On-Site Installation

Installation and Commissioning

22

Product Manual IRB 6400R

2.6.3 Position switch

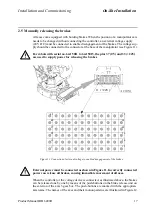

There are position switches fitted on axes 1-3. Instructions for fitting and adjusting the

cams and stops follow below.

The cams are mounted in whole lengths and must therefore be cut to suit the applica-

tion. Use a sharp knife and a rubber hammer, for example.

It is important that the entry edge on the cam is chamfered to an angle of max. 30°. If

the angle is larger there is a risk of damaging the position switch (see Figure 16).

The ends of the cam, that are in the channel of the profile, must be cut at an angle of

90° so that the contact area for the stop is as large as possible (see Figure 17).

When fitting the cam, it is important that the edges on the openings at the ends of the

profile are properly chamfered.

The cam stop comprises an M5 nut with an M5 x 6 stop screw. When the screw is

tighten into the material at the bottom of the profile, the nut is pushed up to the top of

the channel and forms a lock for the cam (see Figure 17).

Figure 16 Adjusting and locking the cams for the position breaker; the figure shows the position

breaker for axis 2.

1. Cam stop

3. Profile

1

2

3

30°

M5 x 6 stop screw

M5 nut

2. Adjustable cam

Summary of Contents for IRB 6400R

Page 4: ...Description 20 Product Specification IRB 1400 M97A BaseWare OS 3 0 ...

Page 6: ...Introduction 2 Product Manual ...

Page 10: ...Introduction 6 Product Manual ...

Page 12: ...Product Specification IRB 6400R 2 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 78: ...Accessories 68 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 80: ...Product Specification RobotWare 2 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 82: ...Introduction 4 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 104: ...Interbus S 3 2 26 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 110: ...I O Plus 3 2 32 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 128: ...PalletWare 50 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 132: ...Safety 2 Product Manual ...

Page 148: ...System Description CONTENTS Page 2 Product Manual ...

Page 158: ...Structure System Description 12 Product Manual ...

Page 160: ...Computer System System Description 14 Product Manual ...

Page 164: ...I O System System Description 18 Product Manual ...

Page 168: ...Safety System System Description 22 Product Manual ...

Page 170: ...External Axes System Description 24 Product Manual ...

Page 174: ...Installation and Commissioning CONTENTS Page 4 Product Manual IRB 6400R ...

Page 196: ...On Site Installation Installation and Commissioning 26 Product Manual IRB 6400R ...

Page 270: ...Installing the Control Program Installation and Commissioning 100 Product Manual IRB 6400R ...

Page 292: ...Maintenance CONTENTS Page 2 Product Manual IRB 6400R ...

Page 299: ...Maintenance Product Manual IRB 6400R 9 Figure 4 Lubricating gearbox axis 1 4 3 1 2 ...

Page 312: ...Troubleshooting Tools CONTENTS Page 2 Product Manual ...

Page 350: ...Troubleshooting Tools 40 Product Manual ...

Page 352: ...Fault tracing guide 2 Product Manual ...

Page 362: ...Fault tracing guide 12 Product Manual ...

Page 375: ...Motor units Repairs 12 Product Manual IRB 6400R ...

Page 401: ...Arm System Repairs 38 Product Manual IRB 6400R ...

Page 409: ...Cabling Repairs 46 Product Manual IRB 6400R ...

Page 441: ...Special Tools List Repairs 80 Product Manual IRB 6400R ...

Page 479: ...Part List and Spare Parts Product Manual IRB 6400R 38 ...

Page 480: ...Part List and Spare Parts Product Manual IRB 6400R 39 ...

Page 481: ...Part List and Spare Parts Product Manual IRB 6400R 40 ...