4 Repair

4.7.2. Replacement gearbox axis 2

239

3HAC027151-001 Revision: B

©

Co

py

rig

h

t 200

6-

200

8 ABB. All righ

ts reser

v

ed.

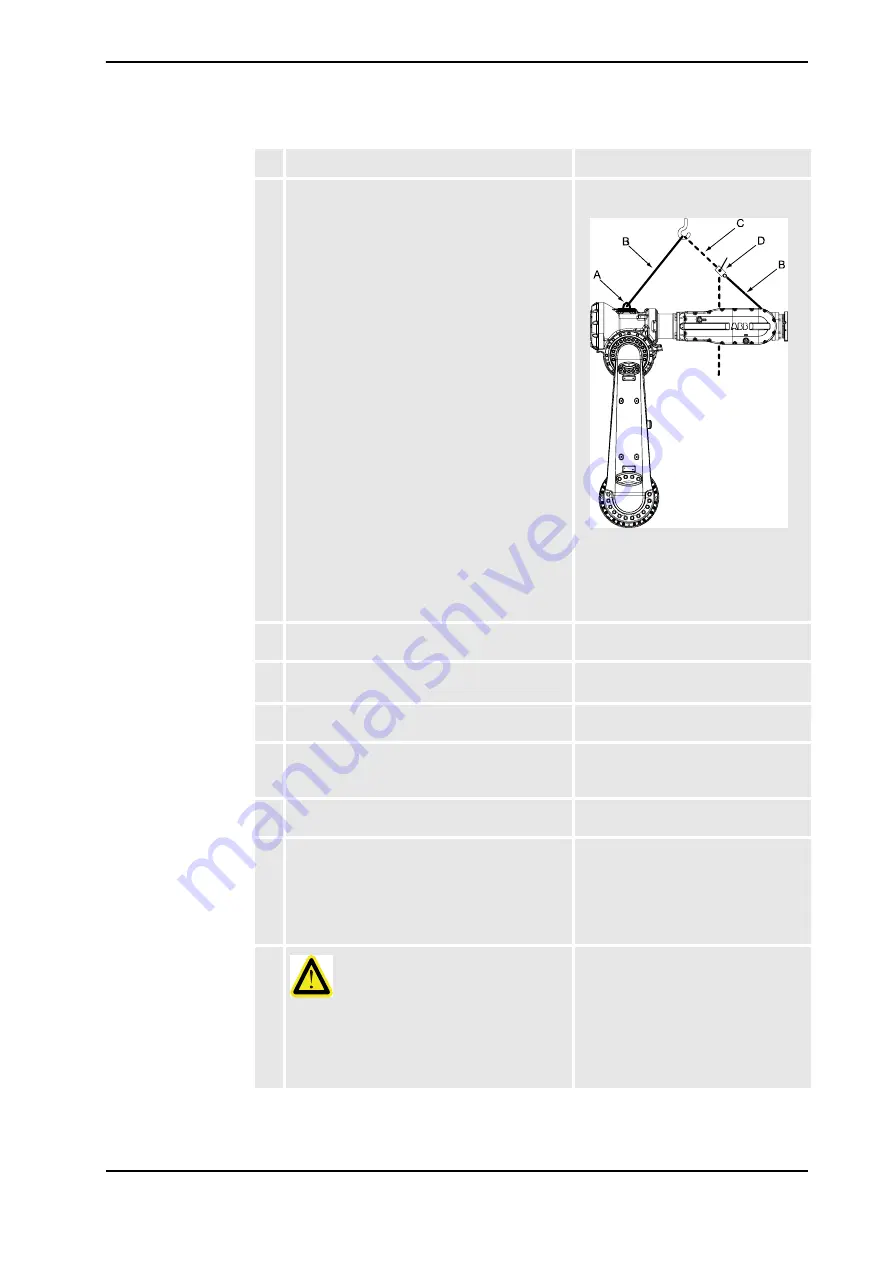

8. Fit the

lifting tool

on the upper arm and secure

the robot in an overhead crane and lift it

carefully up to its mounting position.

Art. no. is specified in

xx0600003099

•

A : Lifting tool

•

B : Roundsling

•

C : Lifting chain

•

D : Hoisting block

9. Use a crank in the gearbox in order to find the

holes for the attachment screws.

10. Refit the lower arm to the gearbox axis 2 with its

attachment screws.

M16x50 (16 pcs)

Tightening torque: 300 Nm.

11. Refit motor axis 2.

Detailed in section

.

12. Refit the cable harness, axes 1-3.

Detailed in section

cable harness, lower end (axes 1-2) on

page 153

.

13. Fill the gearbox axis 2 with oil.

Detailed in section

.

14. Recalibrate the robot.

Calibration is detailed in a separate

calibration manual, enclosed with the

calibration tools.

General calibration information is

included in section

Calibration infor-

mation

.

15.

DANGER!

Make sure all safety requirements are met

when performing the first test run. These are

further detailed in section

run may cause injury or damage! on page 33

Action

Note

Continued