Repairs

Storing the values on the teach pendant

Product Manual IRB 6400R

73

11.2 Checking the calibration position

There are two ways to check the calibration position; both are described below.

Using the diskette, Controller Parameters:

Run the program \ SERVICE \ CALIBRAT \ CAL 6400 on the diskette, follow

instructions displayed on the teach pendant. When the robot stops, switch to MOTORS

OFF. Check that the calibration marks for each axis are at the same level, see Figure

37. If they are not, the setting of the revolution counters must be repeated.

Using the Jogging window on the teach pendant:

Open the Jogging window

and choose running axis-by-axis. Using the joystick,

move the robot so that the read-out of the positions is equal to zero. Check that the

calibration marks for each axis are at the same level, see Figure 37. If they are not, the

setting of the revolution counters must be repeated.

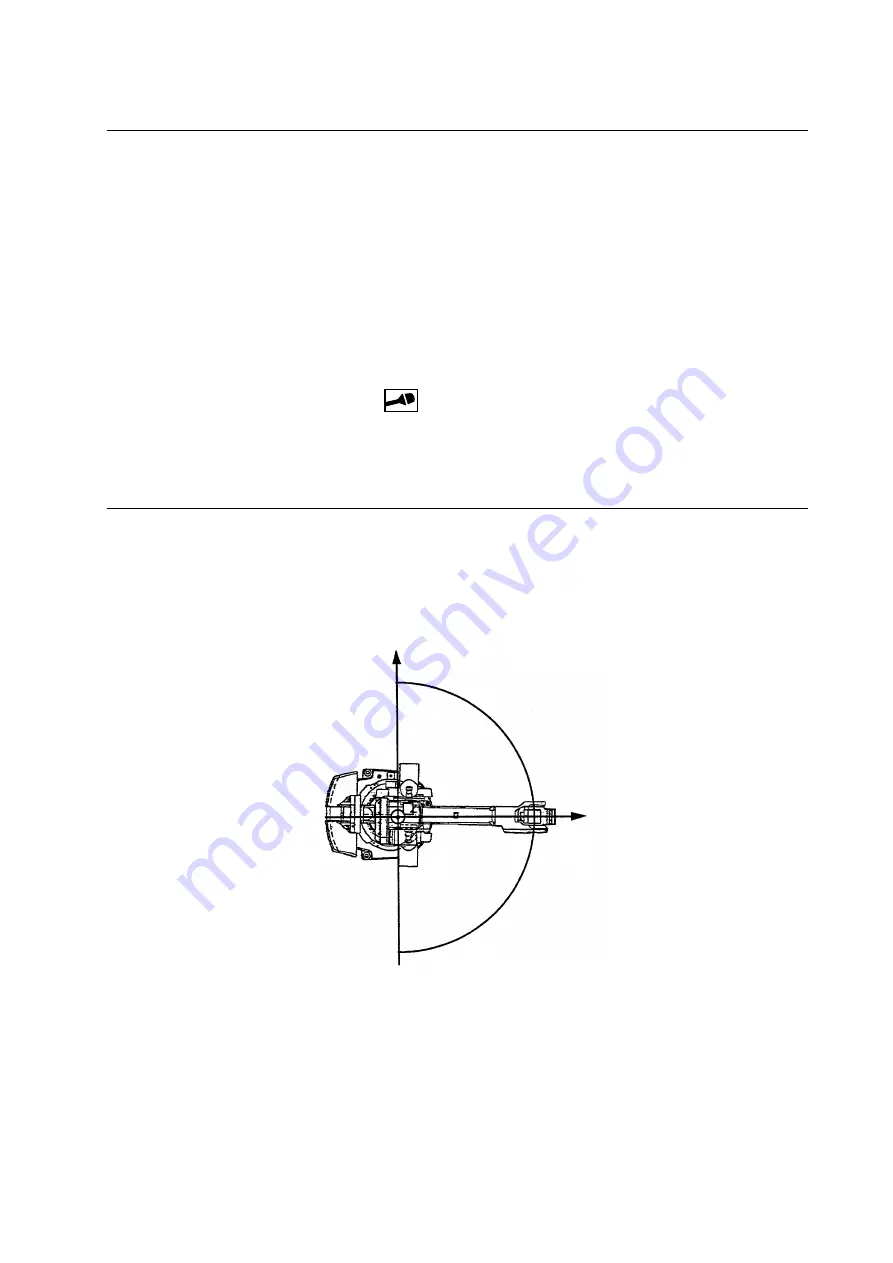

11.3 Alternative calibration positions

Before it can be calibrated in one of the two alternative positions, the robot must have

been calibrated with calibration equipment at calibration position 0 for all axes (the

robot is delivered with calibration position 0). See Figure 38.

Figure 38 Calibration positions 0, 1 and 2 (Normal, Right and Left)

Note!

If the final installation makes it impossible to reach the calibration 0 position, an

alternative calibration position must be set before installation.

Cal.pos. 0

Cal.pos. 1 -90

o

Cal.pos. 2 +90

o

Y

X

Left (1.570796)

Right (-1.570796)

Summary of Contents for IRB 6400R

Page 4: ...Description 20 Product Specification IRB 1400 M97A BaseWare OS 3 0 ...

Page 6: ...Introduction 2 Product Manual ...

Page 10: ...Introduction 6 Product Manual ...

Page 12: ...Product Specification IRB 6400R 2 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 78: ...Accessories 68 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 80: ...Product Specification RobotWare 2 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 82: ...Introduction 4 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 104: ...Interbus S 3 2 26 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 110: ...I O Plus 3 2 32 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 128: ...PalletWare 50 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 132: ...Safety 2 Product Manual ...

Page 148: ...System Description CONTENTS Page 2 Product Manual ...

Page 158: ...Structure System Description 12 Product Manual ...

Page 160: ...Computer System System Description 14 Product Manual ...

Page 164: ...I O System System Description 18 Product Manual ...

Page 168: ...Safety System System Description 22 Product Manual ...

Page 170: ...External Axes System Description 24 Product Manual ...

Page 174: ...Installation and Commissioning CONTENTS Page 4 Product Manual IRB 6400R ...

Page 196: ...On Site Installation Installation and Commissioning 26 Product Manual IRB 6400R ...

Page 270: ...Installing the Control Program Installation and Commissioning 100 Product Manual IRB 6400R ...

Page 292: ...Maintenance CONTENTS Page 2 Product Manual IRB 6400R ...

Page 299: ...Maintenance Product Manual IRB 6400R 9 Figure 4 Lubricating gearbox axis 1 4 3 1 2 ...

Page 312: ...Troubleshooting Tools CONTENTS Page 2 Product Manual ...

Page 350: ...Troubleshooting Tools 40 Product Manual ...

Page 352: ...Fault tracing guide 2 Product Manual ...

Page 362: ...Fault tracing guide 12 Product Manual ...

Page 375: ...Motor units Repairs 12 Product Manual IRB 6400R ...

Page 401: ...Arm System Repairs 38 Product Manual IRB 6400R ...

Page 409: ...Cabling Repairs 46 Product Manual IRB 6400R ...

Page 441: ...Special Tools List Repairs 80 Product Manual IRB 6400R ...

Page 479: ...Part List and Spare Parts Product Manual IRB 6400R 38 ...

Page 480: ...Part List and Spare Parts Product Manual IRB 6400R 39 ...

Page 481: ...Part List and Spare Parts Product Manual IRB 6400R 40 ...