1.10 Customer connections

1.10.1 Customer connection on robot

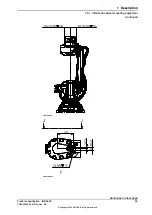

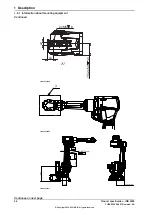

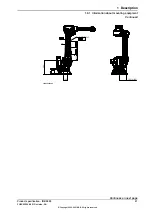

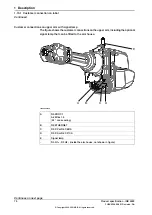

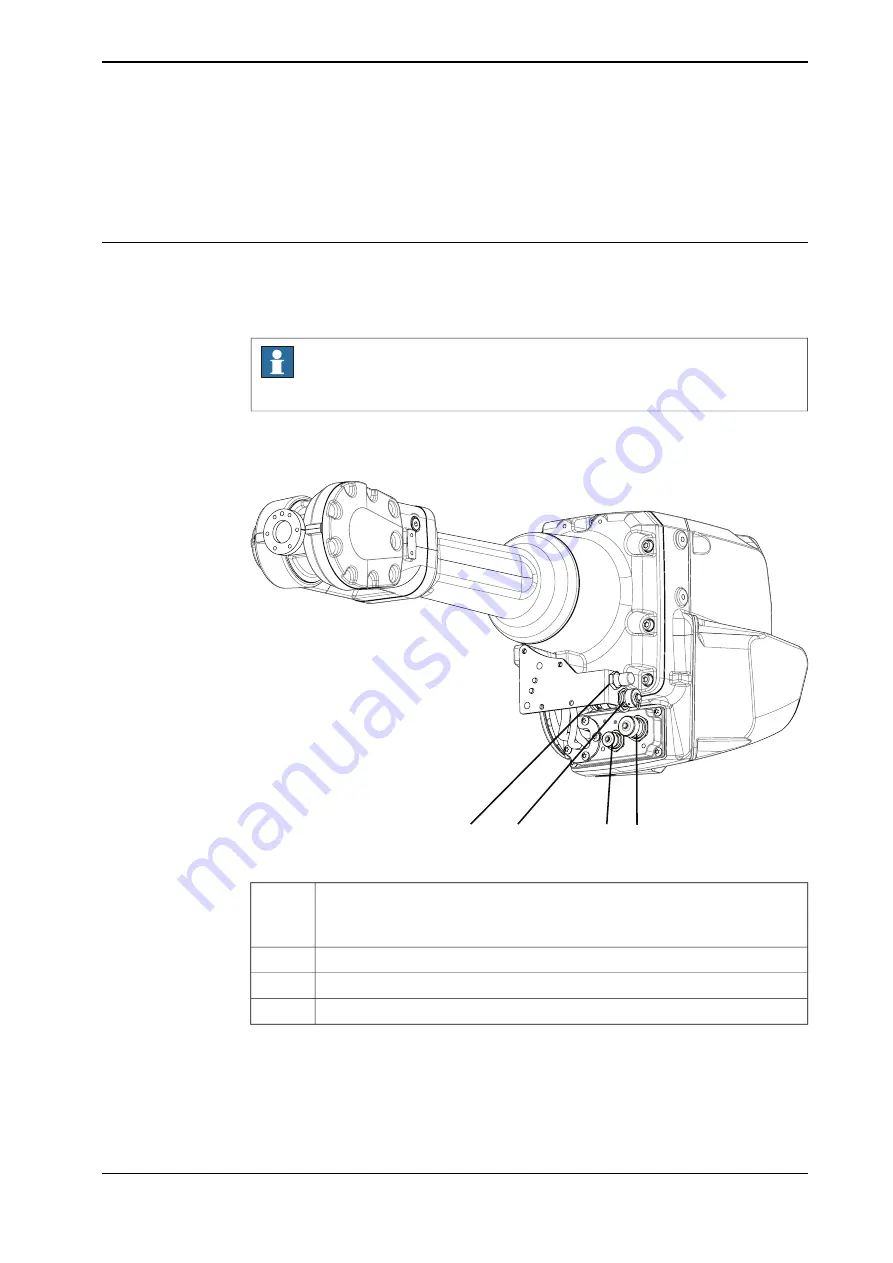

Location of customer connection

For the connection of extra equipment to the robot, cables and air hose are

integrated into the robot´s cabling, and there can be two UTOW71210SH06 and

one UTOW71626SH06 connector on the front part of the upper arm.

Note

The maximum leakage current for attached equipment must not exceed 10mA.

The customer connections are located on the robot as shown in the figure.

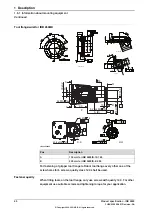

Customer connections on upper arm

A

B

C

D

xx2000001657

R2.PROC1

A

Air M16x1.5

(24° cone sealing)

R2.ETHERNET

B

R2.CP or R2.CBUS

C

R2.CS or R2.CP/CS

D

Continues on next page

Product specification - IRB 2600

69

3HAC035959-001 Revision: AA

© Copyright 2009-2021 ABB. All rights reserved.

1 Description

1.10.1 Customer connection on robot

Summary of Contents for IRB 2600

Page 1: ...ROBOTICS Product specification IRB 2600 ...

Page 6: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 92: ...This page is intentionally left blank ...

Page 94: ...This page is intentionally left blank ...

Page 96: ......

Page 97: ......