4 Repair

4.4.1. Replacement of turning disk, IRB 6600 and IRB 6650

275

3HAC023082-001 Revision: E

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

Removal, turning disk

The procedure below details how to remove the turning disk.

Refitting, turning disk

The procedure below details how to refit the turning disk.

Action

Note

1.

DANGER!

Turn off all electric power, hydraulic and pneumatic

pressure supplies to the robot!

For Foundry Prime robots: Do not turn off the air

pressure to motors and SMB.

2. Remove any equipment fitted to the turning disk.

3. Run the robot to a position where the

oil plug, draining

of axis 6 gearbox faces downwards.

Shown in the figure

!

4. Drain the oil from gearbox 6.

Detailed in section

.

5. Remove the turning disk by unscrewing its

attachment screws

.

Shown in the figure

!

Action

Note/Illustration

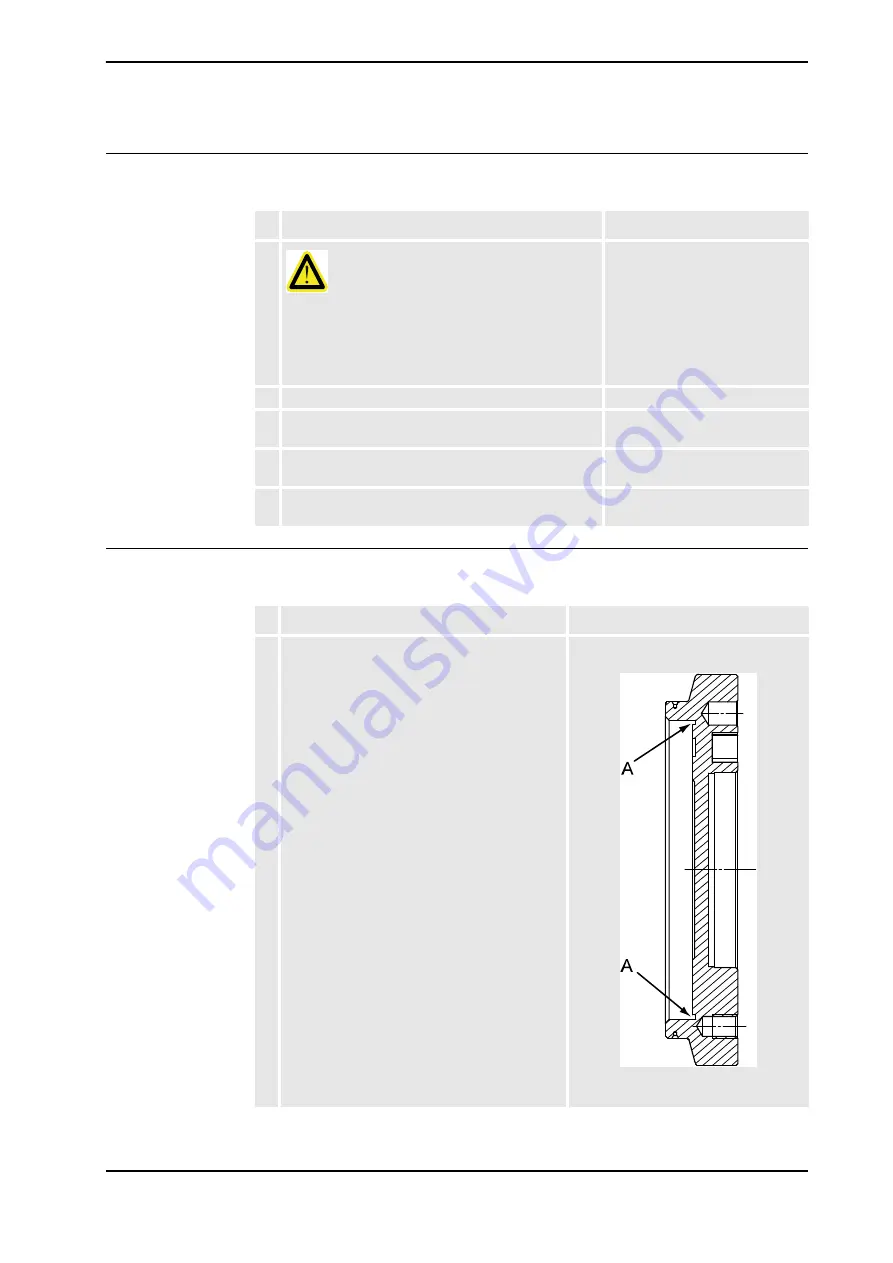

1. Lubricate the turning disk

o-ring

with

grease.

Fit the o-ring to the rear of the turning disk.

Fit also the 12 o-rings, when refitting the

attachment screws.

Art. no. is specified in

!

xx0200000218

•

A: Sealing surface, o-ring

Continued

Continues on next page

Summary of Contents for IRB 6600 - 175/2.8 type B

Page 2: ......

Page 10: ...Table of Contents 8 3HAC023082 001 Revision E Copyright 2004 2008 ABB All rights reserved ...

Page 532: ......