3 Maintenance

3.3.13. Inspection, position switch axes 1, 2 and 3

171

3HAC023082-001 Revision: E

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

3.3.13. Inspection, position switch axes 1, 2 and 3

Position switches, axes 1-3

The position switches are shown, fitted to the robot, in section

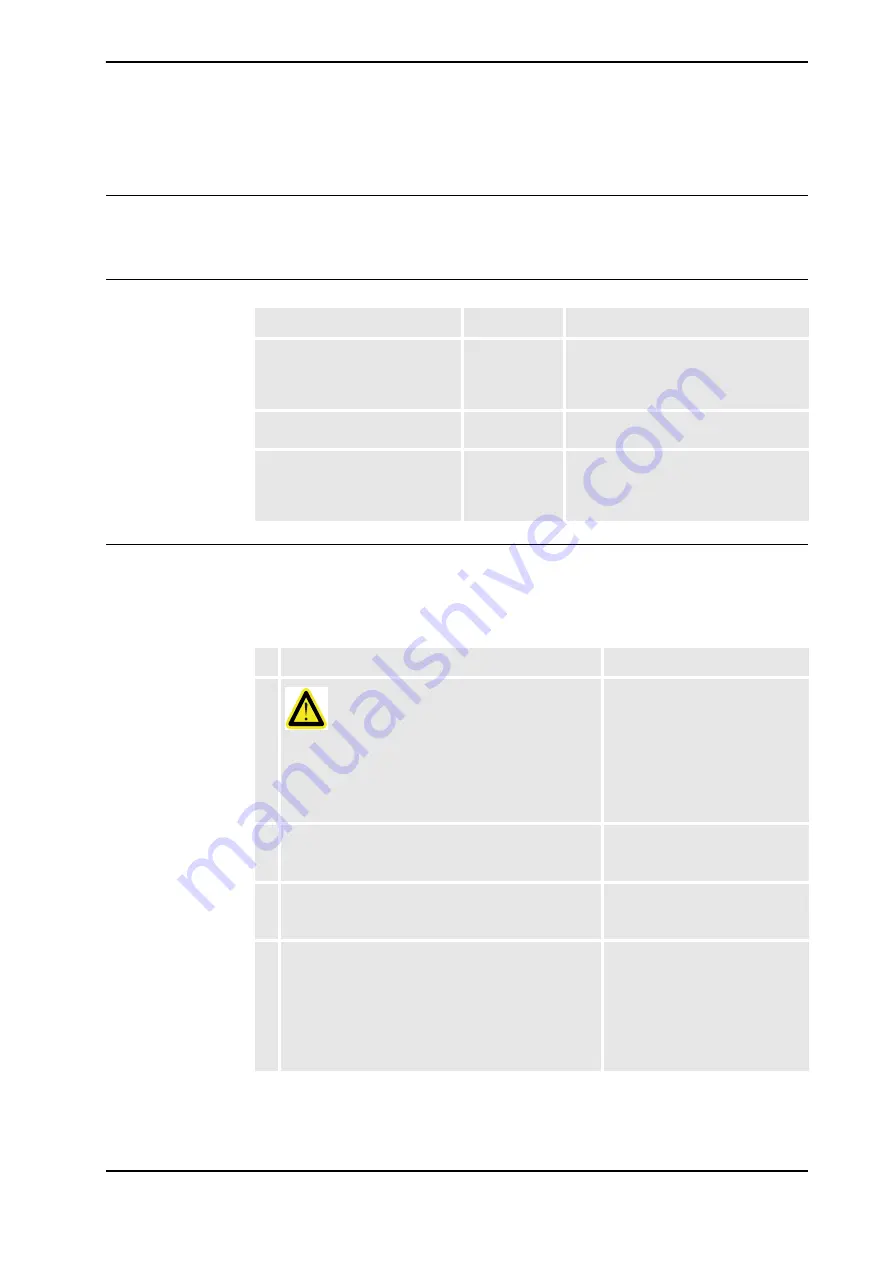

Required equipment

Inspection, position switches

The procedure below details how to inspect the position switch, axes 1, 2 and 3.

See the figures in section

Installation of position switches (option) on page 111

to locate the

different components to be inspected.

Equipment, etc.

Art. no.

Note

Position switch, axes 1-3

-

The article numbers of the position

switches are specified in section

lation of position switches (option) on

page 111

Standard toolkit

-

The contents are defined in section

.

Other tools and procedures may

be required. See references to

these procedures in the step-by-

step instructions below.

These procedures include references to

the tools required.

Action

Note

1.

DANGER!

Turn off all electric power, hydraulic and pneumatic

pressure supplies to the robot!

For Foundry Prime robots: Do not turn off the air

pressure to motors and SMB.

2. Check the position switch!

•

Check that the rollers are easy to push in and

that they roll freely.

3. Check the rail!

•

Check that the rail is firmly attached with the

attachment screws.

4. Check the cams!

•

Check that the rollers have not caused any

impressions on the cams.

•

Check that the cams are clean. Wipe them if

necessary!

•

Check that the set screws holding the cams in

position are firmly attached.

Continues on next page

Summary of Contents for IRB 6600 - 175/2.8 type B

Page 2: ......

Page 10: ...Table of Contents 8 3HAC023082 001 Revision E Copyright 2004 2008 ABB All rights reserved ...

Page 532: ......