Troubleshooting Tools

Product Manual

31

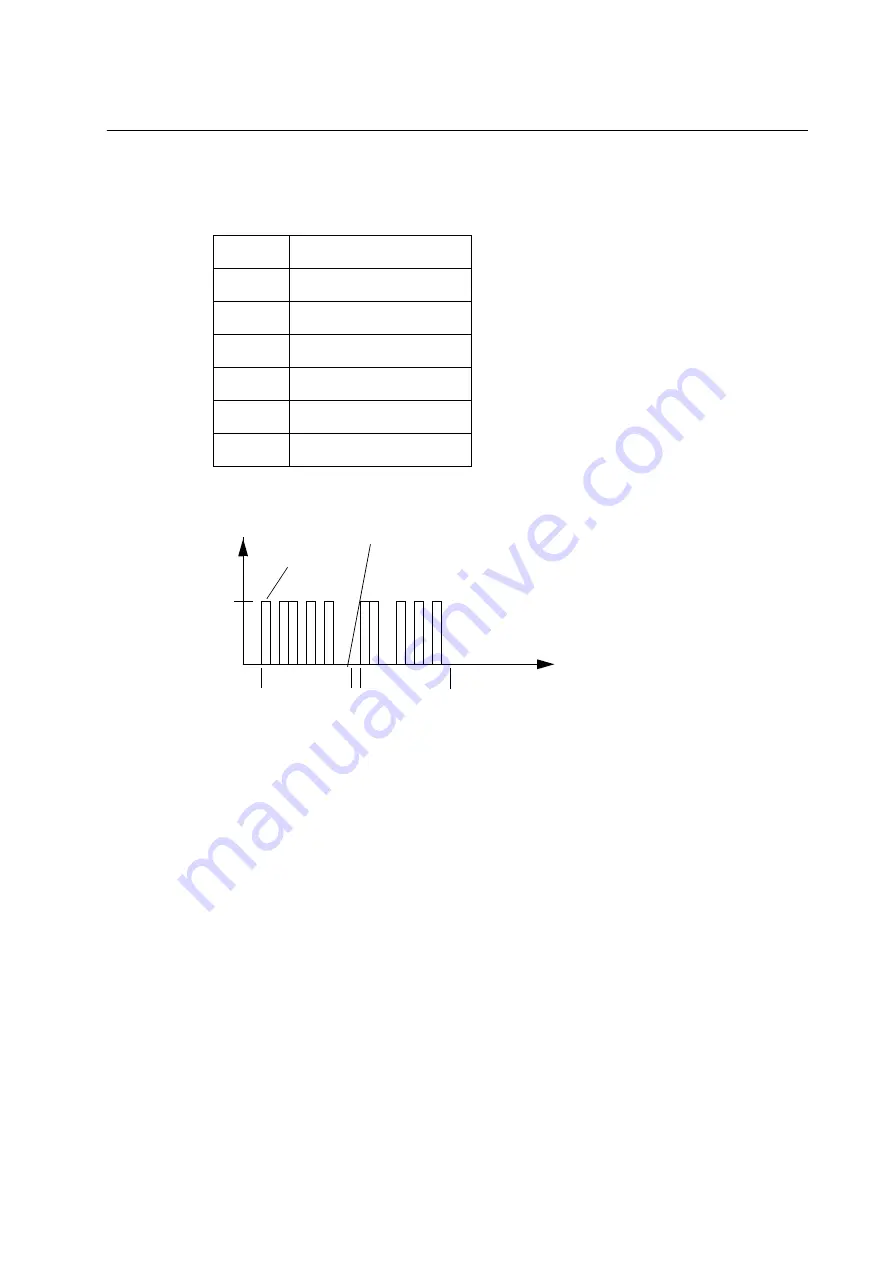

3.2 Signal description, RS 232 and RS 422

RS 232

Figure 2 Signal description for RS 232.

The transmission pattern can be single or bursts of 10 bit words, with one start bit “0”,

eight data bits (MSB first) and lastly one stop bit “1”.

Signal

Explanation

TXD

Transmit Data

RXD

Receive Data

DSR

Data Set Ready

DTR

Data Terminal Ready

CTS

Clear To Send

RTS

Request To Send

Start bit (“0”)

Stop bit (“1”)

f=9600/19200 baud

Byte 1

Byte 2

10 V

0 V

Summary of Contents for IRB 6400R

Page 4: ...Description 20 Product Specification IRB 1400 M97A BaseWare OS 3 0 ...

Page 6: ...Introduction 2 Product Manual ...

Page 10: ...Introduction 6 Product Manual ...

Page 12: ...Product Specification IRB 6400R 2 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 78: ...Accessories 68 Product Specification IRB 6400R M99 BaseWare OS 3 2 ...

Page 80: ...Product Specification RobotWare 2 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 82: ...Introduction 4 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 104: ...Interbus S 3 2 26 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 110: ...I O Plus 3 2 32 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 128: ...PalletWare 50 Product Specification RobotWare for BaseWare OS 3 2 ...

Page 132: ...Safety 2 Product Manual ...

Page 148: ...System Description CONTENTS Page 2 Product Manual ...

Page 158: ...Structure System Description 12 Product Manual ...

Page 160: ...Computer System System Description 14 Product Manual ...

Page 164: ...I O System System Description 18 Product Manual ...

Page 168: ...Safety System System Description 22 Product Manual ...

Page 170: ...External Axes System Description 24 Product Manual ...

Page 174: ...Installation and Commissioning CONTENTS Page 4 Product Manual IRB 6400R ...

Page 196: ...On Site Installation Installation and Commissioning 26 Product Manual IRB 6400R ...

Page 270: ...Installing the Control Program Installation and Commissioning 100 Product Manual IRB 6400R ...

Page 292: ...Maintenance CONTENTS Page 2 Product Manual IRB 6400R ...

Page 299: ...Maintenance Product Manual IRB 6400R 9 Figure 4 Lubricating gearbox axis 1 4 3 1 2 ...

Page 312: ...Troubleshooting Tools CONTENTS Page 2 Product Manual ...

Page 350: ...Troubleshooting Tools 40 Product Manual ...

Page 352: ...Fault tracing guide 2 Product Manual ...

Page 362: ...Fault tracing guide 12 Product Manual ...

Page 375: ...Motor units Repairs 12 Product Manual IRB 6400R ...

Page 401: ...Arm System Repairs 38 Product Manual IRB 6400R ...

Page 409: ...Cabling Repairs 46 Product Manual IRB 6400R ...

Page 441: ...Special Tools List Repairs 80 Product Manual IRB 6400R ...

Page 479: ...Part List and Spare Parts Product Manual IRB 6400R 38 ...

Page 480: ...Part List and Spare Parts Product Manual IRB 6400R 39 ...

Page 481: ...Part List and Spare Parts Product Manual IRB 6400R 40 ...