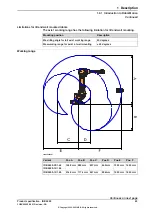

1.8.2 Performance according to ISO 9283

General

At rated maximum load, maximum offset and 1.6 m/s velocity on the inclined ISO

test plane, with all six axes in motion. Values in the table below are the average

result of measurements on a small number of robots. The result may differ

depending on where in the working range the robot is positioning, velocity, arm

configuration, from which direction the position is approached, the load direction

of the arm system. Backlashes in gearboxes also affect the result.

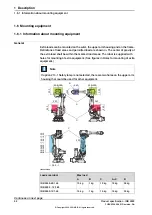

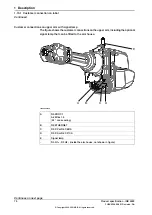

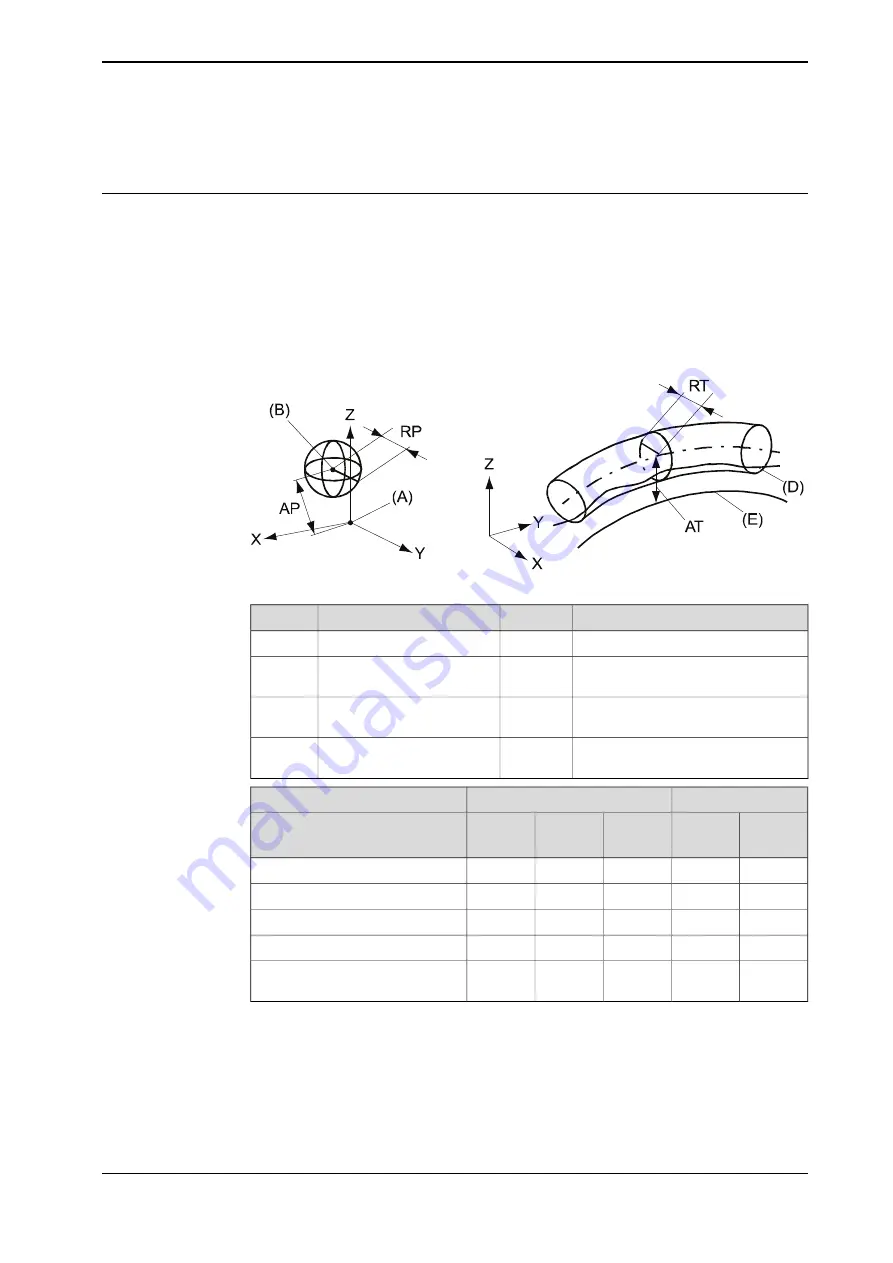

The figures for AP, RP, AT and RT are measured according to figure below.

xx0800000424

Description

Pos

Description

Pos

Programmed path

E

Programmed position

A

Actual path at program execution

D

Mean position at program

execution

B

Max deviation from E to average path

AT

Mean distance from pro-

grammed position

AP

Tolerance of the path at repeated

program execution

RT

Tolerance of position B at re-

peated positioning

RP

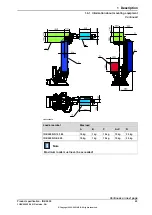

IRB 2600ID

IRB 2600

Description

-8/2.00

-15/1.85

-12/1.85

-12/1.65

-12/1.65

-20/1.65

-20/1.65

0.023

0.026

0.04

0.04

0.04

Pose repeatability, RP (mm)

0.033

0.014

0.03

0.03

0.03

Pose accuracy, AP

i

(mm)

0.27

0.30

0,16

0.14

0,13

Linear path repeatability, RT (mm)

0.70

0.80

0.68

0.60

0.55

Linear path accuracy, AT (mm)

0.063

0.05

0.03

0.02

0.00

Pose stabilization time, (PSt) to

within 0.2 mm of the position (s)

i

AP according to the ISO test above, is the difference between the reached position (position

manually modified in the cell) and the average position obtained during program execution.

Product specification - IRB 2600

65

3HAC035959-001 Revision: AA

© Copyright 2009-2021 ABB. All rights reserved.

1 Description

1.8.2 Performance according to ISO 9283

Summary of Contents for IRB 2600

Page 1: ...ROBOTICS Product specification IRB 2600 ...

Page 6: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 92: ...This page is intentionally left blank ...

Page 94: ...This page is intentionally left blank ...

Page 96: ......

Page 97: ......