Installation and Commissioning

Connecting Signals

Product Manual IRB 6400R

39

3.5 Connections

Detailed information about connection locations and functions will be found in chapter

11, Circuit Diagram.

3.5.1 To screw terminal

Panel unit and I/O units are provided with keyed screw terminals for cables with an

area between 0.25 and 1.5 mm

2

. A maximum of two cables may be used in any one

connection. The cable screen must be connected to the cabinet wall using EMC. It

should be noted that the screen must continue right up to the screw terminal.

The installation should comply with the IP54 (NEMA 12) protective standard.

Bend unused conductors backwards and attach them to the cable using a clasp, for

example. In order to prevent interference, ensure that such conductors are not con-

nected at the other end of the cable (antenna effect). In environments with much inter-

ference, disconnected conductors should be grounded (0 V) at both ends.

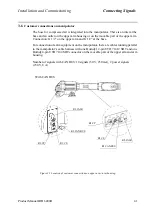

3.5.2 To connectors (option)

Industrial connectors with 4x16 pins for contact crimping (complies with DIN 43652)

can be found on the left-hand side or front of the cabinet (depending on the customer

order) See Figure 30 and Figure 21.

In each industrial connector there is space for four rows of 16 conductors with a max-

imum conductor area of 1.5 mm

2

. The pull-relief clamp must be used when connecting

the shield to the case.

The manipulator arm is equipped with round Burndy/Framatome connectors (customer

connector not included).

Bend unused conductors backwards and attach them to the cable using a clasp, for

example. In order to prevent interference, ensure that such conductors are not con-

nected at the other end of the cable (antenna effect). In environments with much inter-

ference, disconnected conductors should be grounded (0 V) at both ends.

When contact crimping industrial connectors, the following applies:

Using special tongs, press a pin or socket on to each non-insulated conductor.

The pin can then be snapped into the actual contact.

Push the pin into the connector until it locks.

Also, see instructions from contact supplier.

A special extractor tool must be used to remove pins from industrial connectors.

When two conductors must be connected to the same pin, both of them are pressed into

the same pin. A maximum of two conductors may be pressed into any one pin.

Summary of Contents for IRB 6400R

Page 4: ...Description 20 Product Specification IRB 1400 M97A BaseWare OS 3 0 ...

Page 6: ...Introduction 2 Product Manual ...

Page 10: ...Introduction 6 Product Manual ...

Page 12: ...Product Specification IRB 6400R 2 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 78: ...Accessories 68 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 80: ...Product Specification RobotWare 2 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 82: ...Introduction 4 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 104: ...Interbus S 3 2 26 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 110: ...I O Plus 3 2 32 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 128: ...PalletWare 50 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 132: ...Safety 2 Product Manual ...

Page 148: ...System Description CONTENTS Page 2 Product Manual ...

Page 158: ...Structure System Description 12 Product Manual ...

Page 160: ...Computer System System Description 14 Product Manual ...

Page 164: ...I O System System Description 18 Product Manual ...

Page 168: ...Safety System System Description 22 Product Manual ...

Page 170: ...External Axes System Description 24 Product Manual ...

Page 174: ...Installation and Commissioning CONTENTS Page 4 Product Manual IRB 6400R ...

Page 196: ...On Site Installation Installation and Commissioning 26 Product Manual IRB 6400R ...

Page 270: ...Installing the Control Program Installation and Commissioning 100 Product Manual IRB 6400R ...

Page 292: ...Maintenance CONTENTS Page 2 Product Manual IRB 6400R ...

Page 299: ...Maintenance Product Manual IRB 6400R 9 Figure 4 Lubricating gearbox axis 1 4 3 1 2 ...

Page 312: ...Troubleshooting Tools CONTENTS Page 2 Product Manual ...

Page 350: ...Troubleshooting Tools 40 Product Manual ...

Page 352: ...Fault tracing guide 2 Product Manual ...

Page 362: ...Fault tracing guide 12 Product Manual ...

Page 375: ...Motor units Repairs 12 Product Manual IRB 6400R ...

Page 401: ...Arm System Repairs 38 Product Manual IRB 6400R ...

Page 409: ...Cabling Repairs 46 Product Manual IRB 6400R ...

Page 441: ...Special Tools List Repairs 80 Product Manual IRB 6400R ...

Page 479: ...Part List and Spare Parts Product Manual IRB 6400R 38 ...

Page 480: ...Part List and Spare Parts Product Manual IRB 6400R 39 ...

Page 481: ...Part List and Spare Parts Product Manual IRB 6400R 40 ...