2.5.5 Lifting the base plate

Required equipment

Note

Article number

Equipment

3 pcs

3HAC14457-4

Lifting eye, M16

Length: approx. 2 m

Lifting slings

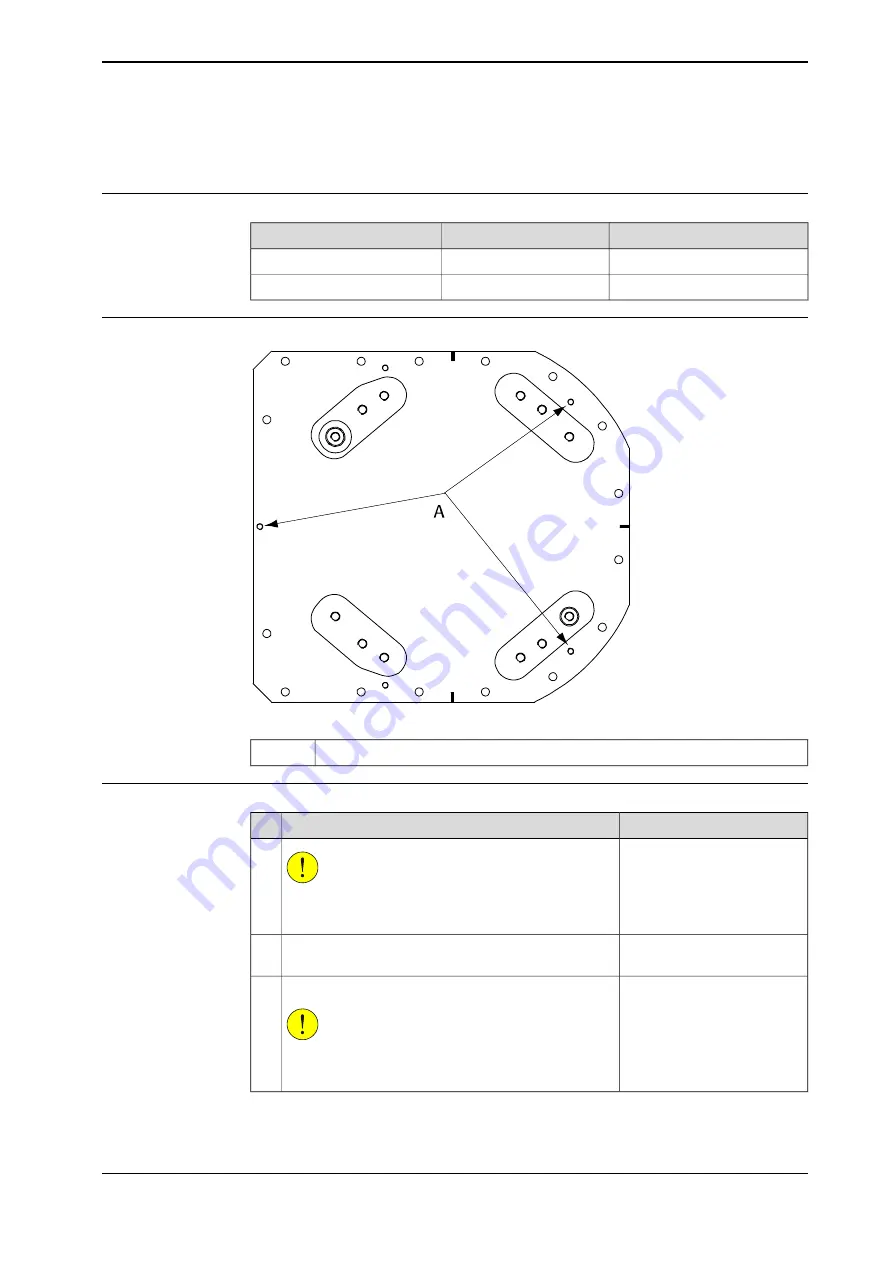

Hole configuration

xx0200000096

Attachment holes for lifting eyes (x3)

A

Lifting, base plate

Note

Action

CAUTION

The base plate weighs 353 kg. All lifting accessories

used must be sized accordingly.

1

Shown in figure

.

Fit lifting eyes in specified holes.

2

Fit lifting slings to the eyes and to the lifting accessory.

CAUTION

Lift and move the base plate very slowly. If the base

plate starts to swing it is a risk for injuries or damage.

3

Product manual - IRB 6620

81

3HAC027151-001 Revision: T

© Copyright 2006-2018 ABB. All rights reserved.

2 Installation and commissioning

2.5.5 Lifting the base plate

Summary of Contents for IRB 6620

Page 1: ...ROBOTICS Product manual IRB 6620 ...

Page 8: ...This page is intentionally left blank ...

Page 176: ...This page is intentionally left blank ...

Page 338: ...This page is intentionally left blank ...

Page 350: ...This page is intentionally left blank ...

Page 352: ...This page is intentionally left blank ...

Page 358: ......

Page 359: ......