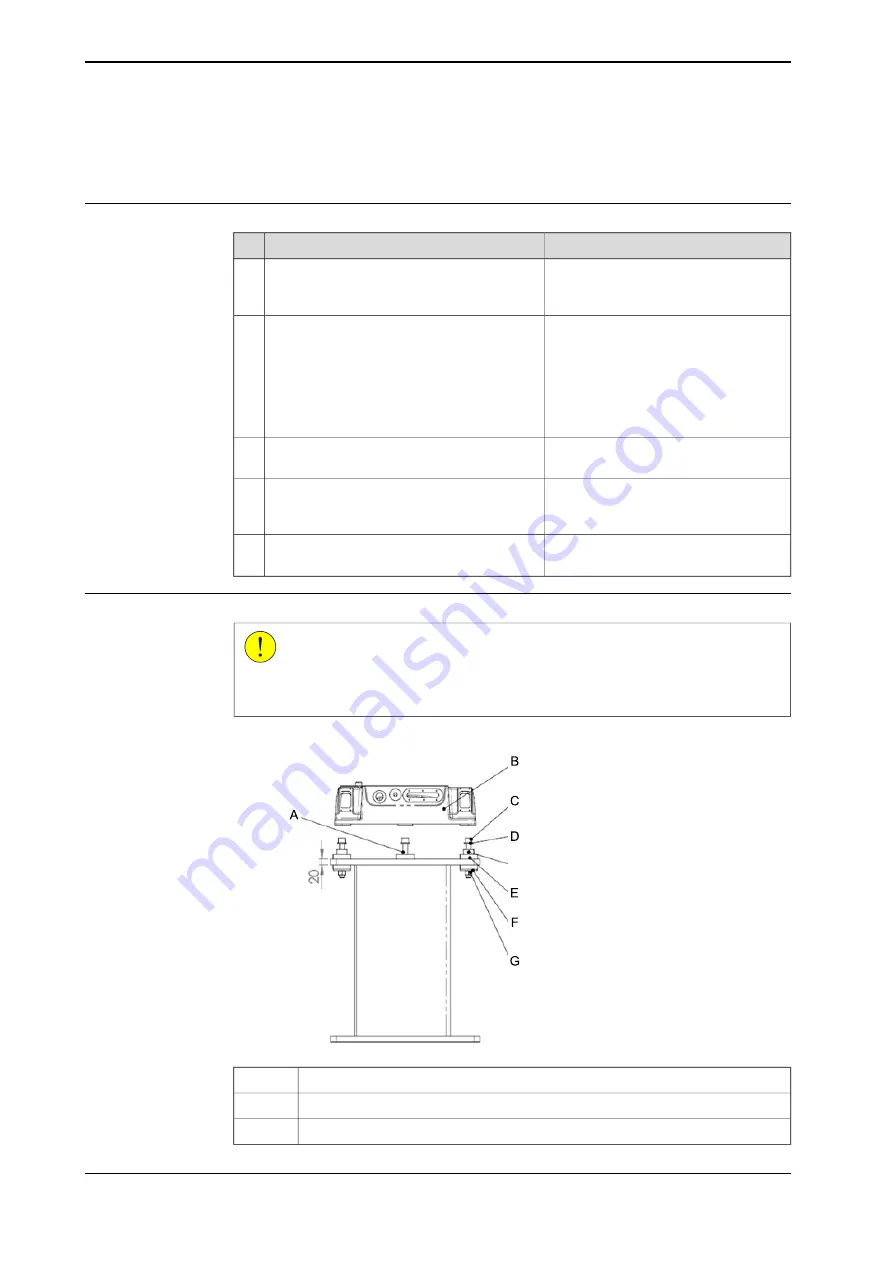

Isolating AW manipulator

CAUTION

If the manipulator is used for arc welding and is mounted on a pedestal, make

sure that the manipulator is isolated from the pedestal with isolators.

Attachment point, front (no guide sleeve)

A

Manipulator base

B

Screw M16x120

C

Continues on next page

70

Product manual - IRB 1600/1660

3HAC026660-001 Revision: W

© Copyright 2006-2018 ABB. All rights reserved.

2 Installation and commissioning

2.3.4 Orienting and securing the robot

Continued

Summary of Contents for IRB 1600

Page 1: ...ROBOTICS Product manual IRB 1600 1660 ...

Page 8: ...This page is intentionally left blank ...

Page 18: ...This page is intentionally left blank ...

Page 48: ...This page is intentionally left blank ...

Page 152: ...This page is intentionally left blank ...

Page 336: ...This page is intentionally left blank ...

Page 372: ...This page is intentionally left blank ...

Page 388: ...This page is intentionally left blank ...

Page 396: ......

Page 397: ......