Note/Illustration

Action

See the figure above.

Pull gently in one direction. Note the reading.

(The gear must not turn.)

11

See the figure above.

Then gently knock on the tool in the other direc-

tion and note the reading. The difference in

reading = gear play. The gear play should be

0.02 mm which corresponds to a reading on the

dial indicator of 0.13 mm.

12

4 pcs. Tightening torque: 35 Nm.

Tighten the four attachment screws.

13

Detailed in section

.

Perform a leak-down test.

14

Where to find type of oil and total

amount is detailed in

amount of oil in gearboxes on

page 92

Fill the gearbox with oil.

15

Shown in the figure

.

Refit the

connection box

and secure with the

three attachment screws and plain washers.

Make sure that the gasket is fitted properly!

16

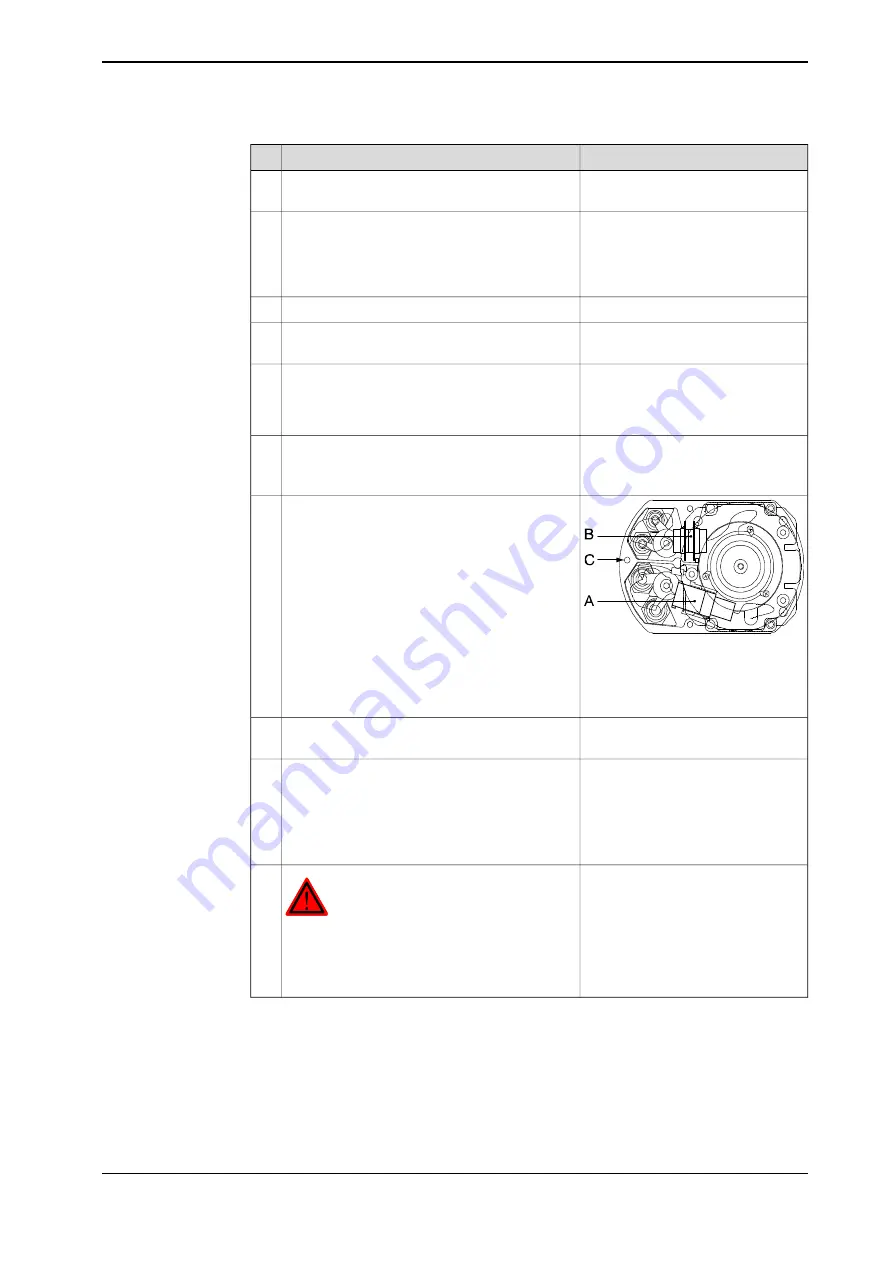

xx0200000401

Reconnect connectors R3.MP2 and R3.FB2.

17

•

A: R3.MP2

•

B: R3.FB2

•

C: Connection box

Shown in the figure

.

Refit the

cover

of the connection box.

18

Calibration is detailed in a separate

calibration manual enclosed with the

calibration tools.

Re-calibrate the robot.

19

General calibration information is in-

cluded in the section

DANGER

Make sure all safety requirements are met when

performing the first test run. These are further

detailed in the section

20

Product manual - IRB 2400

177

3HAC022031-001 Revision: P

© Copyright 2004-2018 ABB. All rights reserved.

4 Repair

4.7.2 Replacement of motor, axis 2

Continued

Summary of Contents for IRB 2400 Series

Page 1: ...ROBOTICS Product manual IRB 2400 ...

Page 8: ...This page is intentionally left blank ...

Page 18: ...This page is intentionally left blank ...

Page 204: ...This page is intentionally left blank ...

Page 220: ...This page is intentionally left blank ...

Page 232: ...This page is intentionally left blank ...

Page 234: ...This page is intentionally left blank ...

Page 240: ......

Page 241: ......