Note

Action

CAUTION

Always cut the paint with a knife and grind

the paint edge when disassembling parts.

See

Cut the paint or surface on the robot

before replacing parts on page 201

2

CAUTION

The gearbox weighs 51 kg

All lifting accessories used must be sized

accordingly!

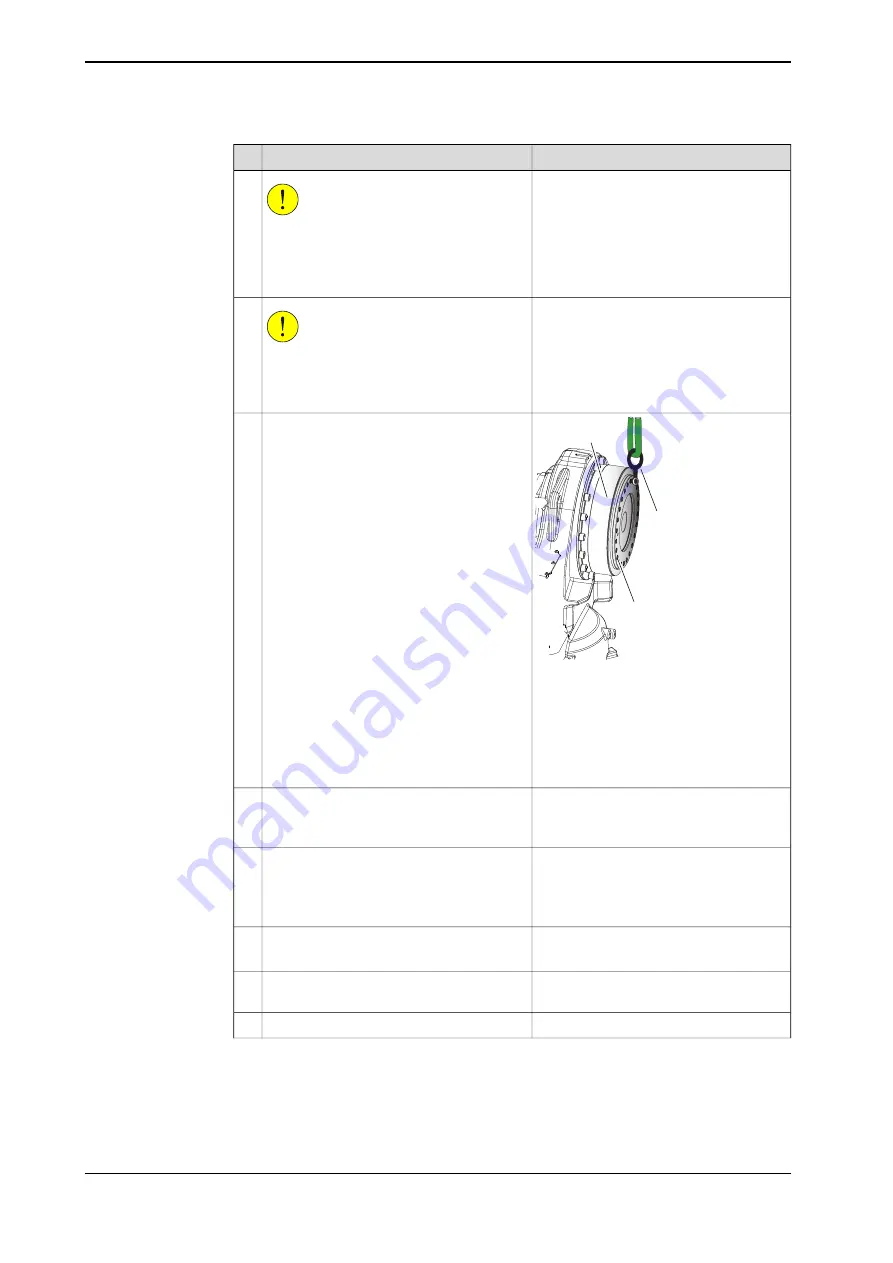

3

A

B

C

xx0800000445

Fit a

lifting lug

in the uppermost hole for

the attachment screws securing the lower

arm to the gearbox.

4

Parts:

•

A: Gearbox axis 2

•

B: Lifting lug

•

C: Holes for attachment screws

securing the lower arm to gearbox

axis 2.

Clean all assembly surfaces.

5

Remove any painting from the assembly

surfaces, with a knife.

O-ring, nitrile rubber: 3HAB3772-120.

Apply some grease on the o-ring before fit-

ting.

6

See the figure in:

•

Location of gearbox axis 2 on

page 336

Valid for Type C:

Replace if damaged.

Guide pin, M12x150: 3HAC13056-2

Fit two guide pins in opposite holes in the

frame.

7

Always use guide pins in pairs.

Secure the gearbox with a roundsling in an

overhead crane or similar.

8

Release the brakes of the axis 2 motor.

9

Continues on next page

342

Product manual - IRB 4600 Foundry Prime

3HAC040585-001 Revision: M

© Copyright 2013-2018 ABB. All rights reserved.

4 Repair

4.8.2 Replacing gearbox axis 2

Continued

Summary of Contents for IRB 4600 Foundry Prime

Page 1: ...ROBOTICS Product manual IRB 4600 Foundry Prime ...

Page 106: ...This page is intentionally left blank ...

Page 194: ...This page is intentionally left blank ...

Page 398: ...This page is intentionally left blank ...

Page 400: ...This page is intentionally left blank ...

Page 406: ......

Page 407: ......