4 Repair

4.7.2. Replacement of gearbox axis 2

395

3HAC023082-001 Revision: E

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

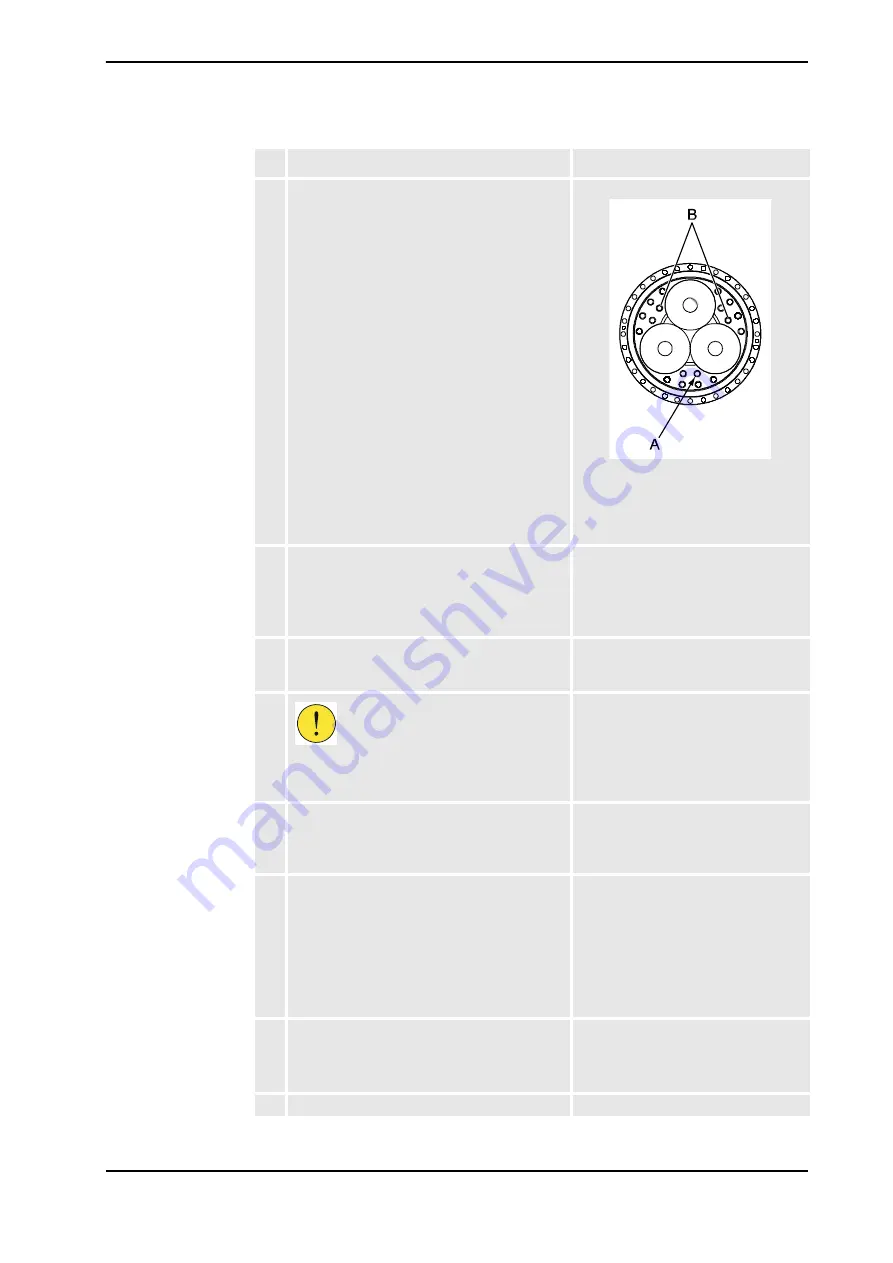

4. Fit the

guide pins, sealing axis 2/3

to the rear

of the gearbox, axis 2.

Use the attachment holes shown in the figure

to the right!

xx0300000552

•

A: Rear attachment screws,

gearbox (18 pcs)

•

B: Holes for the guide pins,

sealing axis 2/3 on the gearbox

5. Fit the new

sealing, axis 2/3

on to the guide

pins on the gearbox.

Note!

Do not remove the guide pins for the

sealing until the rear attachment screws are

secured.

Art. no. is specified in

!

6. Fit two

guide pins, M12

in 180° relation to each

other in the frame, in the screw holes for the

gearboxes front attachment screws.

Art. no. is specified in

!

7.

CAUTION!

The gearbox weighs 100 kg! All lifting

equipment used must be sized accordingly!

8. Lift the gearbox to its mounting position and

slide it onto the guiding pins attached in the

frame, through the front attachment screw

holes.

9. Align the gearbox attachment screw holes to

the hole patterns in the lower arm, with help

from the guide pins, sealing axis 2/3.

If necessary, use a

gearbox crank

to turn the

gear!

Use the gearbox crank with caution! The

gearbox may be damaged if the crank is

inserted too far into the gear!

Art. no. is specified in

!

10. Fit the gearbox with guidance from the guide

pins and slide it into position.

If necessary, use the front gearbox attachment

screws to press the gearbox into place.

11. Remove the lifting tool from the gearbox.

Action

Note/Illustration

Continued

Continues on next page

Summary of Contents for IRB 6600 - 175/2.8 type B

Page 2: ......

Page 10: ...Table of Contents 8 3HAC023082 001 Revision E Copyright 2004 2008 ABB All rights reserved ...

Page 532: ......